Base plate-free concrete floating platform capable of realizing one-time pouring molding and modularized splicing

A technology without bottom plate and concrete, used in floating bridges, floating buildings, bridge forms, etc., can solve the problems of lack of aesthetics, poor weather resistance, low structural strength, etc., to simplify the production process, improve the structural continuity, and reduce the difficulty of production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

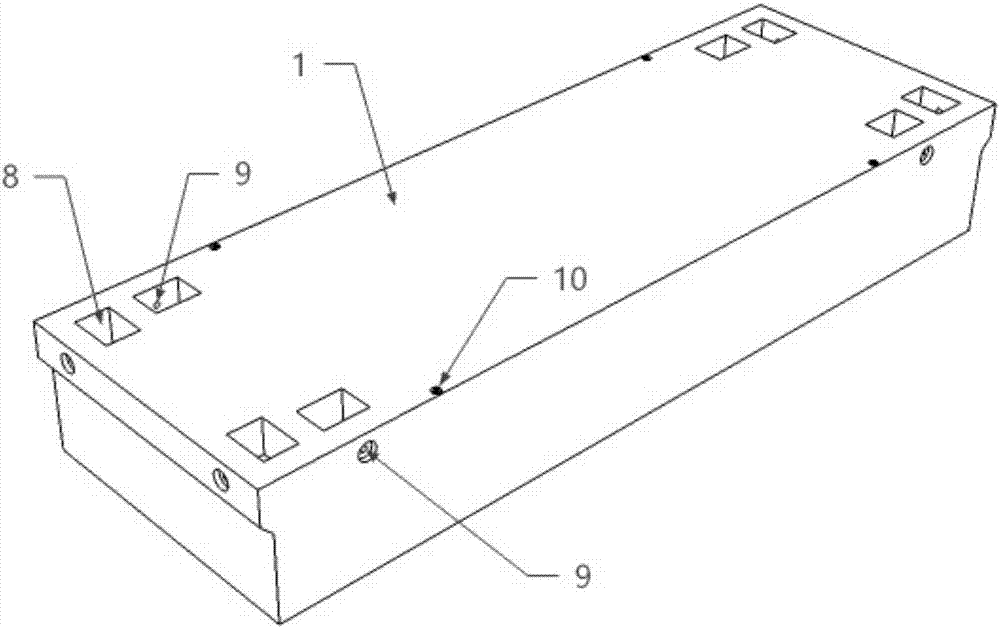

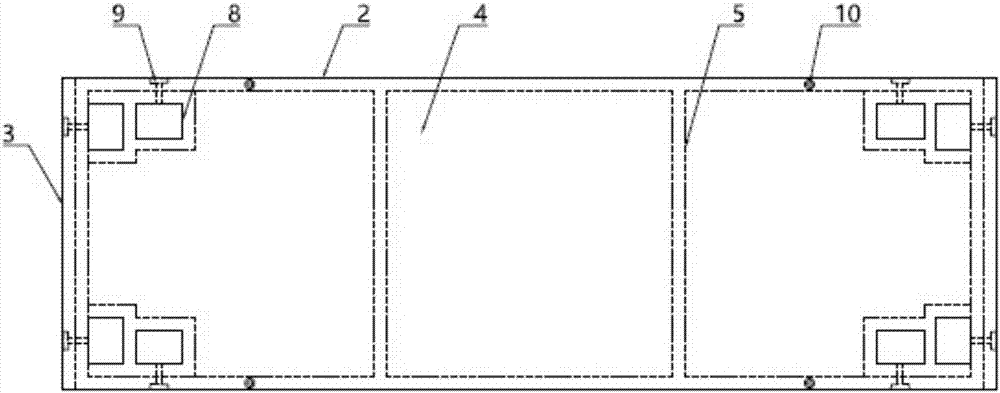

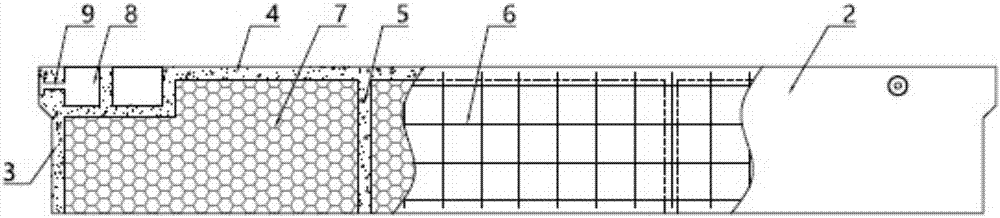

[0033] like Figure 1-3As shown, the concrete floating platform without a bottom plate that can be poured into a modular joint in this embodiment includes a box-shaped floating platform body 1 without a bottom plate. The floating platform body 1 includes a flat side plate 2 and a raised side plate. 3. The top plate 4 and the inner partition 5, wherein the side plates on both sides in the longitudinal direction are raised side plates 3, and the upper end of the raised side plate 3 is provided with a raised portion protruding longitudinally along the floating platform body 1, and the The top surface of the raised portion is level with the top surface of the top plate 4, and the raised side plate 3 is designed to prevent the floating platform body 1 from colliding with the adjacent floating platform when there is relative undulating motion in the wave environment after splicing; The side plate is a flat side plate 2, and the inner partition 5 is arranged inside the floating platf...

Embodiment 2

[0036] like Figure 4-6 As shown, a plurality of floating platform bodies 1 are arranged in a matrix and spliced together to form a longer floating bridge or a larger platform, and two adjacent floating platform bodies 1 are connected by connecting components; the floating platform Both the flat side plate 2 and the raised side plate 3 of the body 1 are provided with connection holes 9 for installing the connection assembly; The flexible connecting rod 11 includes two studs 12 and a steel strand 13 connected between the two studs 12; the stud 12 and the steel strand 13 are connected by welding; the flexible connecting rod 11 is used to connect the floating platform Relative ups and downs between, adapt to the wave environment, high seakeeping, Figure 6 In the illustrated embodiment, four floating platform bodies 1 are interconnected. The floating platform body 1 uses 8 sets of flexible connection assemblies. If there are relatively large waves in the water area where the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com