High-energy pressure-loaded and insensitive booster explosive and preparation method

A booster, sensitive technology, applied in explosives, offensive equipment, non-explosive/non-thermal agent components, etc., can solve the problem of detonation output capacity decline, etc., to meet the requirements of slow roasting, simple process and high energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

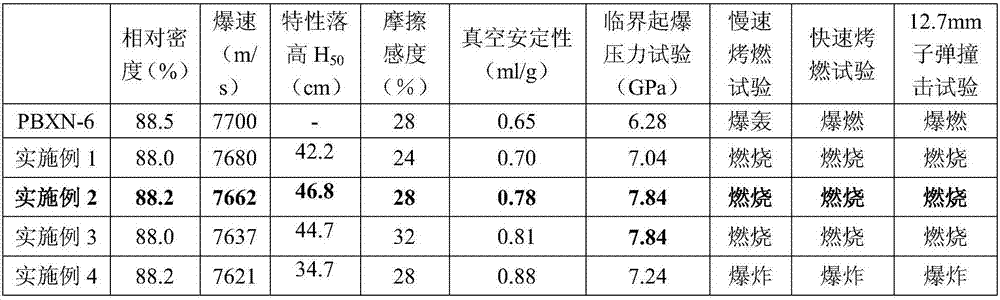

Examples

Embodiment 1

[0011] This embodiment is carried out with reference to the following mass percentage composition: 98% mixed crystal (68.6% FOX-7, 29.4% RDX) and 2% butyl acrylate-acrylonitrile copolymer emulsion.

[0012] Preparation of this example: Take the preparation of 1000g of explosives as an example, weigh 980g of mixed crystal material and put it into 2000ml of water, weigh the emulsion and pour it into water, stir for 5-10 minutes to form a suspension, and prepare anhydrous sulfuric acid with a concentration of 10%. Sodium solution, add water after it is completely dissolved, add a small amount of ethyl acetate, heat up to 55°C-60°C, stir for 0.5 hours, discharge, rinse with 20°C water repeatedly three times, and pass through a 10-mesh sieve at the same time; The booster powder granules are placed in an oven at a temperature of 60° C. to 65° C. for 5 hours, and the booster powder is obtained after discharging. Accurately weighed and pressed into shape by the constant volume method,...

Embodiment 2

[0014] This embodiment is carried out with reference to the following mass percentage composition: 98% mixed crystal (63.6% FOX-7, 34.4% RDX) and 2% butyl acrylate-acrylonitrile copolymer emulsion. The preparation method of this embodiment refers to embodiment 1.

Embodiment 3

[0016] This embodiment is carried out with reference to the following mass percentage composition: 98% mixed crystal (58.6% FOX-7, 39.4% RDX) and 2% butyl acrylate-acrylonitrile copolymer emulsion. The preparation method of this embodiment refers to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com