Centrifugal machine for teaching experiments

A technology of centrifuge and clamping mechanism, which is applied in the field of centrifuges, can solve the problems of inconvenient carrying and handling, large volume of centrifuges, and inconvenient teaching, and achieve the effects of good sound insulation and shock absorption, small size, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

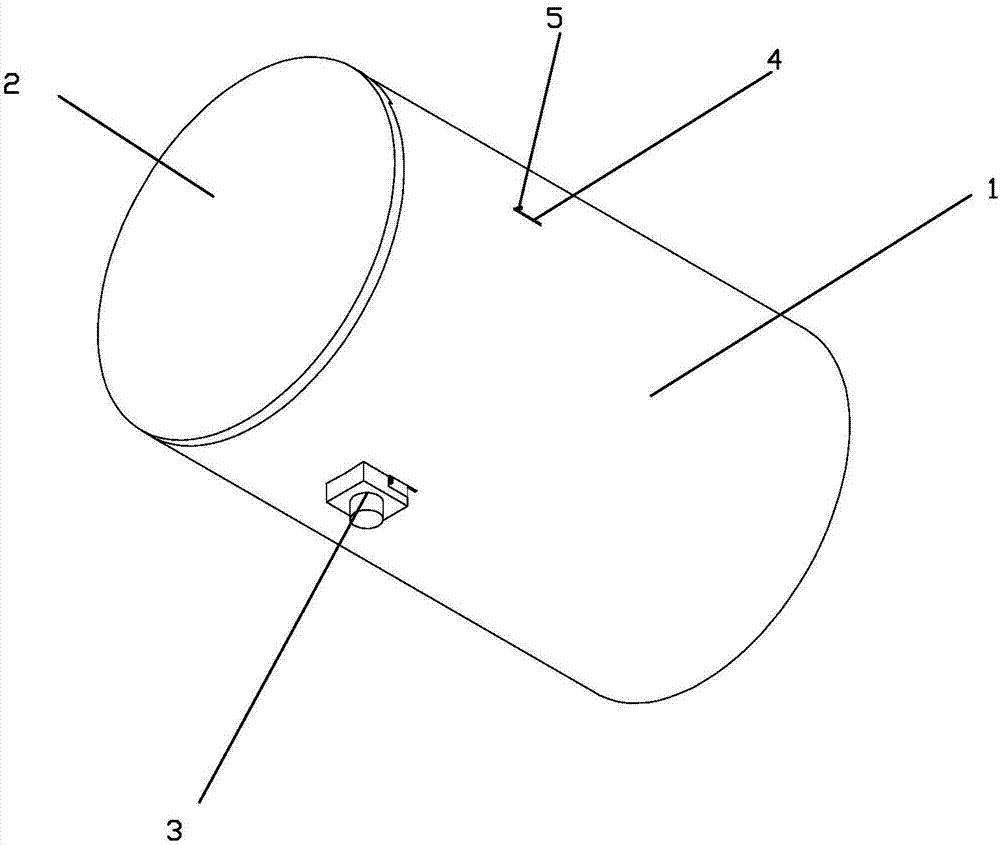

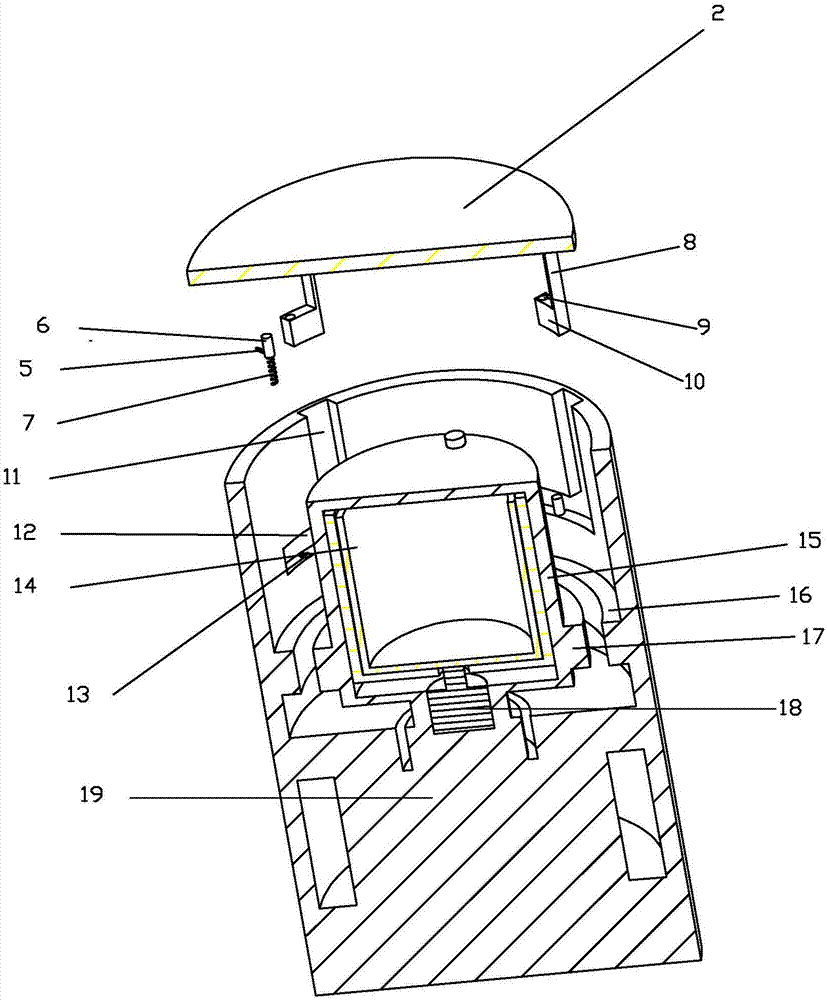

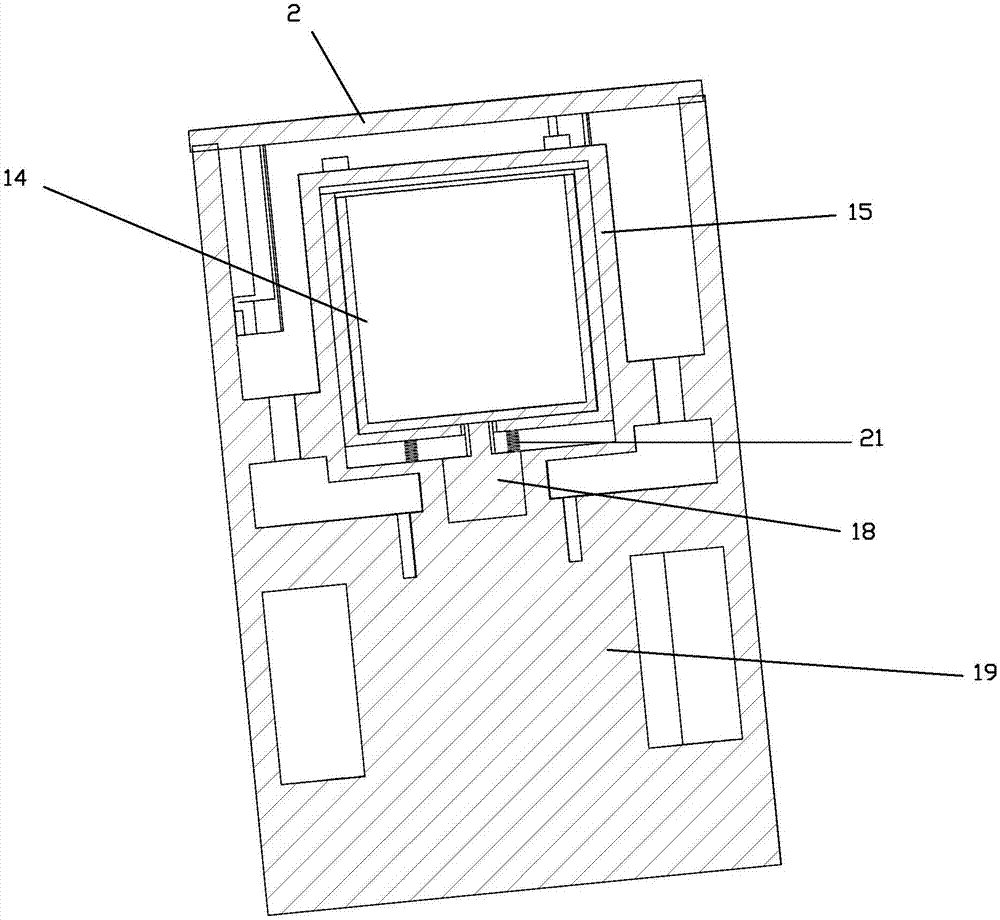

[0021] Such as Figures 1 to 4 A centrifuge with good use effect shown includes a casing 1, a first motor 19 is provided on the inner bottom of the casing 1, and a solid particle or liquid and liquid can be placed on the motor. The container 14 of the mixture is provided with a cover 2 on the upper surface of the shell 1, and a quick snap-in mechanism is provided between the cover 2 and the shell 1 to allow the cover 2 to be quickly installed on the shell 1. The clamping mechanism can quickly install the cover on the shell, with good sealing performance, simple installation, good sound insulation and shock absorption effect, and no liquid will spill out during use.

[0022] The quick locking mechanism of the present invention includes a plurality of longitudinal through grooves 11 arranged on the inner wall of the outer shell 1 and penet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com