Catalytic type infrared sterilization technical method for garlic slices

An infrared sterilization and catalytic technology, applied in food science, food preservation, application, etc., can solve the problems of chemical residue, product quality reduction, economic loss, etc., achieve high energy utilization rate, good product quality, and slow down the effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

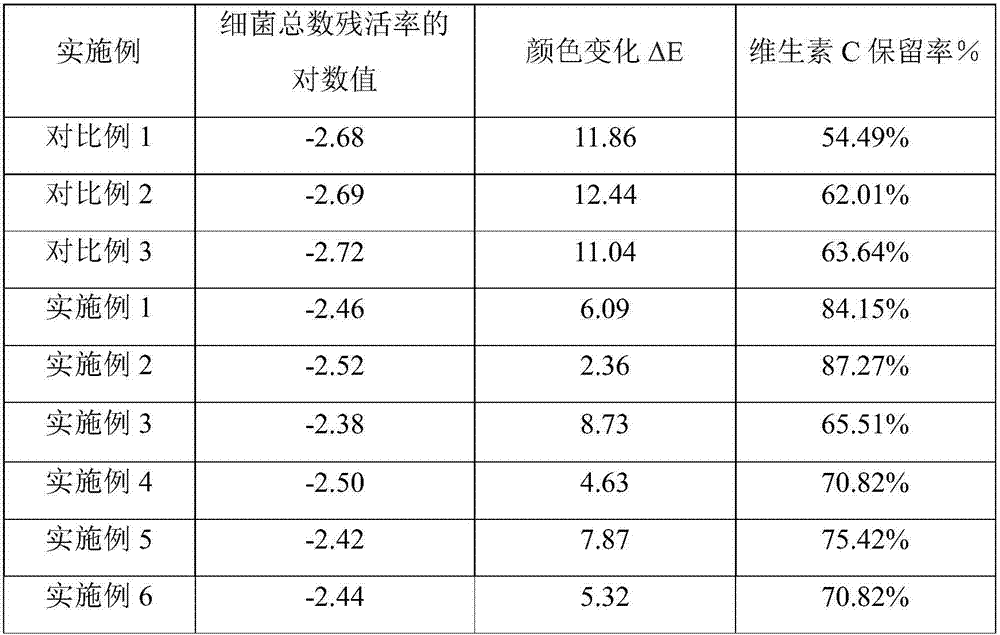

Embodiment 1

[0030] Pick fresh garlic with the same size and no mold and rot, peel it, wash it, and slice it. The thickness of the slice is 3mm. Turn on the upper and lower catalytic infrared generators. The distance between the catalytic infrared generators is 16cm, and the garlic slices are placed in the sample tray for infrared sterilization treatment, and the sterilization time is 120s. Then the logarithmic value, color change and vitamin C retention rate of the total number of bacteria residual rate were determined.

Embodiment 2

[0032] Pick fresh garlic with the same size and no mold and rot, peel it, wash it, and slice it. The thickness of the slice is 3mm. Turn on the upper and lower catalytic infrared generators. The distance between the catalytic infrared generators is 20cm, and the garlic slices are placed in the sample tray for infrared sterilization treatment, and the sterilization time is 210s. Then the logarithmic value, color change and vitamin C retention rate of the total number of bacteria residual rate were determined.

Embodiment 3

[0034] Pick fresh garlic with the same size and no mold and rot, peel it, wash it, and slice it. The thickness of the slice is 5mm. Turn on the upper and lower catalytic infrared generators. The distance between the catalytic infrared generators is 16cm, and the garlic slices are placed in the sample tray for infrared sterilization treatment, and the sterilization time is 150s. Then the logarithmic value, color change and vitamin C retention rate of the total number of bacteria residual rate were determined.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com