Flexible touch control mother board, manufacturing method thereof, flexible touch control board and touch control panel

A flexible touch and motherboard technology, applied in the field of flexible touch substrate, flexible touch motherboard and its preparation, and touch panel, to avoid bad bubbles, reduce stress concentration, and improve product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

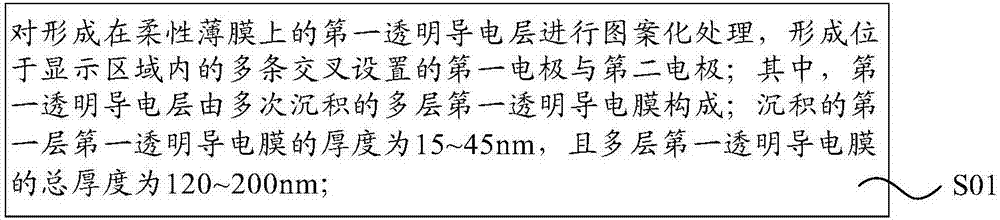

[0037] The embodiment of the present invention provides a method for preparing a flexible touch mother board, such as figure 2 As shown, the preparation method includes:

[0038] Step S01: Perform a patterning process on the first transparent conductive layer formed on the flexible film to form a plurality of intersecting first electrodes and second electrodes in the display area; wherein the first transparent conductive layer is deposited multiple times The thickness of the first transparent conductive film deposited is 15-45nm, and the total thickness of the first transparent conductive film is 120-200nm.

[0039] It should be noted that, first, the above-mentioned flexible touch mother board provided by the embodiment of the present invention includes a plurality of display areas, which can be divided into multiple small pieces, that is, a single flexible touch substrate is formed. Each touch substrate includes a display area, so that mass production of flexible touch substrates...

Embodiment 2

[0088] Further, an embodiment of the present invention also provides a flexible touch mother board, which is made by the above-mentioned preparation method. It can obtain a relatively flat surface while having a lower electrode channel impedance, and is the first in the industry to realize the Roll to Sheet low square resistance process.

Embodiment 3

[0090] Further, an embodiment of the present invention also provides a flexible touch substrate, which is any one of a plurality of sub-substrates cut from the above-mentioned flexible touch mother board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com