Production process of ringent fish maw

A production process and fish maw technology, which is applied in fish processing, food processing, fish cleaning/descaling, etc. It can solve the problems of poor aesthetics, high blood content in fish maw, heavy fishy smell, etc., and increase the thermal contact surface area , Improve the appearance and taste, the color is bright yellow and shiny

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A kind of production technology of opening fish maw, comprises the following steps:

[0047] S1. Cleaning

[0048] 1) Cleaning with a high-pressure cleaner: Put the fish maw to be cleaned in a high-pressure cleaner to clean the surface and interior of the fish maw. The cleaning temperature of the high-pressure cleaner is 12-18°C.

[0049] 2) Washing with normal saline: mix with normal saline at 2-6°C, pour in the same amount of fish maw, and stir with a mixer for 60 minutes.

[0050] 3) Washing with clean water: Pour the fish maw into clean water at 2-6°C equal to the fish maw, and stir for 60 minutes with a mixer.

[0051] 4) Steps 2) and 3) were repeated twice.

[0052] S2. Trim processing

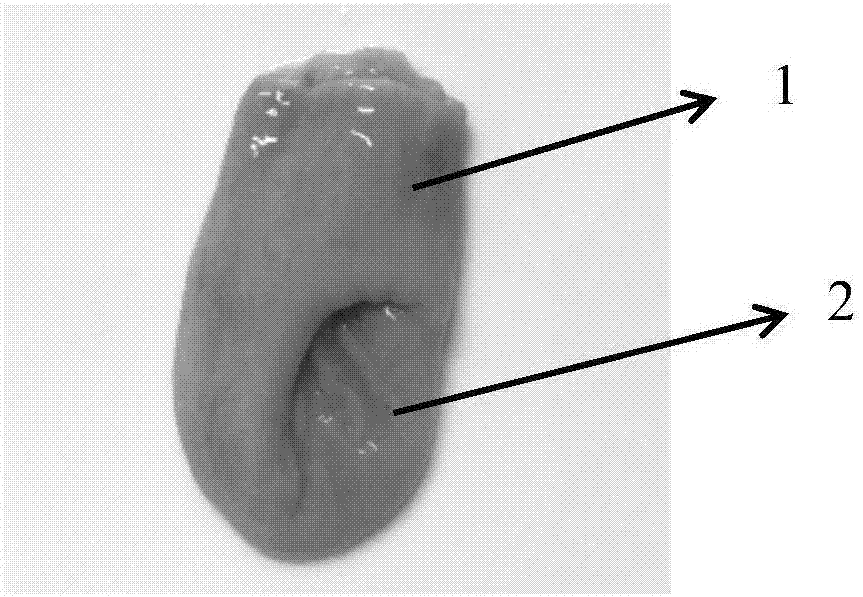

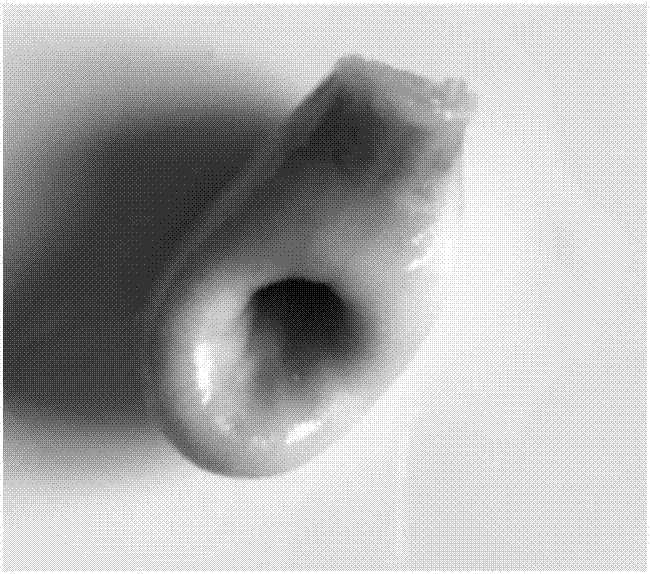

[0053] Such as image 3 As shown, cut off the fat of the fish maw, and cut a knife from the bottom to the top of the fish maw.

[0054] S3. Second cleaning

[0055] The trimmed fish maw is cleaned by a high-pressure cleaner, the cleaning temperature of the high-pressure clea...

Embodiment 2

[0063] A kind of production technology of opening fish maw, comprises the following steps:

[0064] S1. Cleaning

[0065] 1) Cleaning with a high-pressure cleaner: Put the fish maw to be cleaned in a high-pressure cleaner to clean the surface and interior of the fish maw. The cleaning temperature of the high-pressure cleaner is 12-18°C.

[0066] 2) Washing with normal saline: Mix the normal saline at 2-6°C, pour in the same amount of fish maw, and stir for 40 minutes with a mixer.

[0067] 3) Cleaning with clean water: Pour the fish maw into clean water at 2-6°C equal to the fish maw, and stir for 40 minutes with a mixer.

[0068] 4) Steps 2) and 3) were repeated once.

[0069] S2. Trim processing

[0070] Such as Figure 5 As shown, cut off the fat of the fish maw, and cut a knife on the top of the fish maw.

[0071] S3. Second cleaning

[0072] The trimmed fish maw is cleaned by a high-pressure cleaner, the cleaning temperature of the high-pressure cleaner is 12-18° C., ...

Embodiment 3

[0080] Such as Image 6 Shown, when pruning, respectively cut a knife above and below the fish maw, and other steps are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com