Multi-cavity pressureless sintered graphite mold

A graphite mold, multi-cavity technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of inability to achieve synthesis and sintering, waste of energy, and inability to obtain multiple sintered samples at one time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. For the sake of clarity, various parts in the accompanying drawings are not drawn to scale.

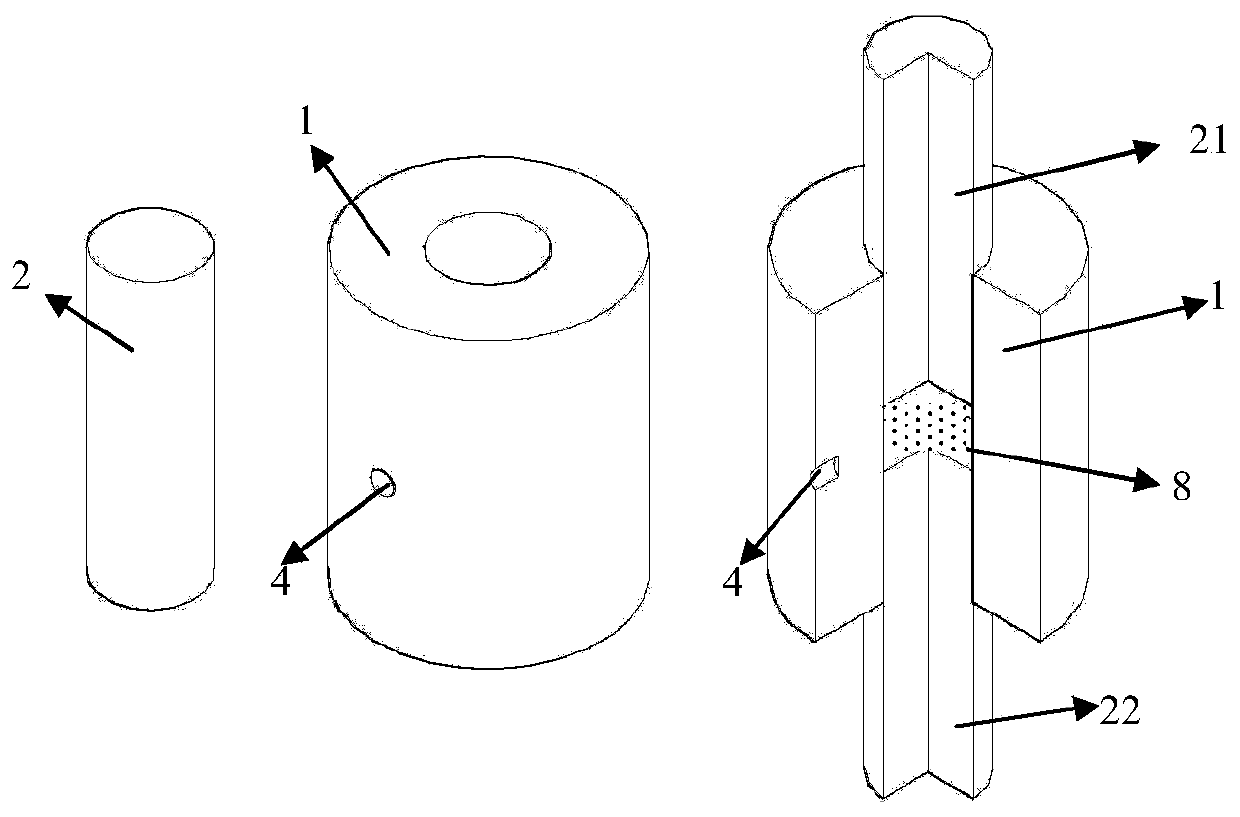

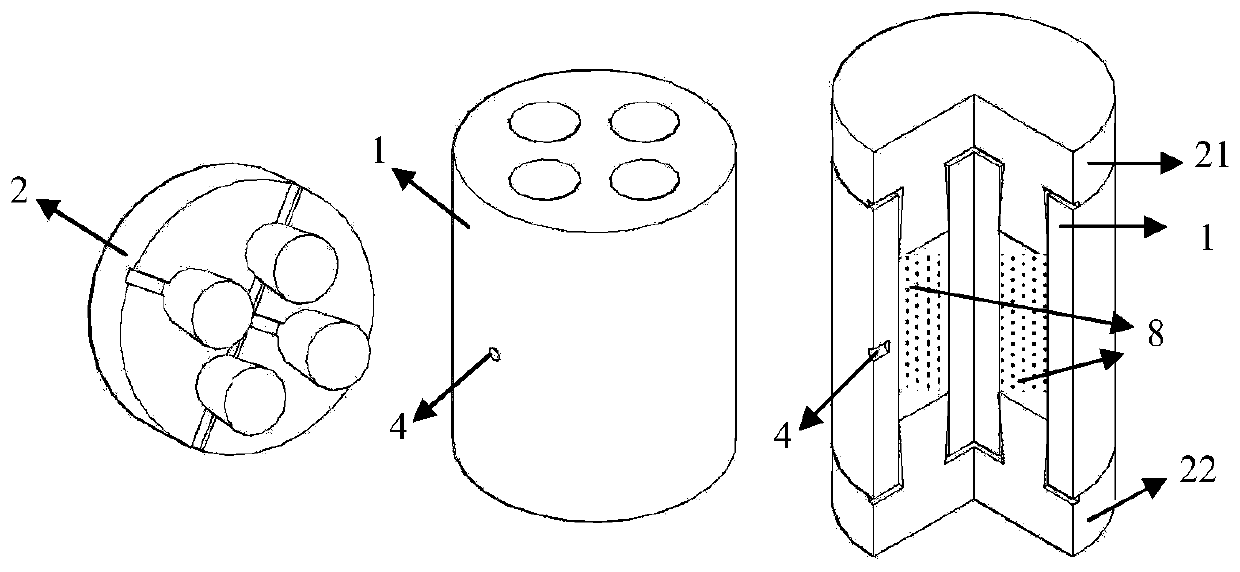

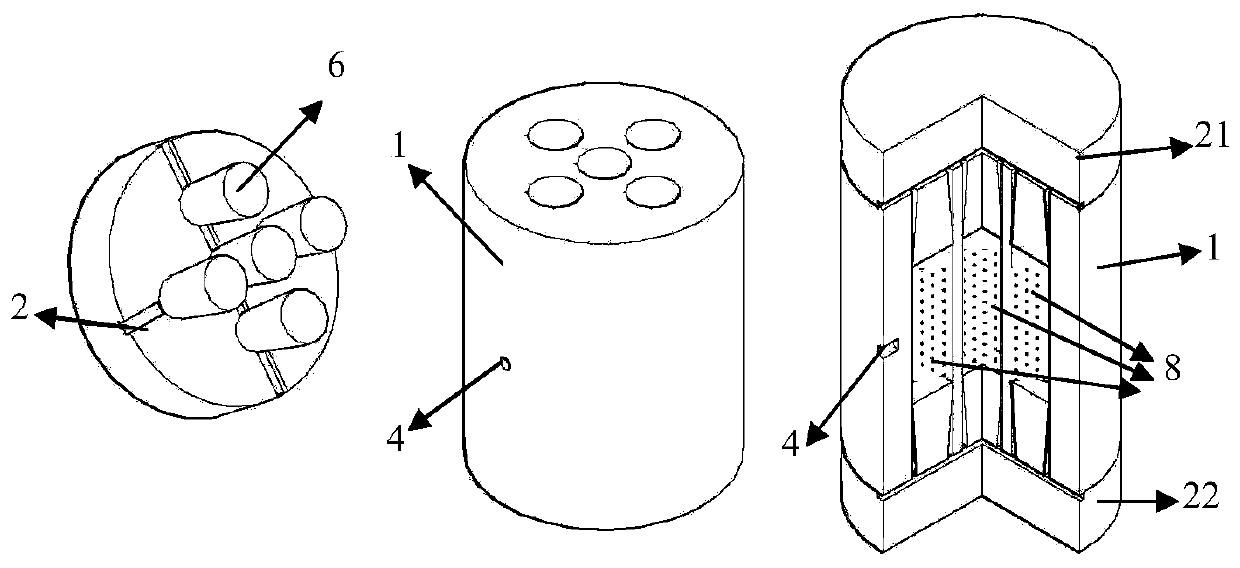

[0027] The present invention provides a graphite mold for multi-cavity pressureless sintering. The whole mold is prepared from graphite, including a graphite sleeve 1, an upper graphite punch 21, a lower graphite punch 22 and a pre-pressing head 3. There are radial temperature measuring holes 4 on the outer wall of the graphite sleeve. The graphite sleeve is a multi-cavity hollow cylinder. The upper graphite punch and the lower graphite punch have the same structure, and the upper graphite punch and the lower graphite punch are opposite to each other. It is arranged at the upper and lower ends of the graphite sleeve respectively, so that the cylindrical protruding rod is located inside the cavity of the graphite sleeve and the material layer 8 is encapsul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com