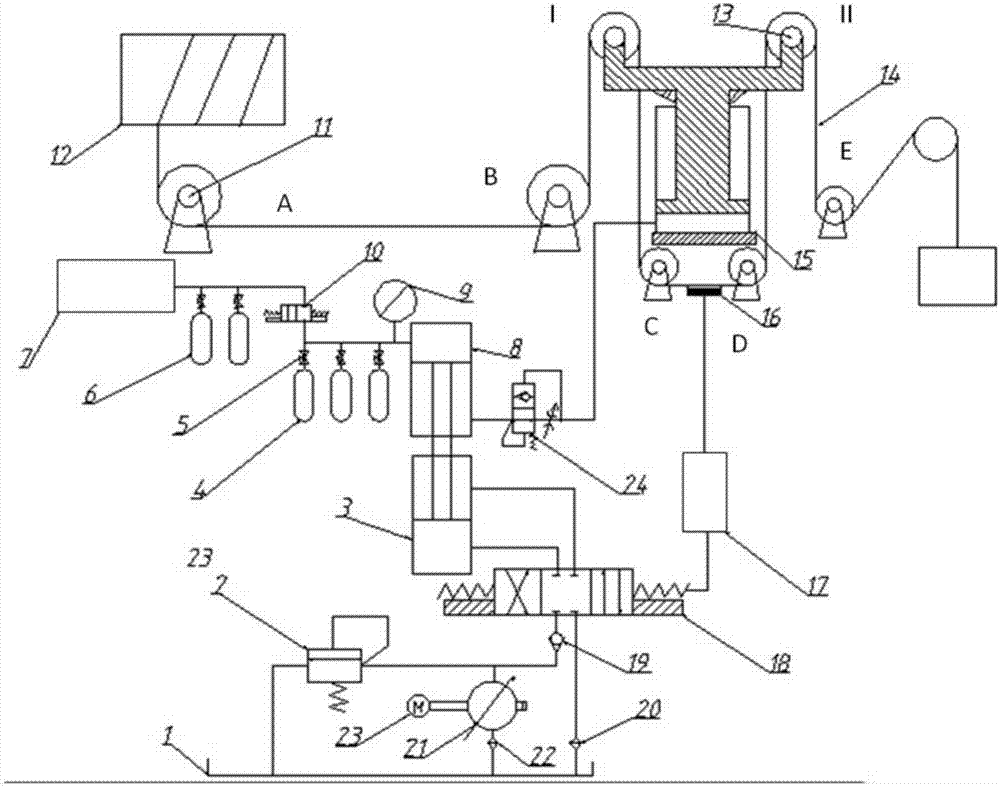

Hydraulic cylinder type semi-active heave compensation device for crane

A technology of heave compensation and active compensation, which is applied in the direction of fluid pressure actuators, hoisting devices, mechanical equipment, etc., and can solve the problems of complex active compensation, high energy consumption, small compensation range of hydraulic cylinders, and low compensation accuracy of passive compensation. , to achieve the effects of reducing cost and design difficulty, increasing compensation range, and simplifying hydraulic system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1: A 50-ton heavy object is hoisted on the sea, placed on a platform 1,500 meters underwater, and lowered at a constant speed of 0.5 meters per second. The cylinder material is No. 45 high-quality carbon steel, the diameter of the piston rod is 220mm, and the stroke of the piston rod is 160mm. The cast steel of model ZG310-570 is used as the material of the pulley, and the cast steel of model ZG270-500 is used as the material of the pulley frame.

[0044] In the hydraulic cylinder type semi-active heave compensation device of the crane in the present invention, when the mother ship rises, the compensation cylinder rises with the mother ship, the tension of the cable increases, and the rodless chamber of the compensation cylinder and the rodless chamber of the passive compensation cylinder are compressed , the rodless chamber of the passive compensation cylinder is connected with the working gas cylinder, the pressure of the rodless chamber of the passive compensa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com