Method for removing foreign matter on roller surfaces in hot galvanizing horizontal type annealing furnace

A horizontal annealing furnace and foreign matter removal technology, which is applied to heat treatment furnaces, furnaces, furnace types, etc., can solve the problems of unit production impact, tension partition control cannot be realized, and horizontal furnaces cannot be applied, so as to ensure product quality and reduce Production cost, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

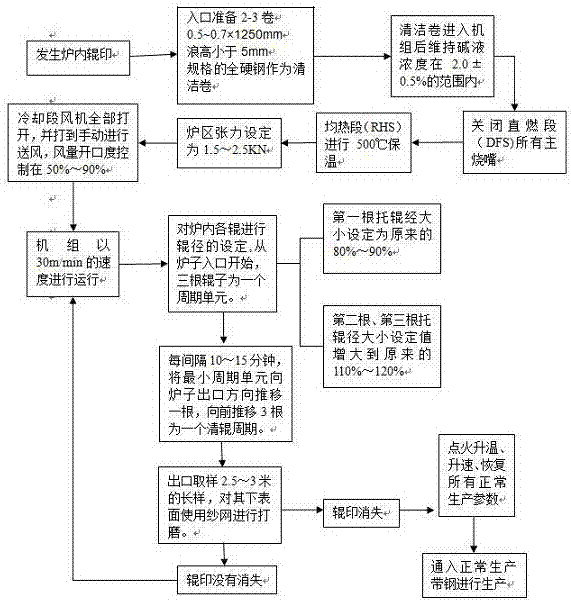

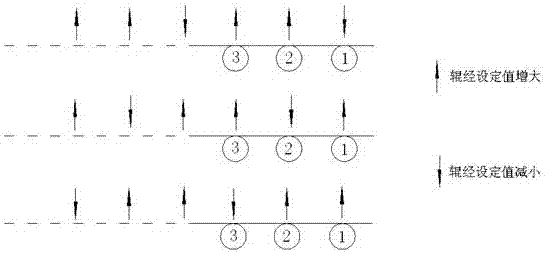

[0015] Example 1: A method for removing foreign matter on the roller surface of a hot-dip galvanizing horizontal annealing furnace, the method is as follows: 1) The thickness of the entrance is 0.5-0.7mm, and the width is the widest width required by the process. The product is 2-3 rolls, The steel type is hard steel with hard steel as the strip steel for cleaning and ready to be passed into the unit; by selecting the strip steel of appropriate specifications, the best cleaning effect can be achieved during the friction process between the strip steel and the idler rollers in the furnace;

[0016] 2) The strip is cleaned with 2±0.5% lye, electrolytically cleaned, rinsed with hot water, and dried with hot air ≥ 120°C to clean the surface of the strip to ensure that it enters the furnace surface clean and free of foreign matter; The concentration directly determines the cleaning effect, but too high concentration of lye will cause the lye itself to remain on the surface of the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com