Spot welding quality real-time ultrasonic non-destructive testing device and method

A non-destructive testing and ultrasonic technology, applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, welding equipment, resistance welding equipment, etc., can solve problems such as ultrasonic probe positioning errors, avoid positioning errors, improve adaptability, and strong reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

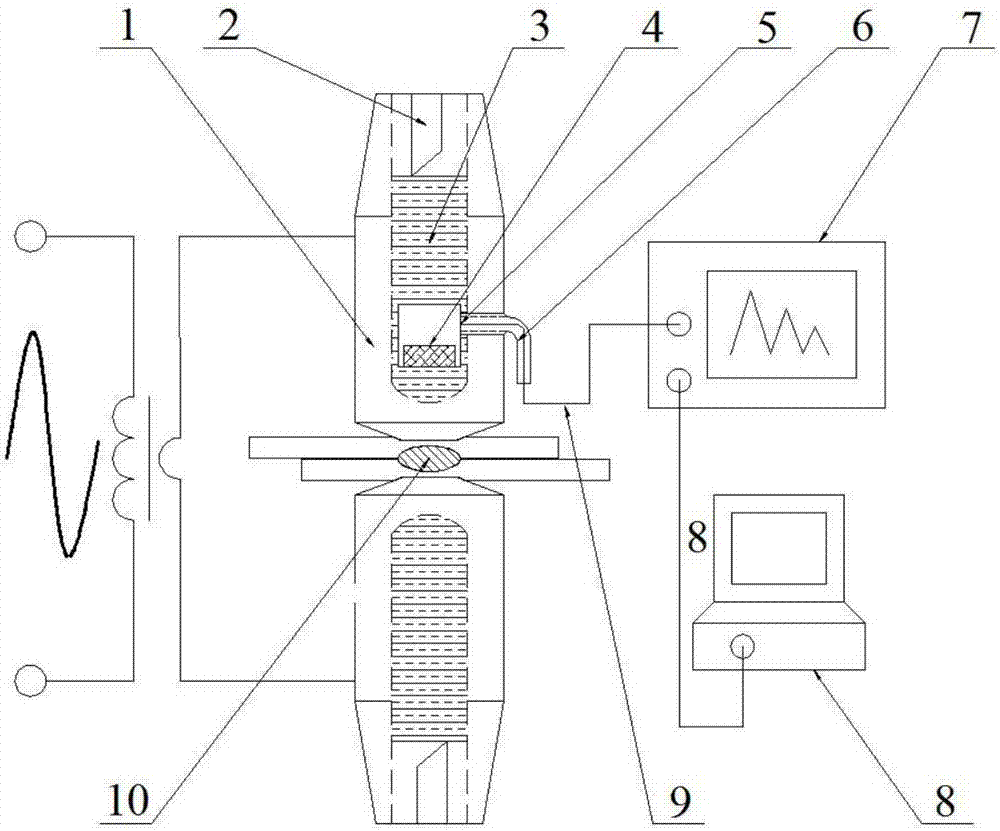

[0024] Such as figure 1 As shown, the spot welding quality real-time ultrasonic nondestructive testing device of the present invention includes an ultrasonic probe 4 , an ultrasonic detector 7 , a computer 8 , a spot welding machine and a spot welding electrode 1 . The ultrasonic probe is connected with the ultrasonic detector 7 , and the ultrasonic detector 7 is connected with the computer 8 .

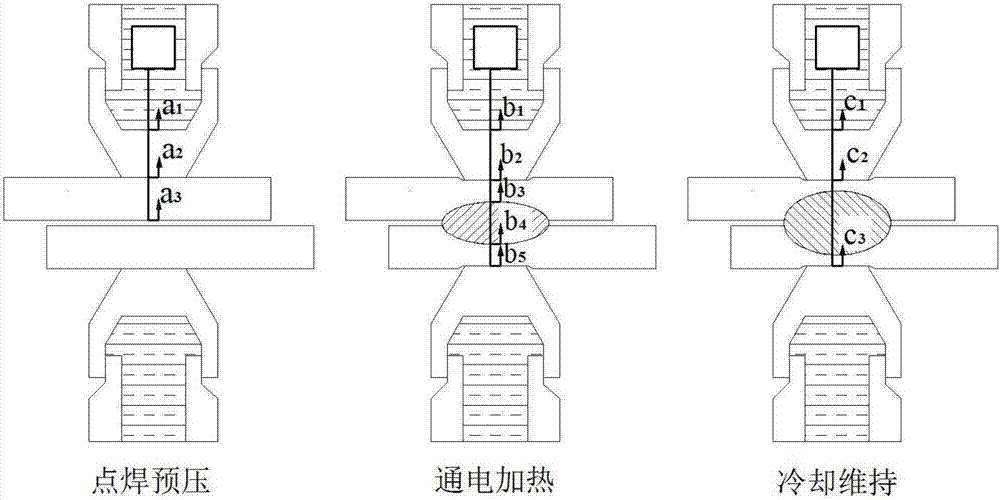

[0025] The ultrasonic probe 4 has the functions of transmitting and receiving ultrasonic signals at the same time. The ultrasonic probe 4 is embedded in the spot welding electrode 1 , and the spot welding electrode 1 is provided with a cavity for accommodating cooling water 3 . The ultrasonic probe 4 is placed in the cavity, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com