Processing method of barrier layer of chip fuse

A processing method and barrier layer technology, which is applied to electrical components, emergency protection devices, circuits, etc., can solve the problems of lower product quality and pass rate, long time-consuming barrier layer, and low personnel efficiency, so as to improve product quality and pass rate , enhance the properties of resistance to physical shocks, and increase the effect of accumulating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

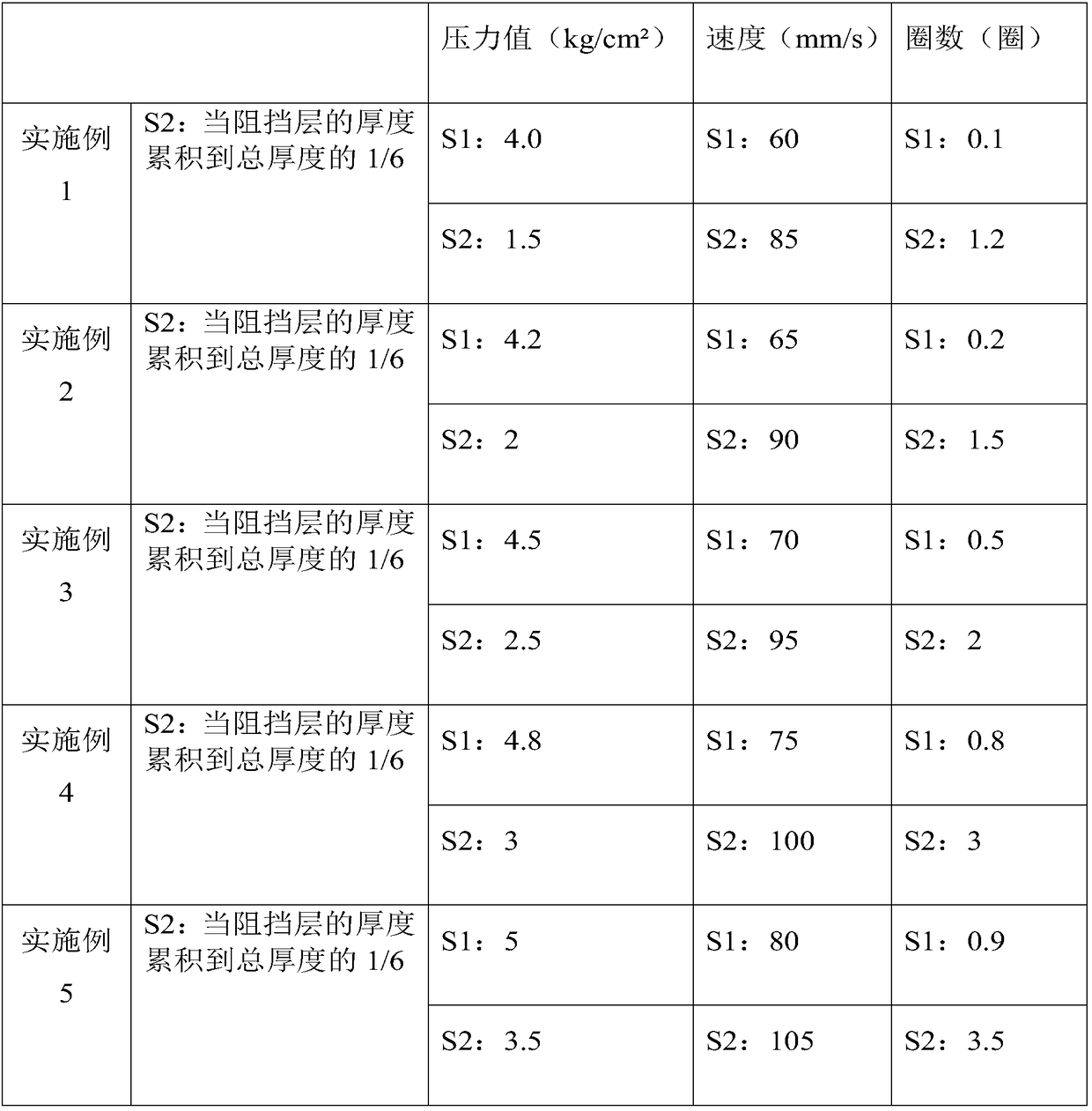

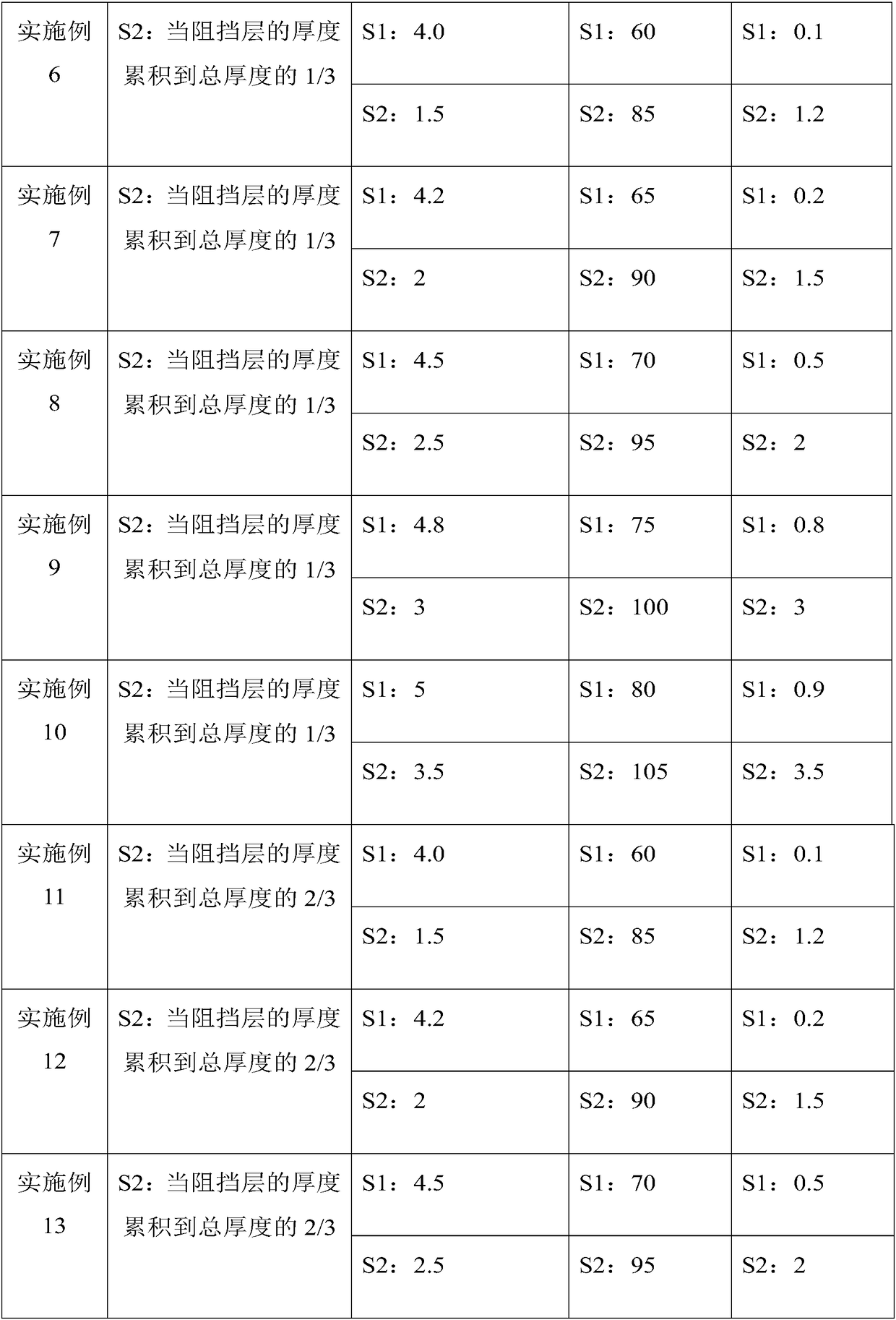

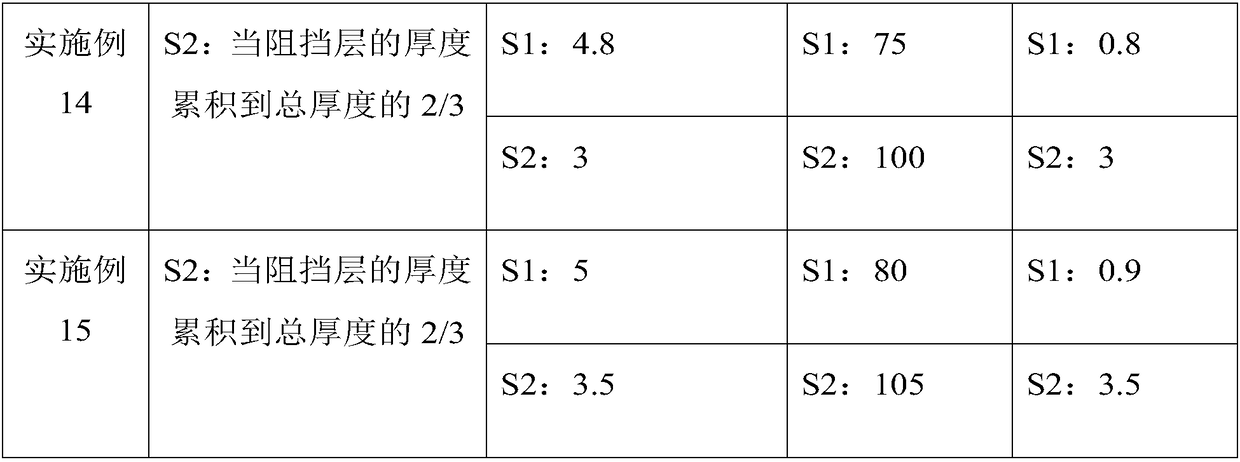

[0036] This embodiment provides a method for processing the barrier layer of a chip fuse, which includes the following steps:

[0037] S1: When printing the barrier layer, the pressure value is 4.0kg / cm 2 , the speed is 60mm / s, the number of turns is 0.1, and the printing is carried out;

[0038] S2: When the thickness of the barrier layer accumulates to 1 / 6 of the total thickness, the pressure value is 1.5kg / cm 2 , the speed is 85mm / s, and the number of turns is 1.2 turns for printing.

[0039] Wipe the screen with a dust-free paper every time the printing of the barrier layer of the chip fuse is completed for 3 pieces.

Embodiment 2

[0041] This embodiment provides a method for processing the barrier layer of a chip fuse, which includes the following steps:

[0042] S1: When printing the barrier layer, the pressure value is 4.2kg / cm 2 , The speed is 65mm / s, the number of turns is 0.2, and the printing is carried out;

[0043] S2: When the thickness of the barrier layer accumulates to 1 / 6 of the total thickness, the pressure value is 2kg / cm 2 , the speed is 90mm / s, and the number of turns is 1.5 turns for printing.

[0044] Wipe the screen with a dust-free paper every time the printing of the barrier layer of the chip fuse is completed for 3 pieces.

Embodiment 3

[0046] This embodiment provides a method for processing the barrier layer of a chip fuse, which includes the following steps:

[0047] S1: When printing the barrier layer, the pressure value is 4.5kg / cm 2 , the speed is 70mm / s, the number of circles is 0.5 circles, and the printing is carried out;

[0048] S2: When the thickness of the barrier layer accumulates to 1 / 6 of the total thickness, the pressure value is 2.5kg / cm 2 , the speed is 95mm / s, and the number of turns is 2 turns for printing.

[0049] Wipe the screen with a dust-free paper every time the printing of the barrier layer of the chip fuse is completed for 3 pieces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com