Concrete, and formula and preparation method thereof

A technology for concrete and formula, applied in the field of concrete, can solve the problems that the mechanical strength of concrete cannot meet the technical requirements and the high manufacturing cost, and achieve the effects of simple and easy preparation process, cost reduction, and enhancement of thermal insulation and sound insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

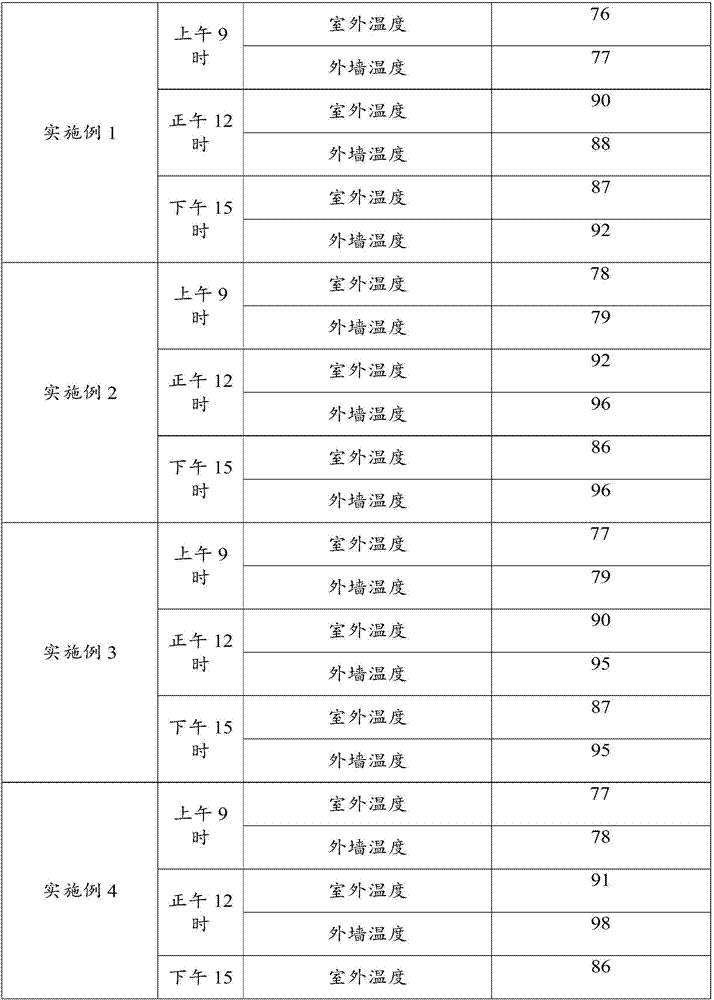

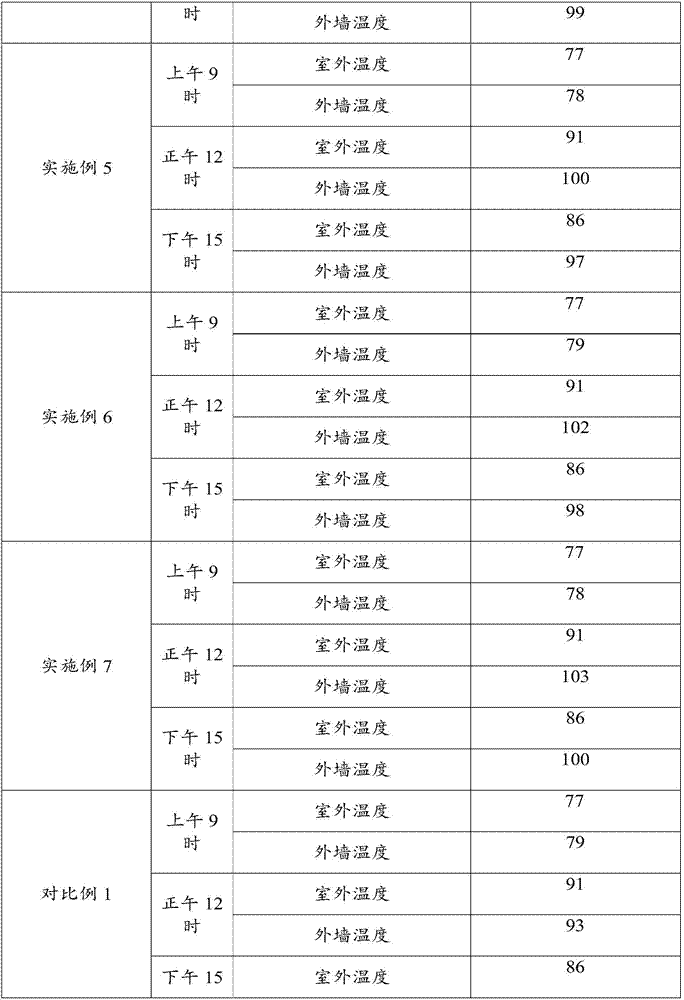

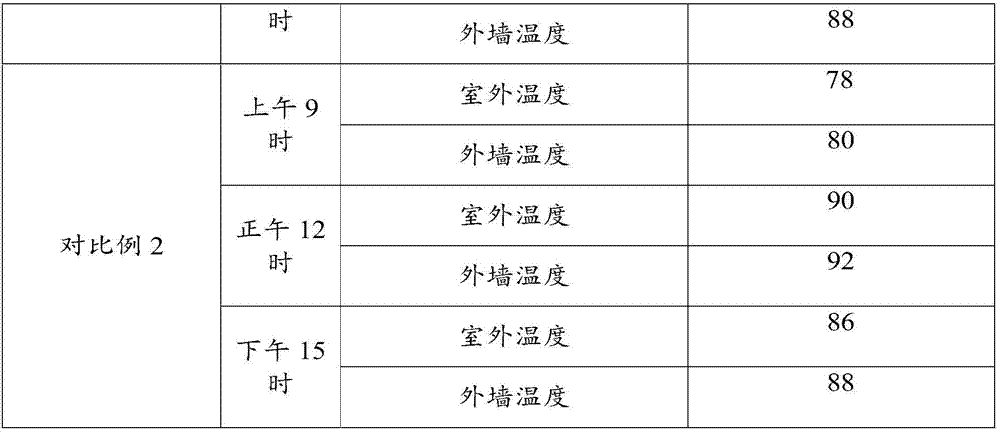

Examples

preparation example Construction

[0026] The embodiment of the present invention also provides a kind of preparation technology of concrete, comprises the following steps:

[0027] S1. Mix 5-20 parts of hollow glass microspheres and 3-15 parts of polypropylene fibers at a temperature of 50-70° C. to obtain a first mixed powder.

[0028] First mix the functional material composed of hollow glass microspheres and polypropylene fibers at a higher temperature, so that the polypropylene fibers can be coated on the surface of the hollow glass microspheres, increasing the intermolecular force and effectively reducing the size of the hollow glass. The distance between the microbead molecules enhances its thermal insulation and sound insulation effect. The mixing process needs to be controlled within a certain range. If the temperature is too low, it is not conducive to ensuring the uniformity of mixing. If the temperature is too high, it will easily cause side reactions between raw materials and affect the effect of h...

Embodiment 1

[0034] The present embodiment provides a kind of preparation technology of concrete, and it comprises the following steps:

[0035] Mix 5 parts of hollow glass microspheres and 3 parts of polypropylene fiber at a temperature of 50°C to obtain the first mixed powder; mix 30 parts of metamorphic marble powder, 20 parts of cement, 15 parts of sand, 2 parts of water and the first Blend the powders to mix.

[0036] This embodiment provides a concrete, which is prepared by the above concrete preparation process.

Embodiment 2

[0038] The present embodiment provides a kind of preparation technology of concrete, and it comprises the following steps:

[0039] Mix 20 parts of hollow glass microspheres and 15 parts of polypropylene fiber at a temperature of 70°C to obtain the first mixed powder; mix 60 parts of metamorphic marble powder, 50 parts of cement, 35 parts of sand, 10 parts of water, 2 parts Lignosulfonate (water reducing agent), 3 parts of water-resistant blending powder and the first mixed powder are mixed. Among them, the water-resistant blending powder includes 2.25 parts of water-resistant rubber powder and 0.75 parts of polyurethane.

[0040] This embodiment provides a concrete, which is prepared by the above concrete preparation process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com