Coating, drying and sanding production line for wood decorative line

A wood decoration and production line technology, which is applied in the direction of coating, abrasive belt grinder, grinding machine parts, etc., can solve the problems that wooden slats cannot be sanded, and the method is not ideal, so as to improve the effect of sanding operation and the back surface Smooth and flat, improve the effect of sanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

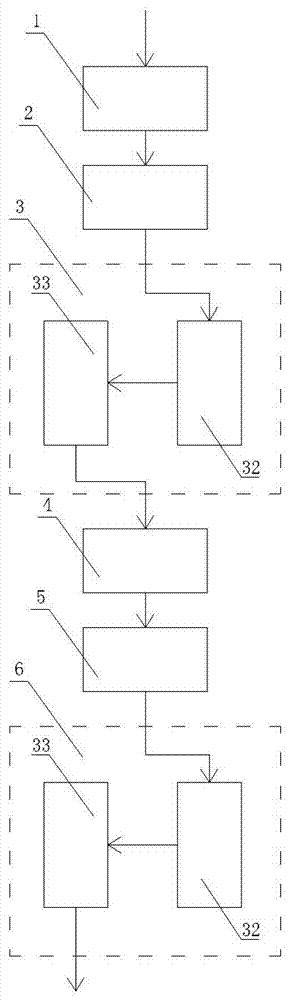

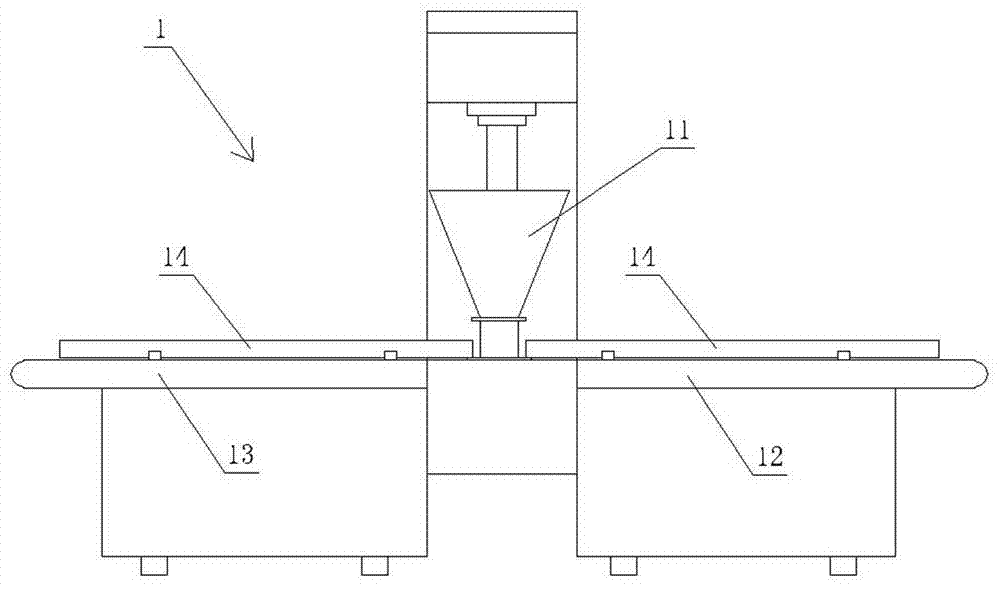

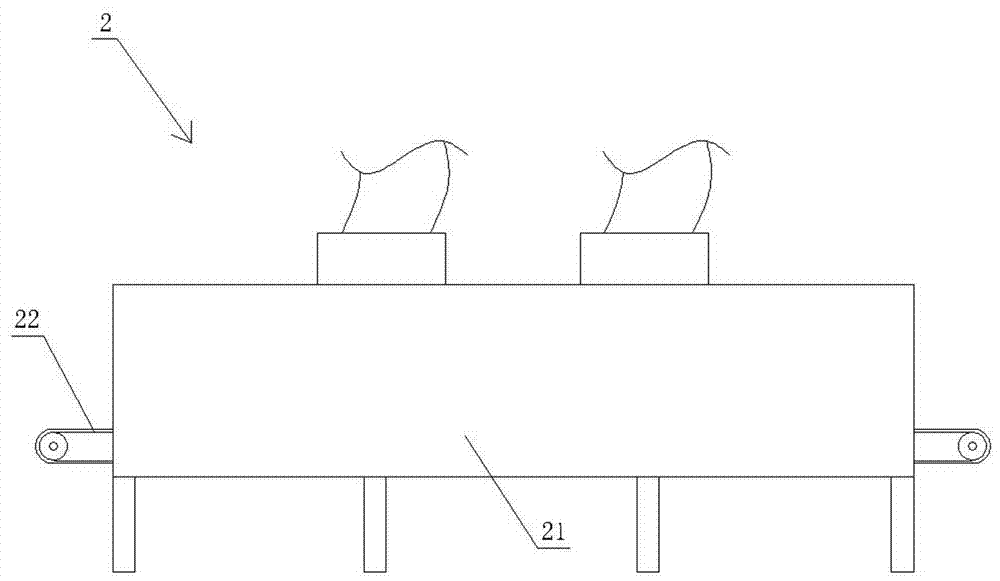

[0022] Refer to attached figure 1 , figure 2 , image 3 with Figure 4 . A coating, drying and sanding production line for wooden decorative moldings, including a first coating machine 1 for coating wooden slats for the first time, for accepting wooden slats from the first coating machine 1 and performing the first coating operation on them. The first dryer 2 for drying operation, the first sander 3 for receiving the wooden slats on the first dryer 2 and performing the first sanding operation on it, and the first sander 3 for receiving The second coating machine 4 for applying the wooden slats and performing the second coating operation on them, and the second dryer 5 for accepting the wooden slats on the second coating machine 4 and performing the second drying operation And the second sander 6 that is used to accept the wooden slats on the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com