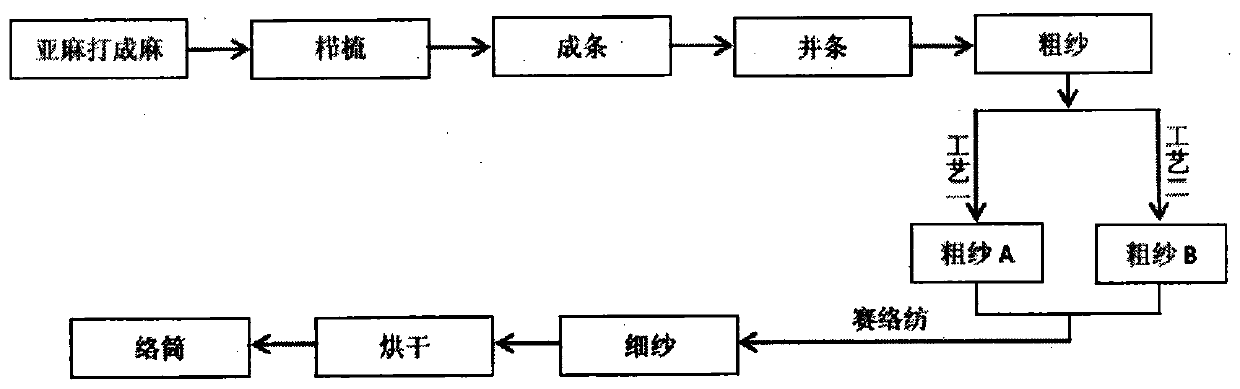

A preparation method of flax semi-bleached yarn with dyeing differentiation

A differentiated flax technology, applied in the textile industry, can solve problems such as long hairiness of spun yarns, difficulty in merging and drafting, loss of yarn strength, etc., and achieve strong market competitiveness, unique fabric style, and strong weaving selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] After the flax raw material is combed by a combing machine, it is drawn and combined on the forming and drawing equipment, and then the roving with a fineness of 2.6Nm and a twist of 31T / m is spun on the roving equipment, and then the rovings are placed separately for boiling and bleaching In the equipment, two chemical processes are carried out:

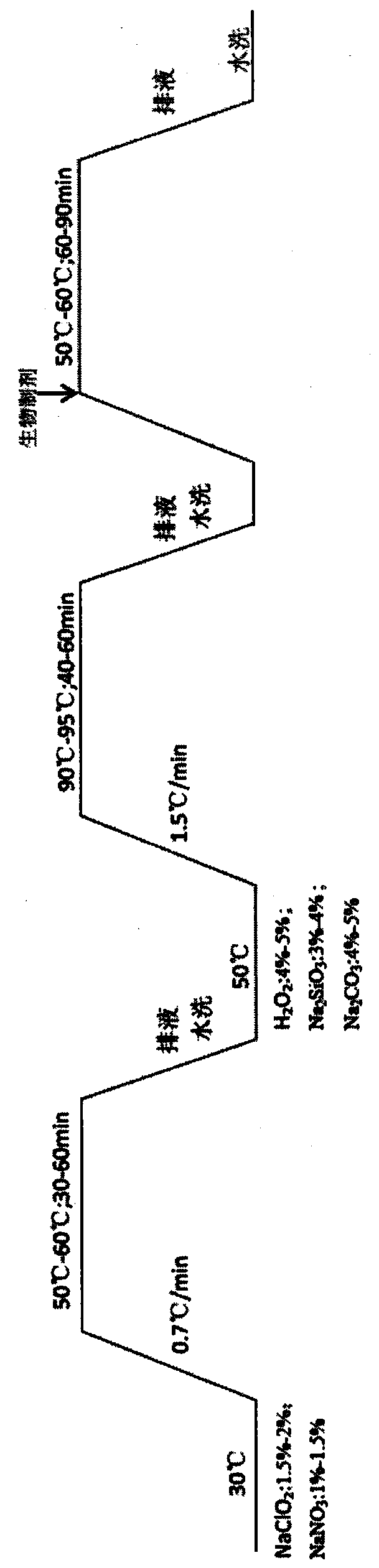

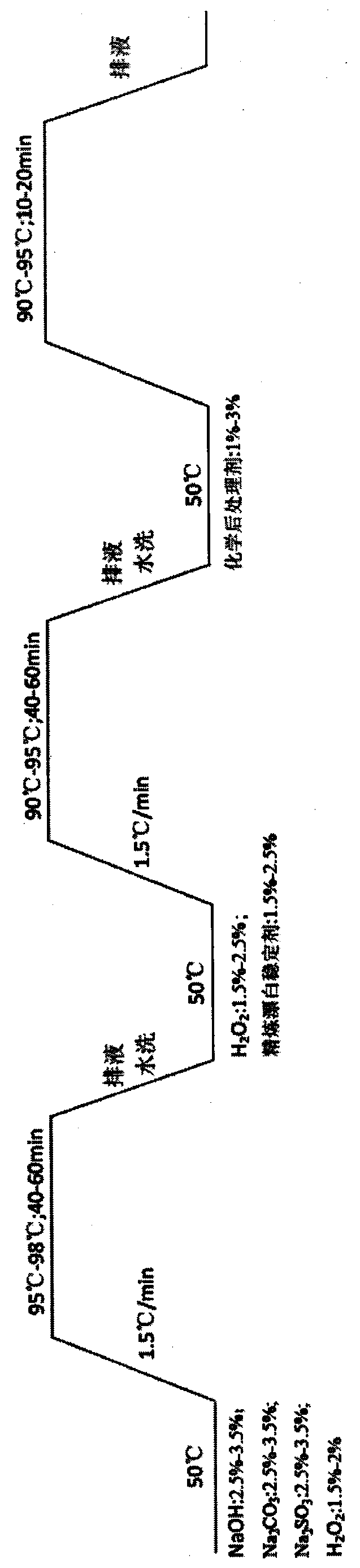

[0035] Chemical treatment process A is divided into three steps: sub-bleaching, oxygen bleaching, and biological post-treatment:

[0036] Add 1.5% (owf) sodium chlorite and 1% (owf) sodium nitrate during the sub-bleaching process, the pH value is controlled at 2.5, the initial temperature is 30°C, the temperature rises to 50°C, the heating rate is 0.7°C / min, the holding time After 30 minutes, the heat preservation is completed and the drainage liquid is washed to neutral to complete the sub-bleaching; then carry out oxygen bleaching, add 5% (owf) hydrogen peroxide, 4% (owf) sodium silicate, 5% (owf) soda ash, and control the ...

Embodiment 2

[0042] After the flax raw material is combed by a combing machine, it is drawn and combined on the forming and drawing equipment, and then the roving with a fineness of 2.6Nm and a twist of 31T / m is spun on the roving equipment, and then the rovings are placed separately for boiling and bleaching In the equipment, two chemical processes are carried out:

[0043] Chemical treatment process A is divided into three steps: sub-bleaching, oxygen bleaching, and biological post-treatment:

[0044] Add 1.5% (owf) sodium chlorite and 1% (owf) sodium nitrate during the sub-bleaching process, the pH value is controlled at 2.5, the initial temperature is 30°C, the temperature rises to 50°C, the heating rate is 0.7°C / min, the holding time After 30 minutes, the heat preservation is completed and the drainage liquid is washed to neutral to complete the sub-bleaching; then carry out oxygen bleaching, add 5% (owf) hydrogen peroxide, 4% (owf) sodium silicate, 5% (owf) soda ash, and control the ...

Embodiment 3

[0050] After the flax raw material is combed by a combing machine, it is drawn and combined on the forming and drawing equipment, and then the roving with a fineness of 2.6Nm and a twist of 31T / m is spun on the roving equipment, and then the rovings are placed separately for boiling and bleaching In the equipment, two chemical processes are carried out:

[0051] Chemical treatment process A is divided into three steps: sub-bleaching, oxygen bleaching, and biological post-treatment:

[0052] Add 1.5% (owf) sodium chlorite and 1% (owf) sodium nitrate during the sub-bleaching process, the pH value is controlled at 2.5, the initial temperature is 30°C, the temperature rises to 50°C, the heating rate is 0.7°C / min, the holding time After 30 minutes, the heat preservation is completed and the drainage liquid is washed to neutral to complete the sub-bleaching; then carry out oxygen bleaching, add 5% (owf) hydrogen peroxide, 4% (owf) sodium silicate, 5% (owf) soda ash, and control the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com