Thruster flow passage structure, thruster and underwater vehicle

A propeller and flow channel technology, which is applied in the direction of ship propulsion, propulsion parts, ship parts, etc., can solve the problems of propeller thrust reduction, improvement, and unfavorable propulsion efficiency of propellers, so as to improve propulsion efficiency, reduce influence, and increase propulsion efficiency. The effect of high thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

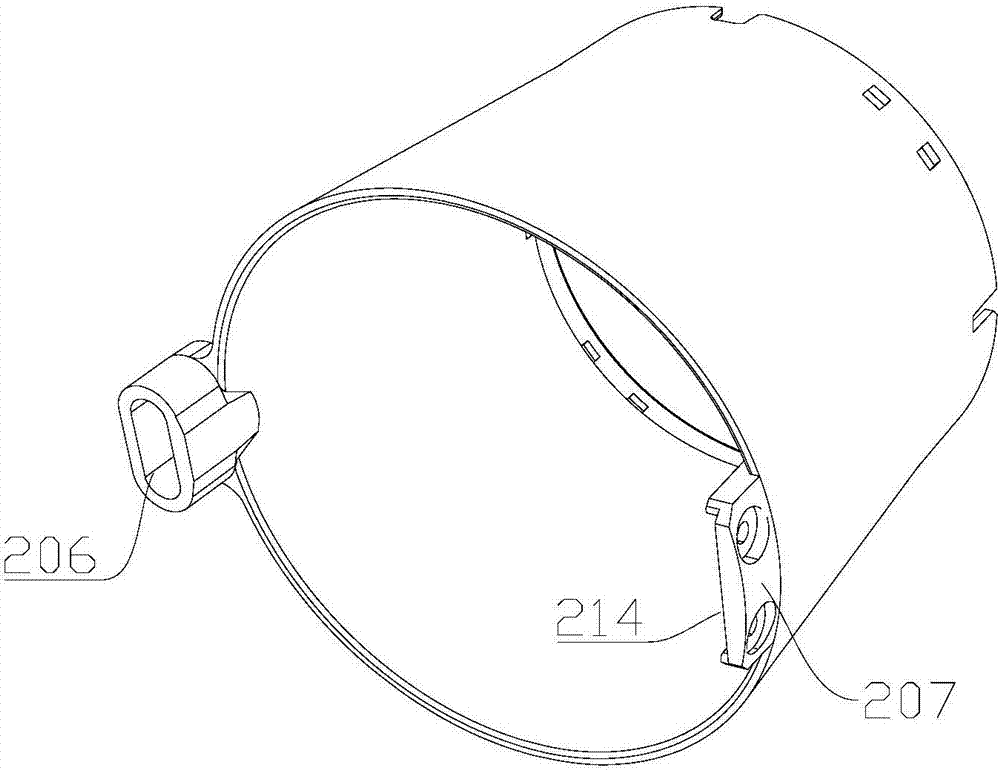

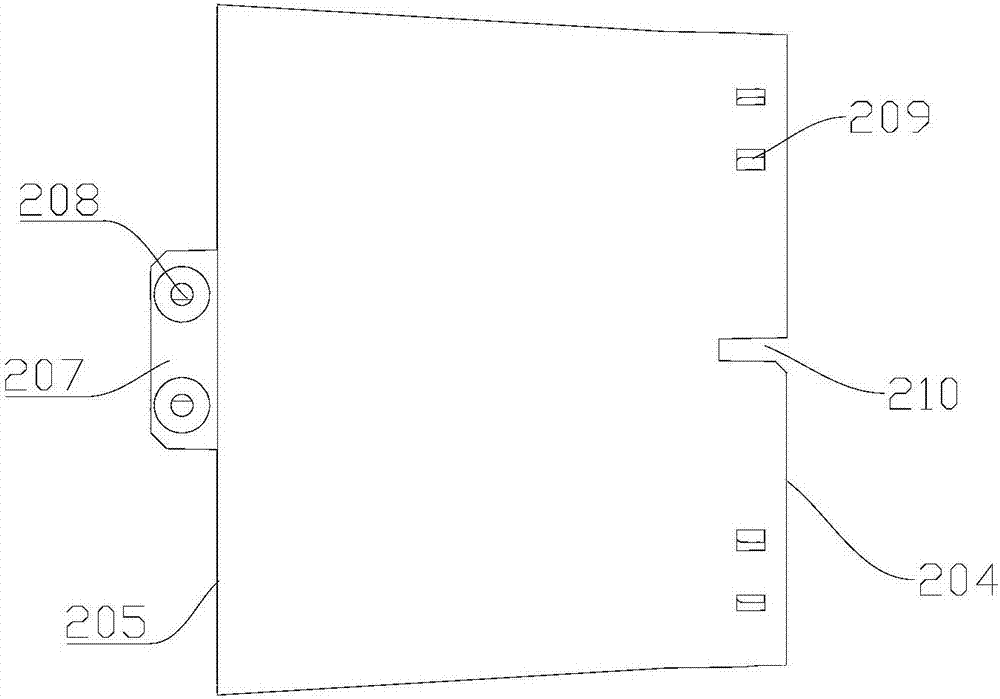

[0038] See Figure 1 to Figure 4 As shown, the first embodiment of the present invention provides a propeller flow channel structure, including a draft tube 203, the draft tube 203 has a front end 204 and a rear end 205 opposite, the radial cross section of the draft tube 203 is circular ; Along the axial direction of the draft tube 203, the outer diameter of the draft tube 203 gradually decreases from the rear end 205 to the front end 204; along the axial direction of the draft tube 203, the inner diameter of the draft tube 203 from the rear end 205 to The front end 204 first gradually decreases to the first set value, and then gradually increases from the first set value.

[0039] Specifically, the radial cross section of the draft tube 203 is a torus, and the projection of the axial cross section of the draft tube 203 on the reference plane has a trapezoidal outer profile, which ensures that the draft tube 203 has a very standardized fixed size , Reducing the processing diffic...

Embodiment 2

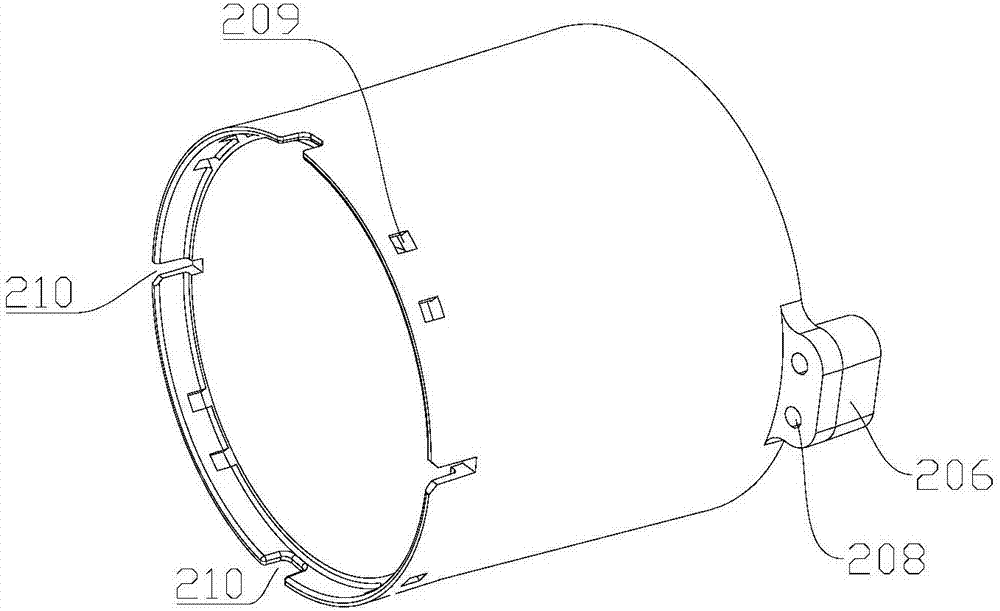

[0050] See Figure 5 to Figure 11 As shown, the second embodiment of the present invention provides a propeller, including a power unit 201, a propeller 202, and a propeller flow channel structure; the draft tube 203 is fixedly connected to the casing 211 of the power unit 201, and the power unit 201 is used for driving The propeller 202 rotates.

[0051] In an optional solution of this embodiment, the propeller further includes a stator blade structure, and the stator blade structure is fixedly connected to the flow channel structure of the propeller, that is, the stator blade structure is fixedly connected to the draft tube 203.

[0052] In an optional solution of this embodiment, the stator blade structure includes a mounting ring 101 and a plurality of stationary blades 102; the plurality of stationary blades 102 are fixedly connected to the inner wall of the mounting ring 101, and the plurality of stationary blades 102 are distributed radially, wherein the stationary blades O...

Embodiment 3

[0062] The embodiment of the present invention provides an underwater vehicle, including the propeller provided in the second embodiment and the aircraft fuselage. The propeller can be installed on the tail of the aircraft fuselage, on the head of the aircraft fuselage, or on both sides of the aircraft fuselage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com