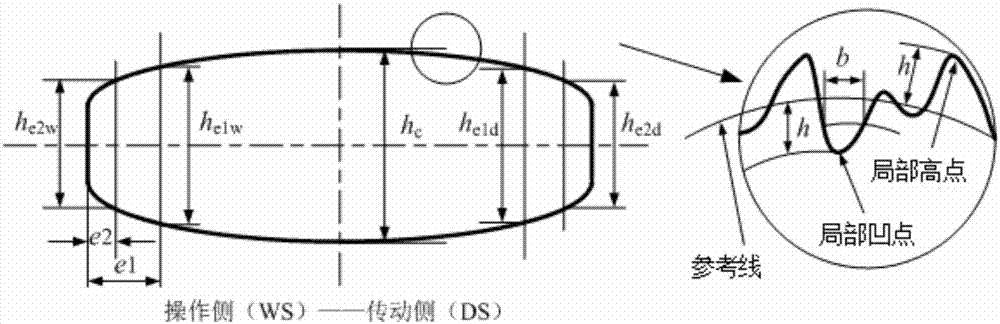

Plate and strip cross section local high and sinking point on-line identification method

An identification method and a technology of local high points, which are applied in the field of strip rolling, can solve the problems of inability to evaluate and determine the value of high (concave) points of the strip online, and achieve the effect of ensuring data validity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to further elaborate the above-mentioned technical solution, the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific examples. The limitation of the technical solution of the invention, in the case of no conflict, the embodiments of the present invention and the technical features in the embodiments can be combined with each other.

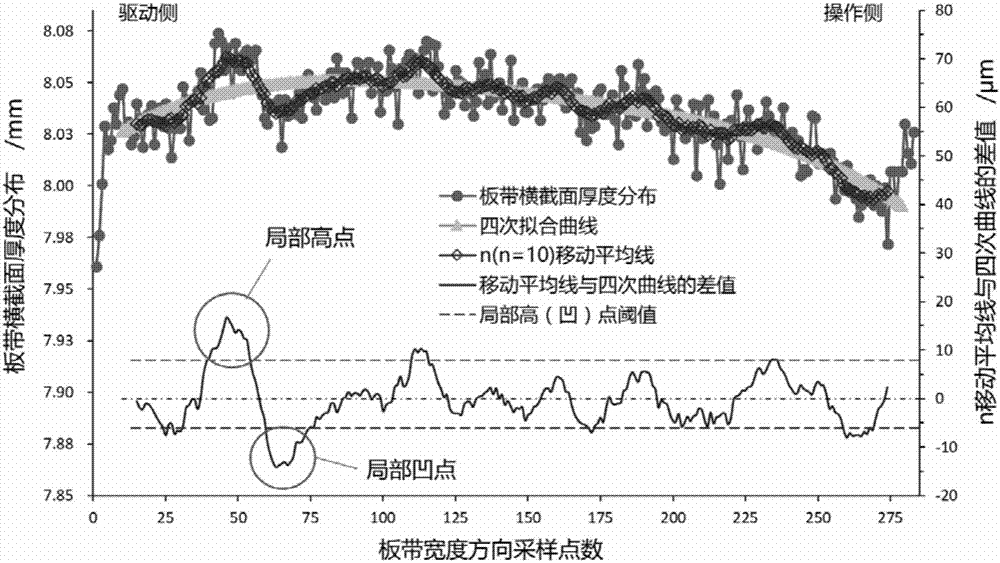

[0054] The schematic diagram of the on-line identification method of the local high (concave) point in the strip cross section provided by the invention is as follows figure 2 shown. exist figure 2 On the basis of, this embodiment specifically includes the following steps:

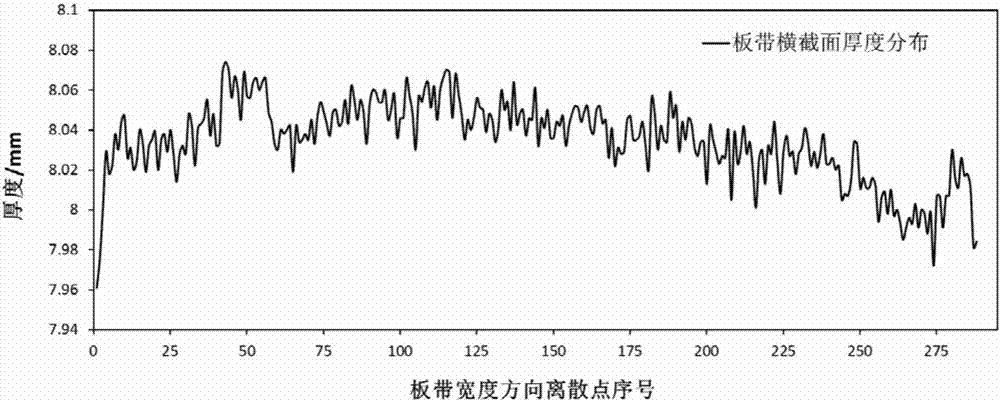

[0055] Step S1: Obtain the thickness distribution data of the full width of a strip cross-section from the online multifunctional instrument or control system, that is, the thickness value of the strip width equidistant dispersion, such as image 3 shown. The strip width ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com