Multi-station forming hydraulic machine for recombinant material

A multi-station, hydraulic press technology, applied in wood processing appliances, household appliances, and other household appliances, can solve the problems of not being able to provide large-tonnage, large-size, cost-effective mid-to-high-end heavy-duty heavy-duty equipment, small tonnage, etc., to achieve Strong system stability/fault tolerance, high automation efficiency, and improved production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

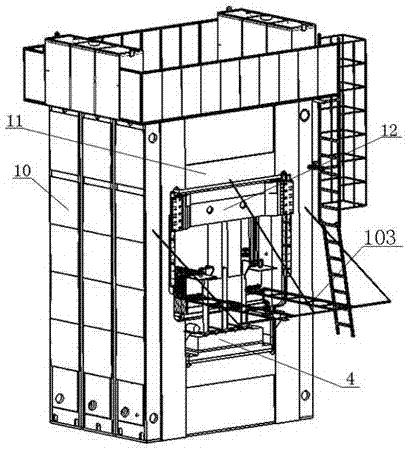

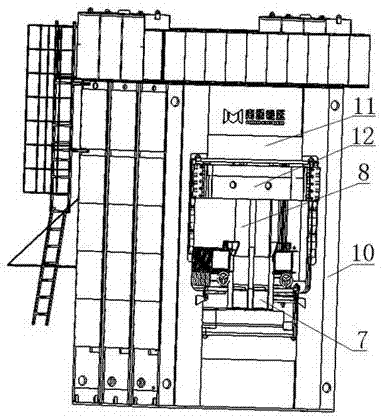

[0041] Refer to attached Figure 1-27 , a multi-station forming hydraulic machine for recombined wood, which includes a frame 10, an upper beam 11, a slider 12, a workbench 4, and a servo pressurized cylinder 5. The workbench 4 is installed at the lower end of the frame 10, and the upper beam 11 is installed at the upper end of the frame 10. The upper beam 11 is equipped with a servo pressurized cylinder 5, the lower end of the servo hydraulic cylinder 5 is connected to the slider 12, and the lower end of the slider 12 is equipped with a pressure head 8, and two clamping plates 6 are installed in parallel on the top of the workbench 4, between the two clamping plates 6 The lower end of the space is equipped with a U-shaped mold 7, the lower end of the pressure head 8 is located at the upper end between the two clamping templates 6, and the outer side of the clamping template 6 is sequentially equipped with a pin-threading device 1, a cloth pin device 2, and a pin-dropping devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com