A kind of vulcanization method of adsorbent

An adsorbent and sulfidation treatment technology, applied in the petroleum industry, refined hydrocarbon oil, etc., can solve the problems of slow measurement process, difficult to meet industrial needs, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

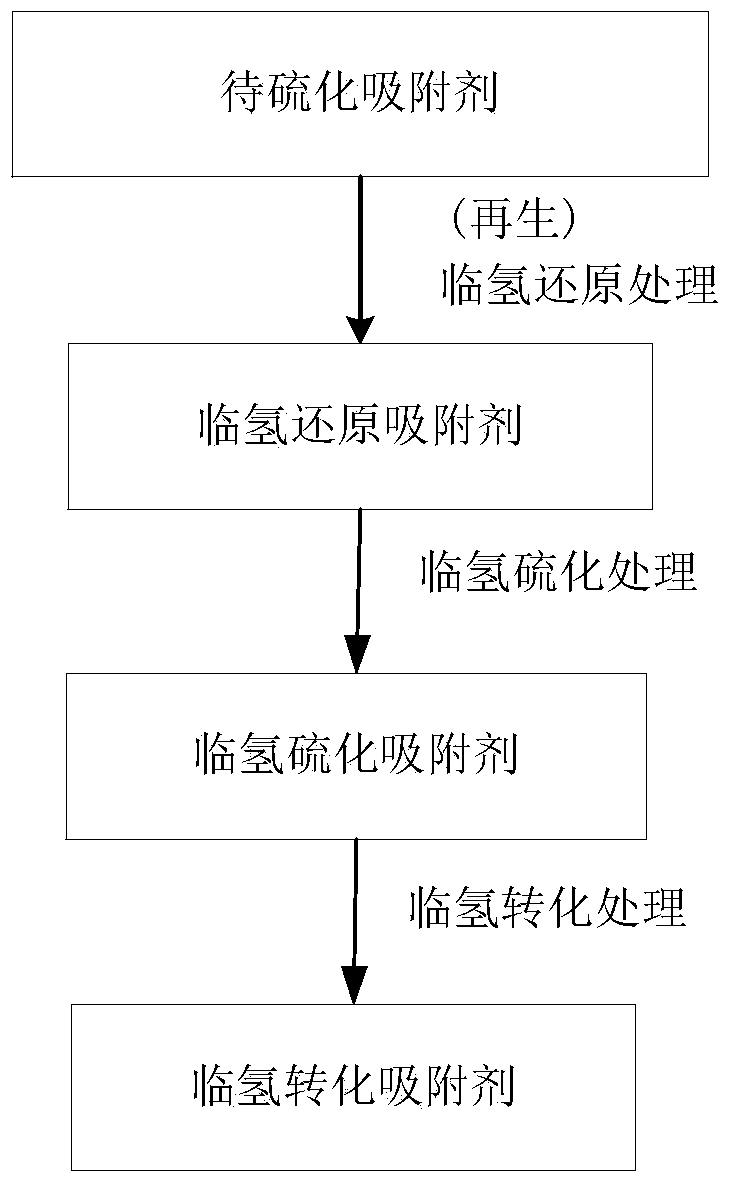

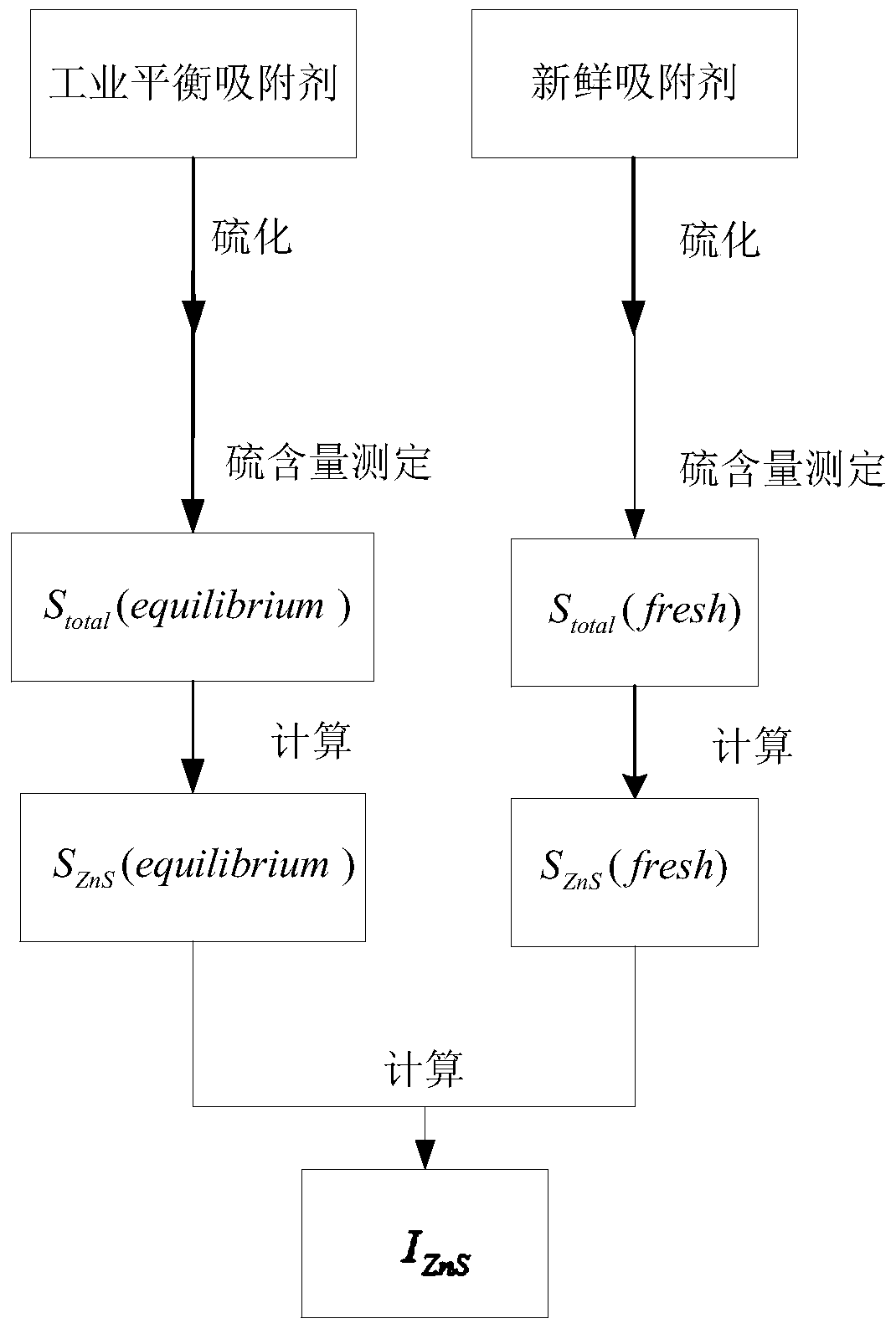

Method used

Image

Examples

Embodiment 1

[0052] Put 2g of FCAS-R09 fresh adsorbent in a small fixed-bed reactor, and firstly treat the fresh adsorbent under the conditions of pressure 2.5 MPa, hydrogen (hydrogen reduction gas, the same below) 16L / h and a temperature of 400°C. Hydrogen reduction treatment was performed for 2 hours to obtain the hydrogen reduction adsorbent.

[0053] Using CS with a mass fraction of sulfur of 1% 2 Cyclohexane solution is used as the sulfur-containing material, and when the reaction pressure is 2.5 MPa, the hydrogen gas (hydrogen sulfide gas, the same below) is 16L / h, and the weight hourly space velocity of the sulfur-containing material is 5h -1 1. Under the reaction condition of 300° C., the hydrogen-reducing adsorbent was hydrosulfurized for 4 hours to obtain the hydrogen-sulfide adsorbent.

[0054] After the hydrosulfide treatment, the hydrosulfide adsorbent obtained was subjected to hydrogen conversion treatment at 350° C. for 2 h in a 16 L / h hydrogen gas (hydrogen conversion gas,...

Embodiment 2

[0058] Put 2g of industrial equilibrium adsorbent S1 in a small fixed-bed reactor, first roast and regenerate industrial equilibrium adsorbent S1, the regeneration conditions are: regeneration stage 1, regeneration temperature is 430°C, pressure is normal pressure, regeneration gas is air Mixed gas with nitrogen (8L / h air + 8L / h nitrogen), regeneration for 2h; regeneration stage 2, regeneration temperature is 480°C, pressure is 0.1 MPa, regeneration gas is a mixture of air and nitrogen (12L / h air +4L / h nitrogen), regeneration for 2h; regeneration stage 3, regeneration temperature is 530°C, pressure is 0.1MPa, regeneration gas is 16L / h air, regeneration is 2h.

[0059] The regenerated industrial equilibrium adsorbent S1 was subjected to hydrogen reduction treatment for 0.5h under the conditions of pressure 2.5 MPa, hydrogen gas 16L / h, and temperature 300°C to obtain hydrogen reduction adsorbent S1.

[0060] Then use CS with 1% sulfur mass fraction 2 The cyclohexane solution of...

Embodiment 3

[0065] Put 2g of industrial equilibrium adsorbent S2 in a small fixed-bed reactor, and first roast and regenerate industrial equilibrium adsorbent S2. The regeneration conditions are: regeneration stage 1, regeneration temperature is 430 ° C, pressure is 0.5 MPa, and regeneration gas is Mixed gas of air and nitrogen (8L / h air + 8L / h nitrogen), regeneration 2h; regeneration stage 2, regeneration temperature is 480 ° C, pressure is 0.5 MPa, regeneration gas is a mixed gas of air and nitrogen (12L / h Air + 4L / h nitrogen), regeneration for 2h; regeneration stage 3, regeneration temperature is 530°C, pressure is 0.5MPa, regeneration gas is 16L / h air, regeneration is 2h.

[0066] The regenerated industrial equilibrium adsorbent S2 was subjected to hydrogen reduction treatment for 2 hours under the conditions of pressure 1.5 MPa, hydrogen gas 32L / h, and temperature 400°C to obtain hydrogen reduction adsorbent S2.

[0067] Then use the reformed gasoline solution of dimethyl disulfide w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com