A non-penetrating laser welding method and system

A laser welding and penetration technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as complex process, difficult to obtain accurately, and back burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

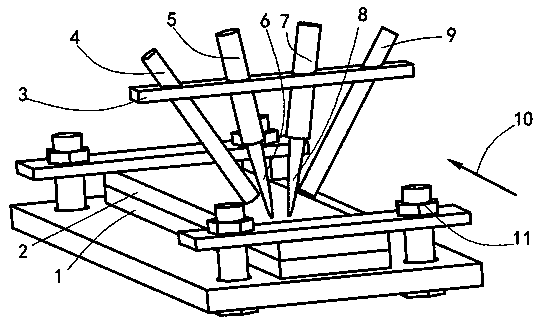

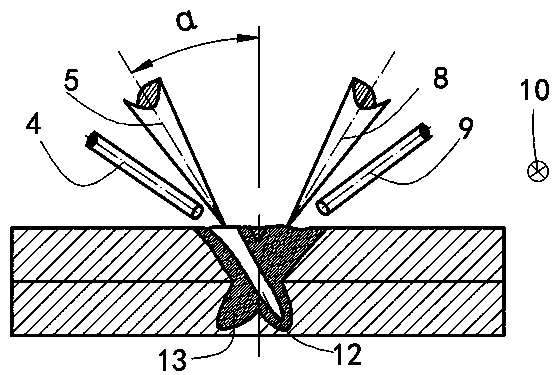

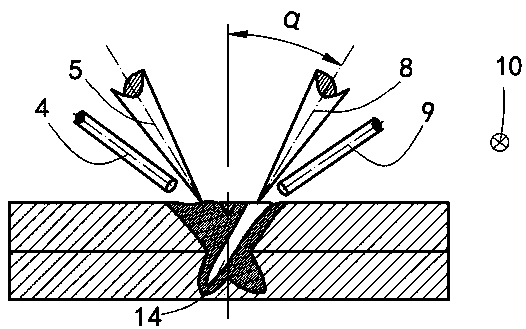

[0032] The following will be combined with Figure 1-5 The technical solution of the present invention will be described in detail along with specific embodiments.

[0033] Such as figure 1 As shown in -5, in the embodiment of the present invention, a non-penetrating double-beam laser welding method includes the following steps.

[0034] Step 1. Provide the first base material 1 and the second base material 2 that need to be welded by lap, which can be prepared and formed by mechanical processing. In this embodiment, the thickness of the first base material 1 and the second base material 2 is 1 mm-5 mm.

[0035] Step 2. Remove the impurities on the upper and lower surfaces of the first base material 1 and the second base material 2, and use the welding fixture 11 to accurately stack and clamp the first base material 1 and the second base material 2 vertically up and down, so that the first base material The material 1 and the second base material 2 are tightly attached unde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com