Brushless doubly-fed machine torque ripple minimization control device and control method thereof

A technology of torque ripple and doubly-fed motors, which is applied in the direction of torque ripple control, motor generator control, and control of electromechanical transmission devices, etc. It can solve system performance deterioration, increase the complexity of the control system, and complicate the formulation of fuzzy control rules, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below with reference to the accompanying drawings and examples.

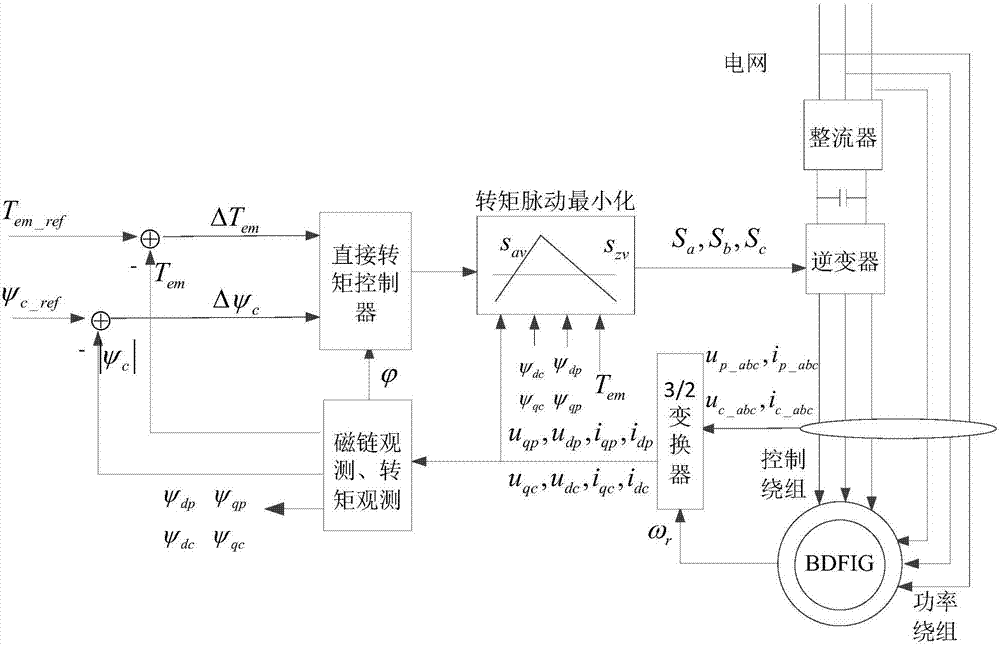

[0074] Such as figure 1 As shown, a brushless doubly-fed motor torque ripple minimization control device consists of a 3 / 2 coordinate converter, a flux linkage and torque observer, a torque comparator, a flux linkage comparator, a direct torque control unit, Composed of torque ripple minimization control unit, incremental encoder, DC power supply, inverter and brushless double-fed motor;

[0075] The 3 / 2 coordinate converter realizes three-phase / two-phase coordinate transformation, and obtains the voltage and current of the control winding and the power winding in the rotor speed coordinate system;

[0076] The flux linkage and torque observer is used to calculate flux linkage, torque, and control winding flux linkage angle;

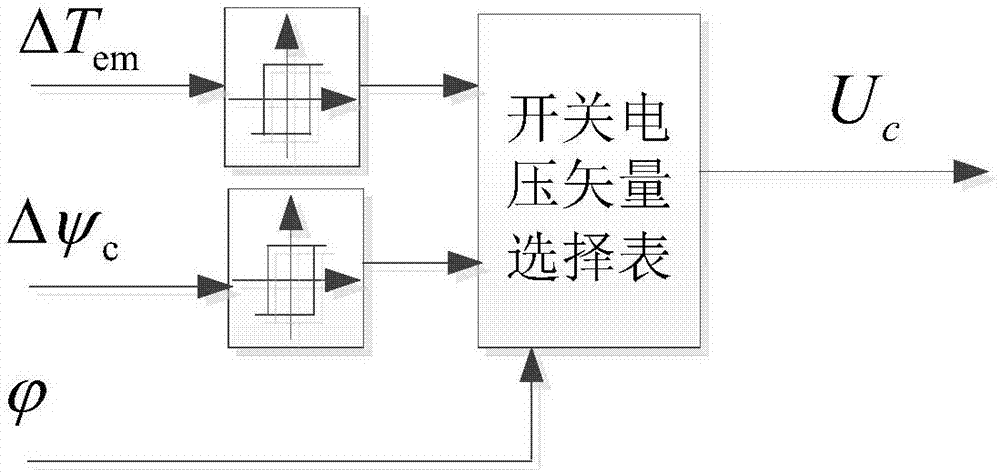

[0077] The flux linkage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com