A kind of automatic production line of PE plastic bottle cap and its production process

A technology of automated production lines and production processes, applied in sorting, storage devices, transportation and packaging, etc., can solve the problems of non-recycling of blank materials, poor quality of bottle cap products, low degree of automation, etc., to reduce the scrap rate, The effect of improving quality and increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

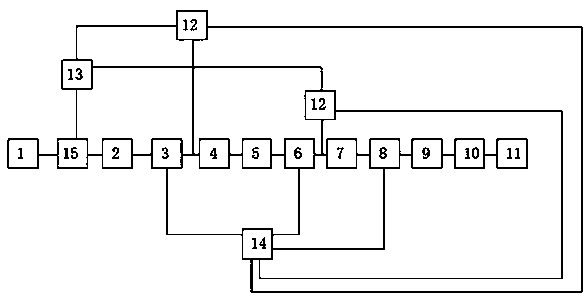

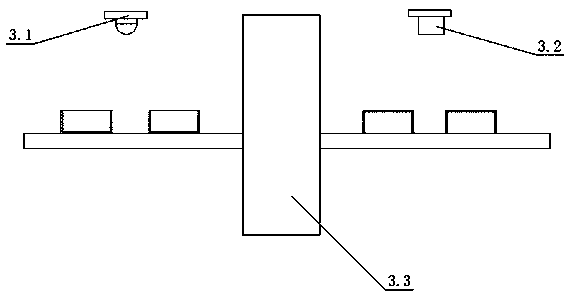

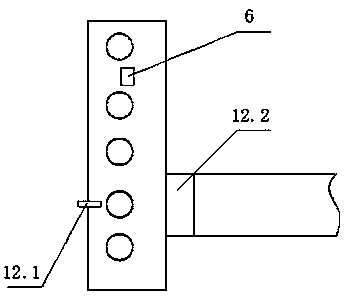

[0036] Such as figure 1 As shown, an automated production line for PE plastic bottle caps includes a vacuum suction machine 1, a mixing machine 15, an injection molding / compression molding machine 2, a blank imaging detection device 3, a ring cutting machine 4, and a first principle arranged in sequence. Capping machine 5, first imaging detection device 6, printing machine / film laminating machine 7, second imaging detection device 8, disinfection device 9, second cap unscrambling machine 10, packing equipment 11, control host 14 and crusher 13, all The vacuum suction machine 1, the mixing machine 15, the injection molding / compression molding machine 2, the blank imaging detection device 3, the ring cutting machine 4, the first cap unscrambl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com