Cloth dye power manufacturing device

A technology for dyeing dyes and making devices, which is applied in the direction of grain processing, etc., which can solve the problems of uneven particle size of dye powder and inconvenient dye dissolving process, and achieve the effect of good uniformity and high crushing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

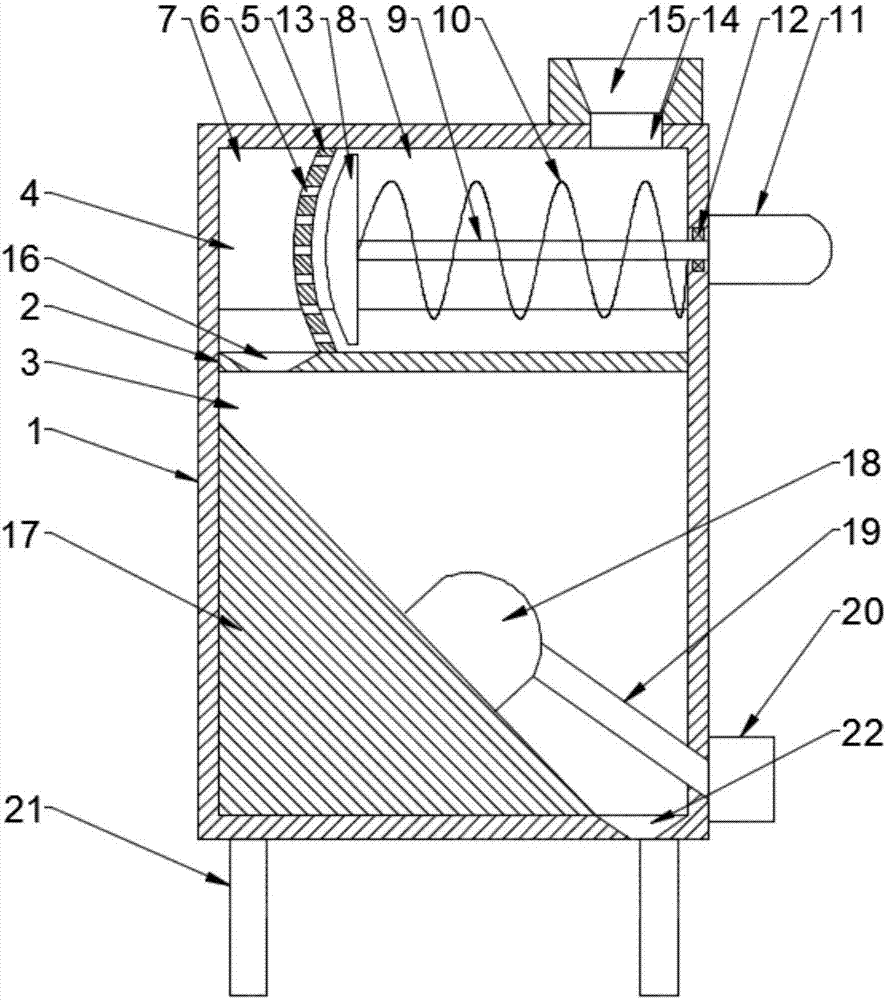

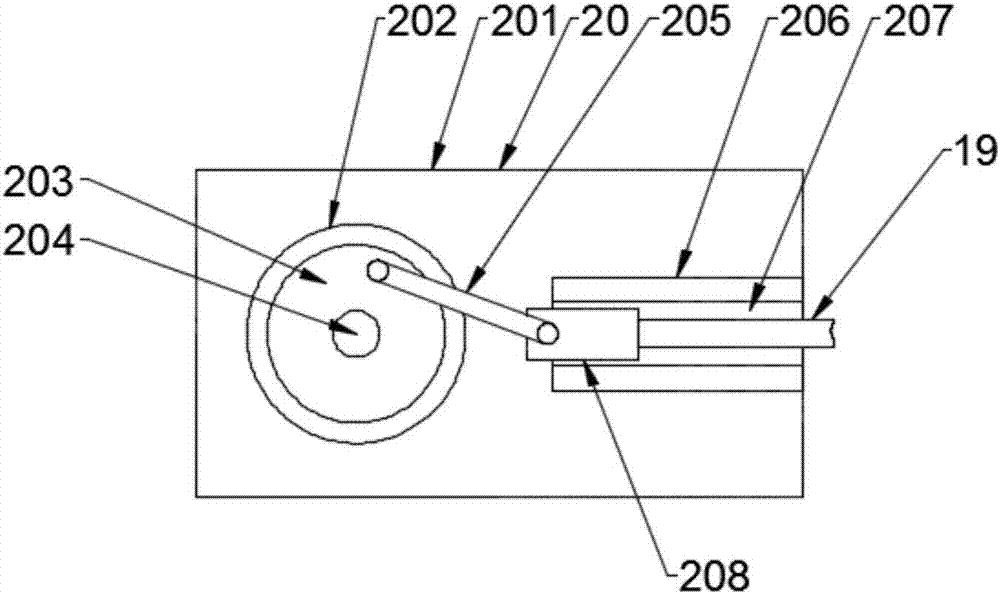

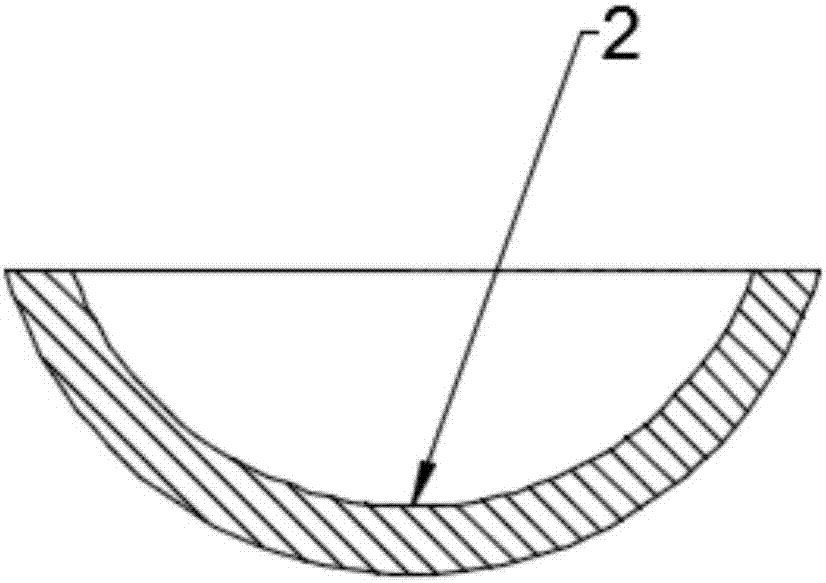

[0019] see Figure 1~3 , a cloth dyeing dye powder manufacturing device, comprising a body 1, the upper part of the inner cavity of the body 1 is provided with a partition 2, the partition 2 is a curved plate, and the partition 2 divides the inner cavity of the body 1 into lower Chamber 3 and upper chamber 4, described upper chamber 4 is arranged on the top of lower chamber 3, is provided with grinding plate 5 in upper chamber 4, and described grinding plate 5 is arc-shaped plate, and even on the grinding plate 5 A number of screening holes 6 are provided, and the upper chamber 4 is divided into a left chamber 7 and a right chamber 8 by a grinding plate 5. A rotating shaft 9 is arranged in the right chamber 8, and a crushing blade 10 is set on the rotating shaft 9. , the crushing blade 10 is a spiral structure designed to advance to the left, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com