Magnetic coagulation treatment device for mine water and process

A treatment device and mine water technology, applied in mining wastewater treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of high cost of magnetic seed recovery, low treatment efficiency, complex equipment, etc. The effect of small land area, high effluent water quality and fast settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

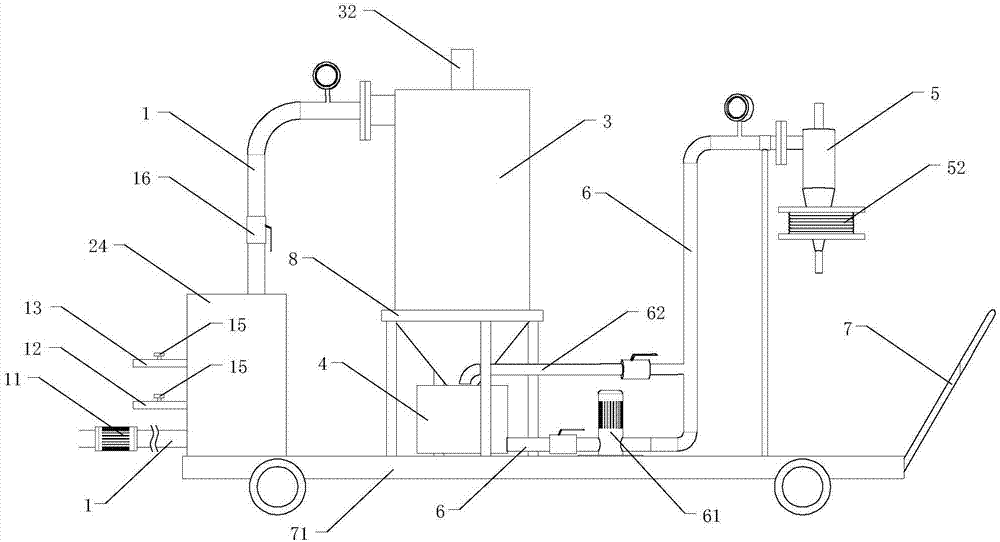

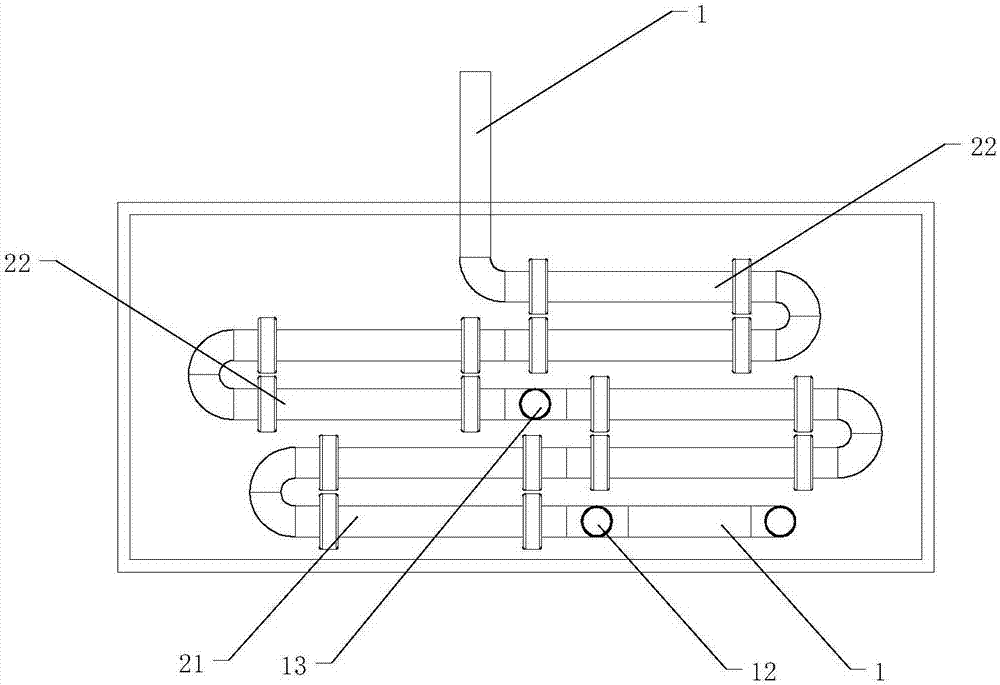

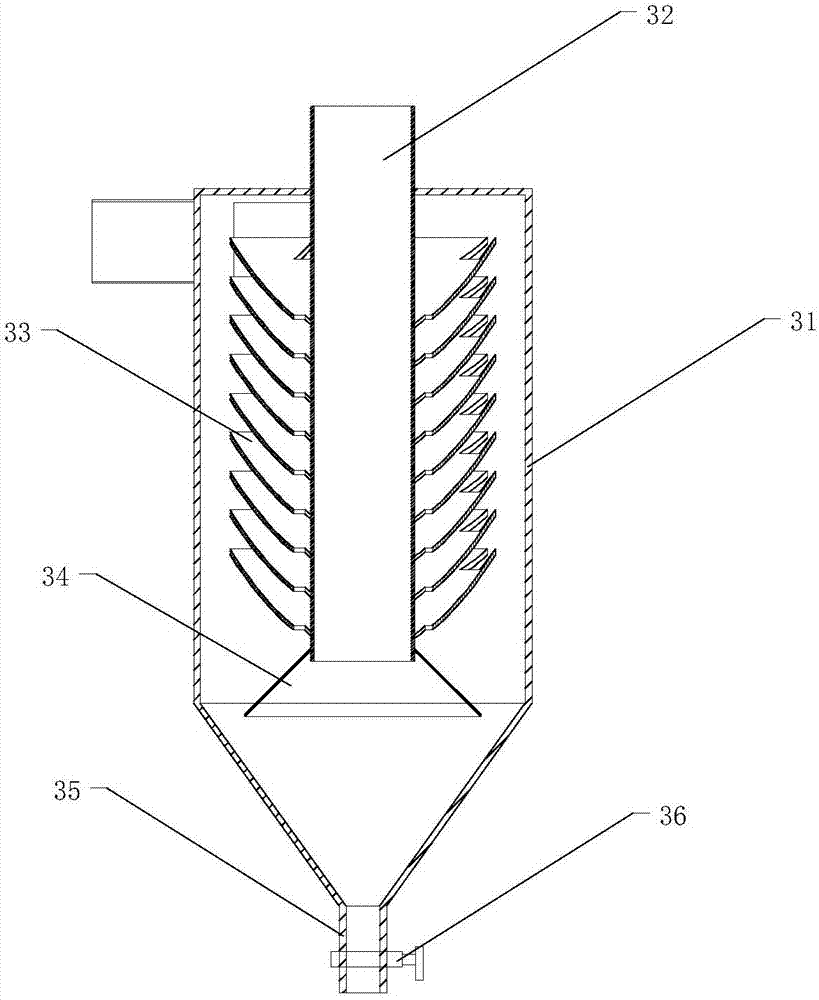

[0032] Embodiment 1, combining Figure 1 to Figure 5 , a mine water magnetic coagulation treatment device, comprising a main feed pipe 1, a mixer assembly 2 and a flocculation cyclone precipitator 3, the mixer assembly 2 includes a first mixer unit 21, a second mixer Unit 22, the above two mixer units are connected in the middle of the main feed pipe 2 in sequence. The first mixer unit 21 and the second mixer unit 22 are both composed of four static pipeline mixer units connected end to end in sequence. The part of the main feed pipe 1 near the first mixer unit 21 is its initial section, and the submersible pump 11 is installed on the initial section of the main feed pipe 1, and the part of the main feed pipe 1 near the second mixer unit 22 is its initial section. The end section, the end of the end section of the main feed pipe 1 , is in communication with the flocculation cyclone settler 3 . In use, the submersible pump 11 can pump mine water from the main feed pipe 1 thro...

Embodiment 2

[0042] Example 2, combined with Figure 1 to Figure 6 , a mine water treatment process, adopting the mine water magnetic coagulation treatment device, is characterized in that it includes the following steps: Step 1, open the submersible pump 11, and the mine water containing solid matter amount of 200mg / L is fed from the main feed pipe The water inlet of 1 enters, and the submersible pump 11 pumps the mine water into the mixer assembly 1. At the same time, the metering pump 15 arranged on the PAC feed pipe 12 is turned on, and the metering pump 15 on the PAC feed pipe 12 is adjusted according to the amount of PAC added. PAC is mixed with mine water at first, enters the first mixer unit 21 together, and fully mixes in the first mixer unit 21, and the concentration of PAC in mine water is controlled to be 50mg / L.

[0043] Open the metering pump 15 that is configured on the mixing feed pipe 13, the mixture of magnetic seeds and PAM enters the second mixer unit 22 through the mi...

Embodiment 3

[0046] Embodiment 3, combining Figure 1 to Figure 6 , a mine water treatment process, adopting the mine water magnetic coagulation treatment device, is characterized in that it includes the following steps: Step 1, open the submersible pump 11, and the mine water containing solid matter amount of 250mg / L is fed from the main feed pipe The water inlet of 1 enters, and the submersible pump 11 pumps the mine water into the mixer assembly 1. At the same time, the metering pump 15 arranged on the PAC feed pipe 12 is turned on, and the metering pump 15 on the PAC feed pipe 12 is adjusted according to the amount of PAC added. PAC is first mixed with mine water, enters the first mixer unit 21 together, and is fully mixed in the first mixer unit 21, and the concentration of PAC in the mine water is controlled at 55mg / L.

[0047] Open the metering pump 15 that is configured on the mixing feed pipe 13, the mixture of magnetic seeds and PAM enters the second mixer unit 22 through the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com