Processing method of scented tea

A processing method and technology for fragrant tea, applied in the field of tea preparation, can solve problems such as no change, and achieve the effects of convenient operation, green soup color, and lasting aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

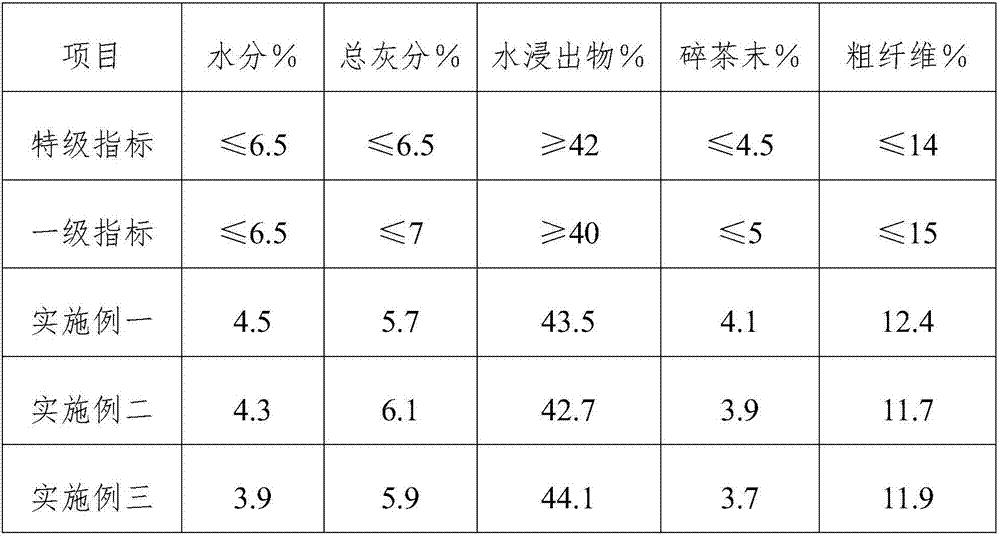

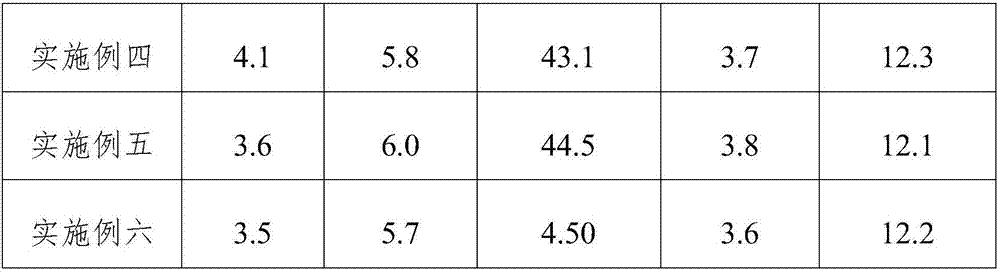

Examples

Embodiment 1

[0024] A processing method of fragrant tea, the method comprises the following steps:

[0025] a. Finishing: use the method of high first and then low for steam finishing, first control the temperature to 120°C for 60s, then quickly lower the temperature to 30°C for 3min, and kill the old leaves tenderly , the young leaves are killed to kill the tea leaves so that the water content is 80%;

[0026] b. Kneading: use the kneading machine to pressurize and knead in the way of light first, then heavy and then light. The young leaves are cold and soft, the old leaves are hot, and the middle-grade leaves are warm. The kneading machine speed is 45r / min, and the kneading time is 45min. , the kneading machine pressurizes and kneads in the way of light first, then heavy and then light. When kneading lightly at first, the gland sinks to 1 / 4 of the amount of leaves thrown, and keeps kneading under this pressure for 20 minutes. When kneading heavily, the gland sinks to Knead at 1 / 2 of the...

Embodiment 2

[0034] A processing method of fragrant tea, the method comprises the following steps:

[0035] a. Finishing: Use the method of high first and then low for steam finishing, first control the temperature to 140°C for 120s, then quickly lower the temperature to 40°C for 5 minutes, and kill the old leaves tenderly , the young leaves are killed to kill the tea leaves so that the water content is 70%;

[0036] b. Kneading: use the kneading machine to pressurize and knead in the way of light first, then heavy and then light. The young leaves are cold and soft, the old leaves are hot, and the middle-grade leaves are warm. The kneading machine speed is 55r / min, and the kneading time is 60min. , the kneading machine pressurizes and kneads in the way of light first, then heavy and then light. When kneading lightly at first, the gland sinks to 1 / 4 of the amount of leaves thrown, and keeps kneading under this pressure for 25 minutes. When kneading heavily, the gland sinks to Knead under t...

Embodiment 3

[0044] A processing method of fragrant tea, the method comprises the following steps:

[0045] a. Finishing: Use the method of high first and then low for steam finishing, first control the temperature to 130°C for 90s, then quickly lower the temperature to 35°C for 4 minutes, and kill the old leaves tenderly , the young leaves are killed to kill the tea leaves so that the water content is 75%;

[0046] b. Kneading: The kneading machine is used to pressurize and knead in the way of light first, then heavy and then light. The young leaves are cold and soft, the old leaves are hot, and the middle-grade leaves are warm. The kneading machine speed is 50r / min, and the kneading time is 77.5 min, the kneading machine pressurizes and kneads in the way of light first, then heavy and then light. When kneading lightly at first, the cover sinks to 1 / 4 of the amount of leaves thrown, and keeps kneading under this pressure for 22.5 minutes. When kneading heavily, the cover is lowered. Sink...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com