Zinc-coated belt packaging and unloading device

A technology of unloading device and unloading mechanism, which is applied in the direction of transportation and packaging, thin material handling, winding strips, etc. It can solve the problems of easily crushed operators, easy to feel fatigue, high packaging cost, etc., and achieves easy unloading Material and transmission, structural design is scientific and reasonable, and the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

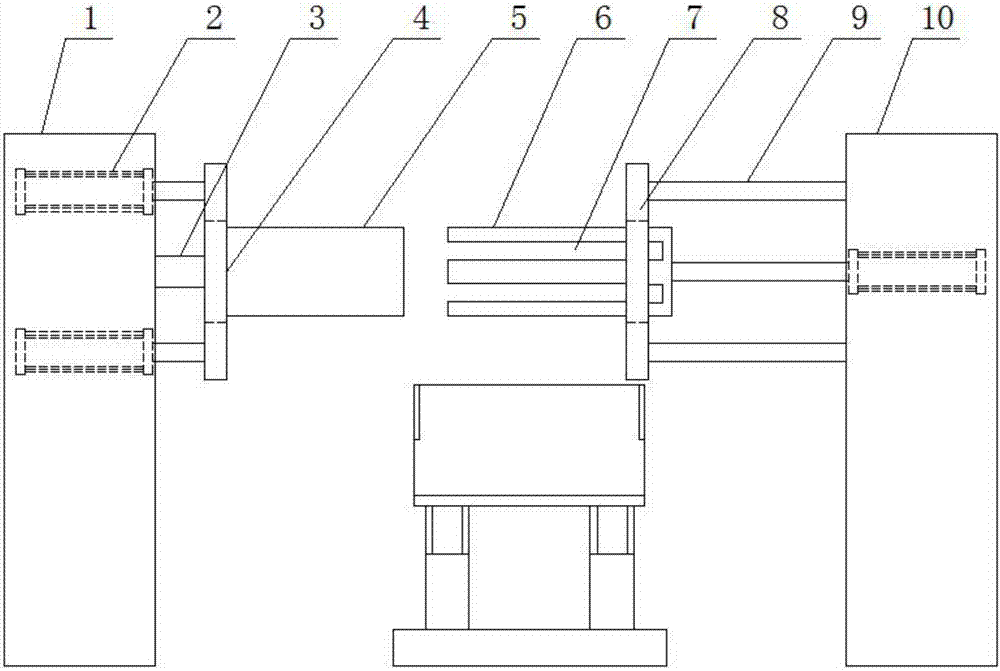

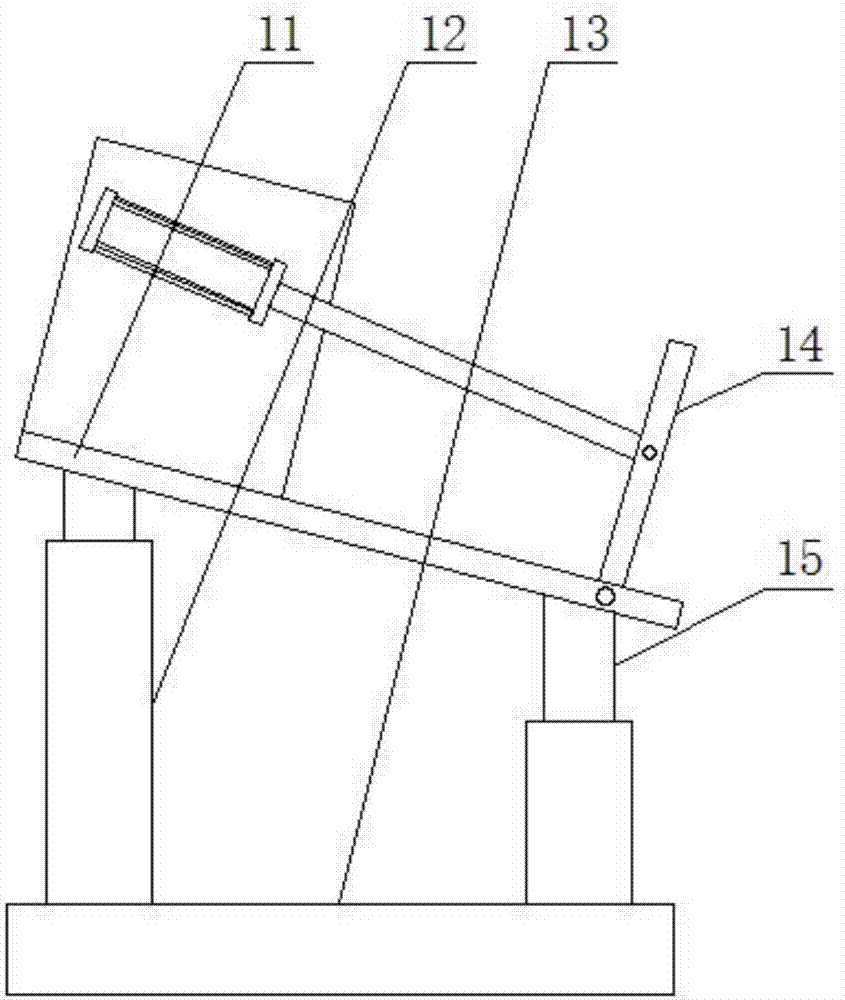

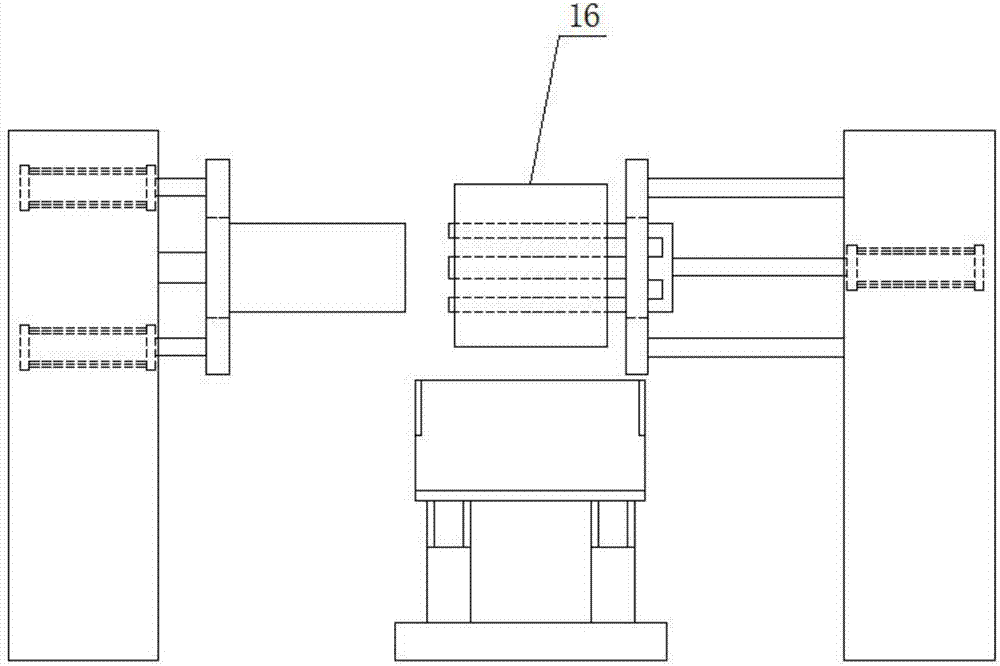

[0019] A galvanized strip packaging and unloading device, including a coil forming mechanism, and its innovation is that it also includes a packaging mechanism arranged opposite to the coil forming mechanism and an unloading mechanism arranged below the packaging mechanism. The mechanism is composed of a disk-forming frame 1, a motor, a cylinder 2, a collection shaft 5 and a push plate 4. A collection shaft driven by a motor drive shaft 3 is installed on the disk-forming frame, and a push plate is set on the collection shaft. Push plate is driven by the cylinder that is placed on the frame of forming a dish, and described packing mechanism is made of packing frame 10, packing frame 6, cylinder and baffle plate 8, on the described packing fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com