Environment-friendly efficient intelligent reaction kettle for liquid mixing reaction

A liquid mixing and reaction kettle technology, applied in chemical/physical/physical-chemical stationary reactors, chemical/physical/physical-chemical processes, chemical instruments and methods, etc., can solve the problem of poor stirring reaction effect and low reaction product yield , It is easy to cause local reactions and other problems to achieve the effect of ensuring sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

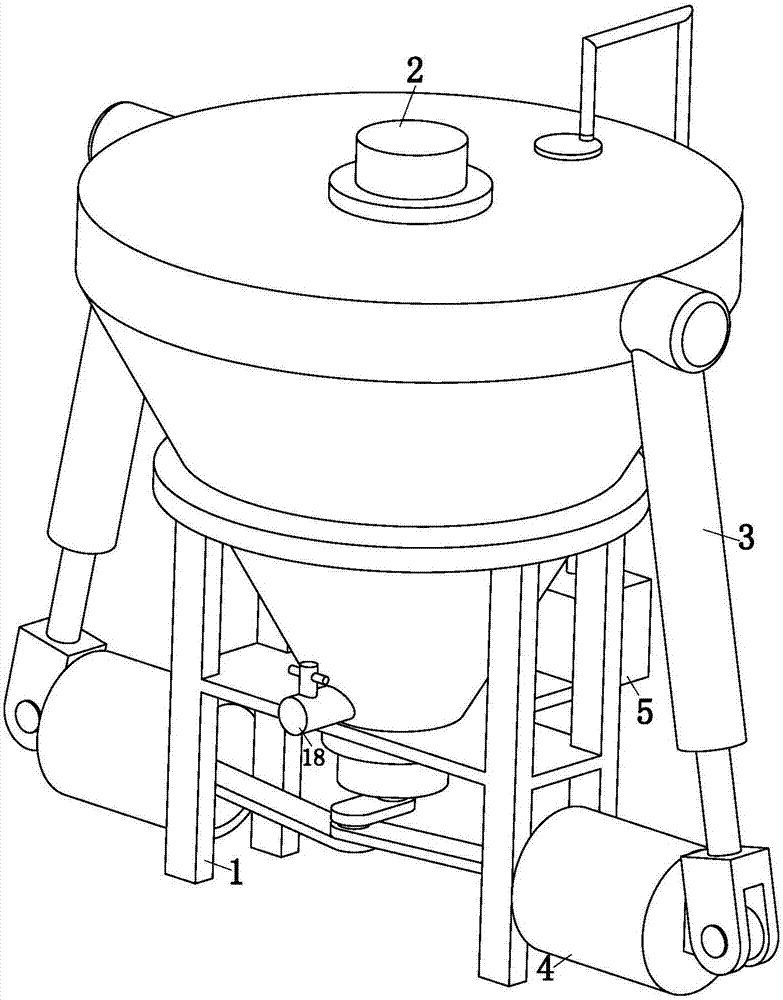

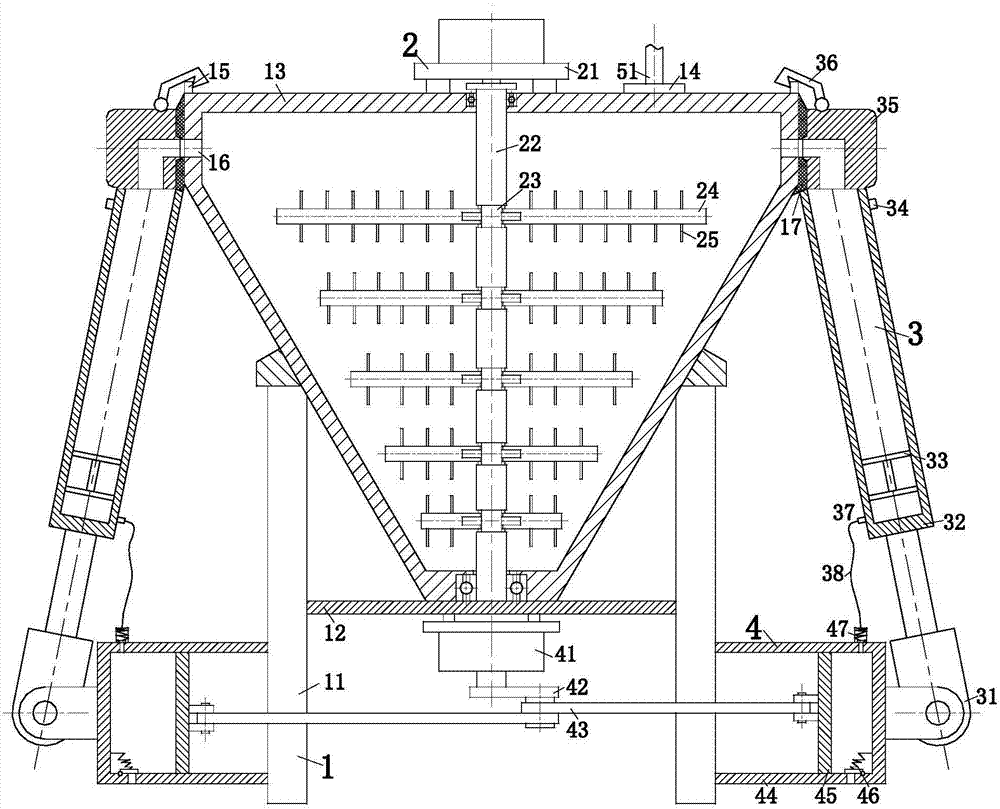

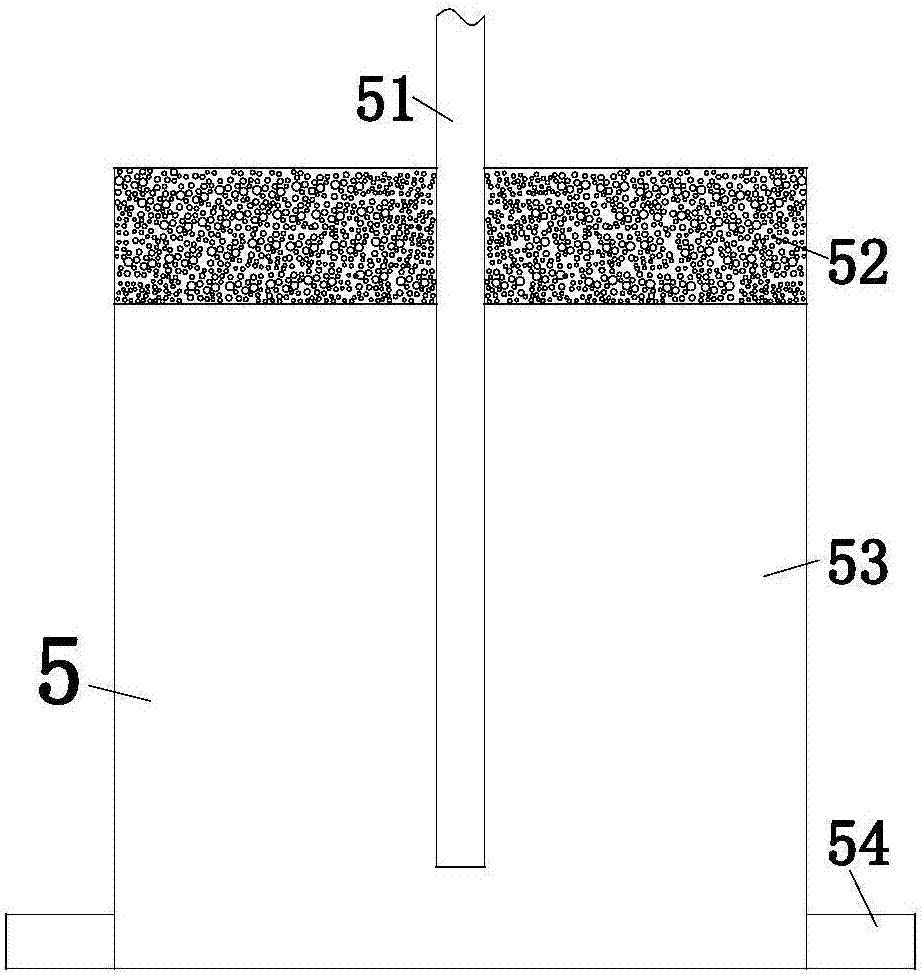

[0028] Such as Figure 1 to Figure 4 As shown, a kind of environment-friendly liquid mixed reaction of the present invention is used for efficient intelligent reactor, comprises reactor body 1, stirring unit 2, supply unit 3, power unit 4 and tail gas treatment unit 5; Described reactor body 1 can provide a reaction site for the liquid reaction, and at the same time provide an installation fulcrum for the reaction kettle; the stirring unit 2 is connected to the reaction kettle body 1, and the stirring unit 2 can realize multi-free rotation and stirring of the liquid in the reaction kettle, and can realize Fully stirring the liquid reactants; the supply unit 3 is evenly arranged along the periphery of the reactor body 1, and the supply unit 3 can i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com