Ultrasonic scanner and detection method thereof

A scanner and ultrasonic technology, applied in instruments, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve the problems of inconvenient disassembly and maintenance, complex design structures, and inability to guarantee high precision Ground scanning inspection and other problems, to achieve the effect of easy installation and adjustment, simple structure, and shortened detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Exemplary embodiments, features, and aspects of the present invention will be described in detail below with reference to the accompanying drawings. The same reference numbers in the figures indicate functionally identical or similar elements. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

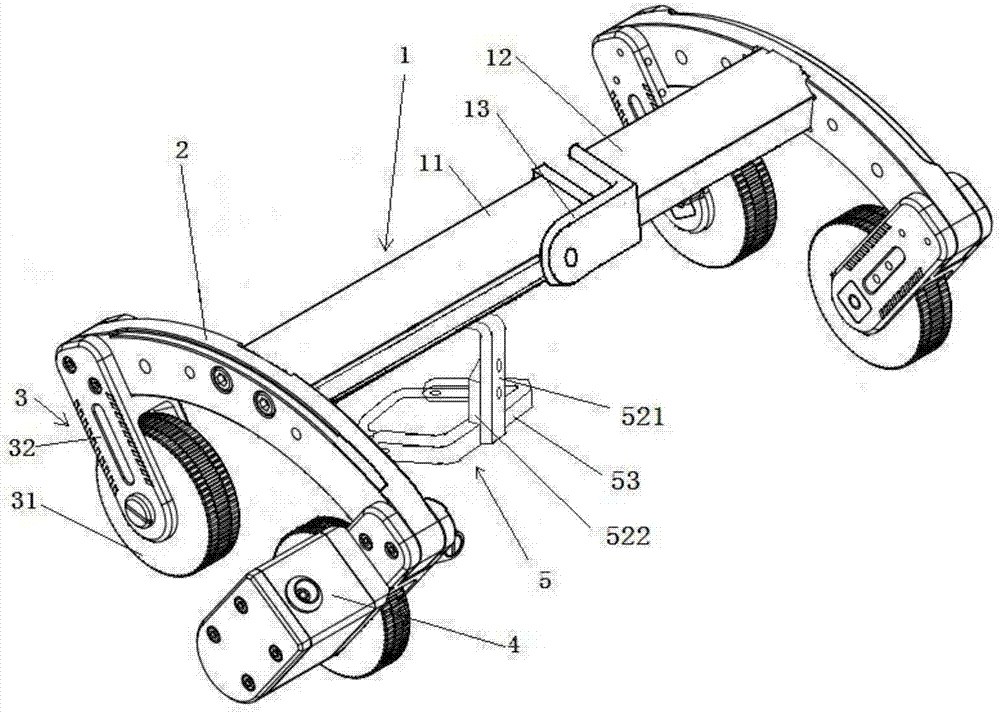

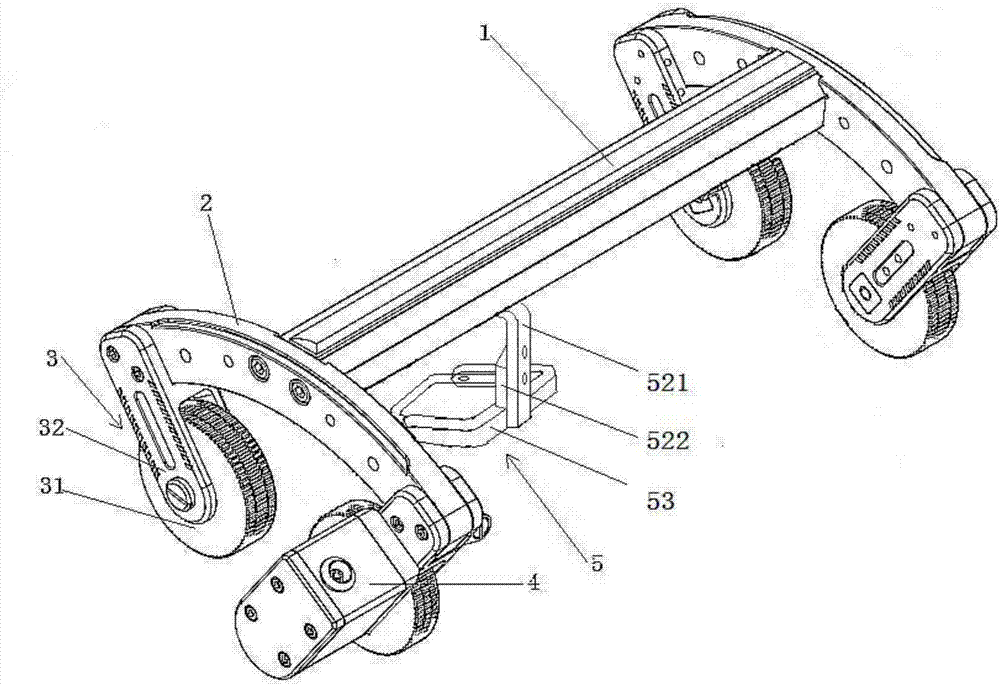

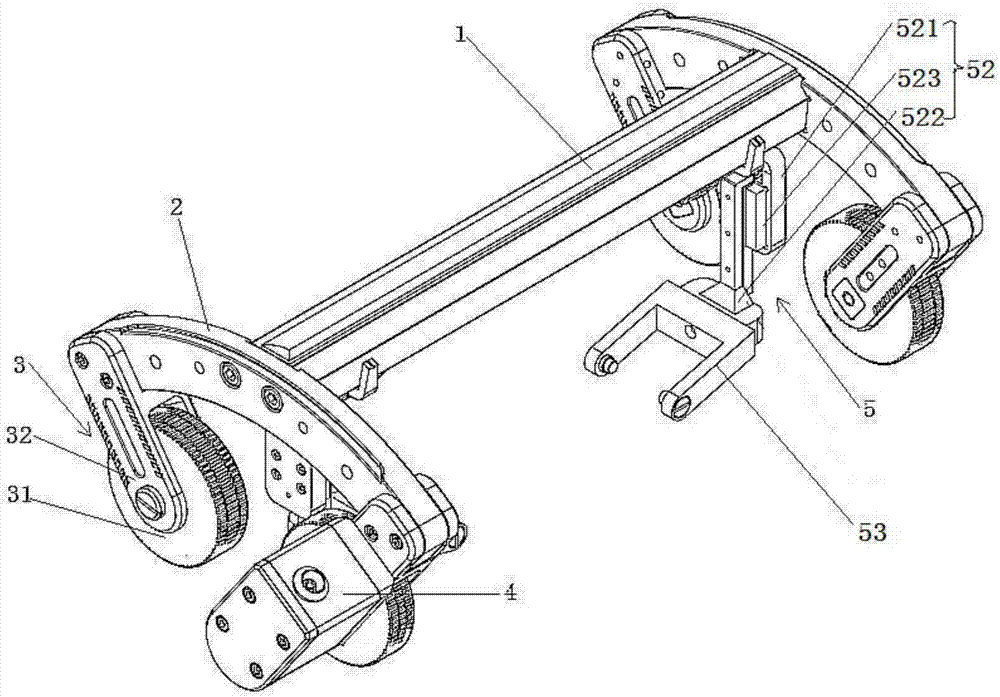

[0033] Such as figure 1 As shown, an ultrasonic scanner includes a main beam 1, an arc arm 2, a magnetic wheel mechanism 3, an encoder 4, and a probe loading arm 5. The main beam 1 includes a long arm 11, a short arm 12 and a connecting long arm 11 and the connecting piece 13 of the short arm 12, the connecting piece 13 is configured to adjust the angle between the long arm 11 and the short arm 12, the angle between the long arm 11 and the short arm 12 is 0-180 °, the long arm 11 and the upper surface of the short arm 12 are provided with scale marks (not shown), the first side of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com