Method for reducing wear abnormality of guide wheel

A guide wheel and abnormal technology, which is applied in the field of solar photovoltaic slice processing to achieve the effect of prolonging the service life and reducing abnormal wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the invention, not to limit it. this invention.

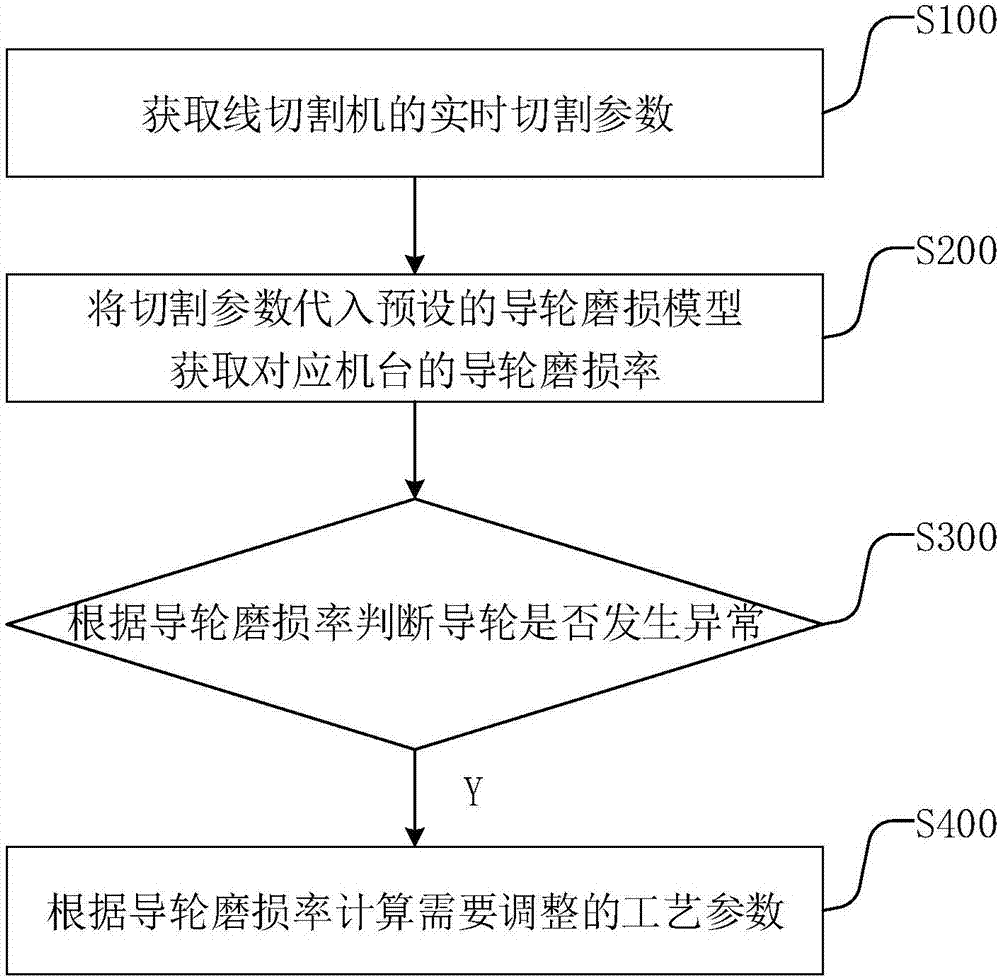

[0036] image 3 The flowchart of the method for reducing abnormal wear of the guide wheel provided by the embodiment of the present application specifically includes the following steps:

[0037] S100: Obtain real-time cutting parameters of the wire cutting machine.

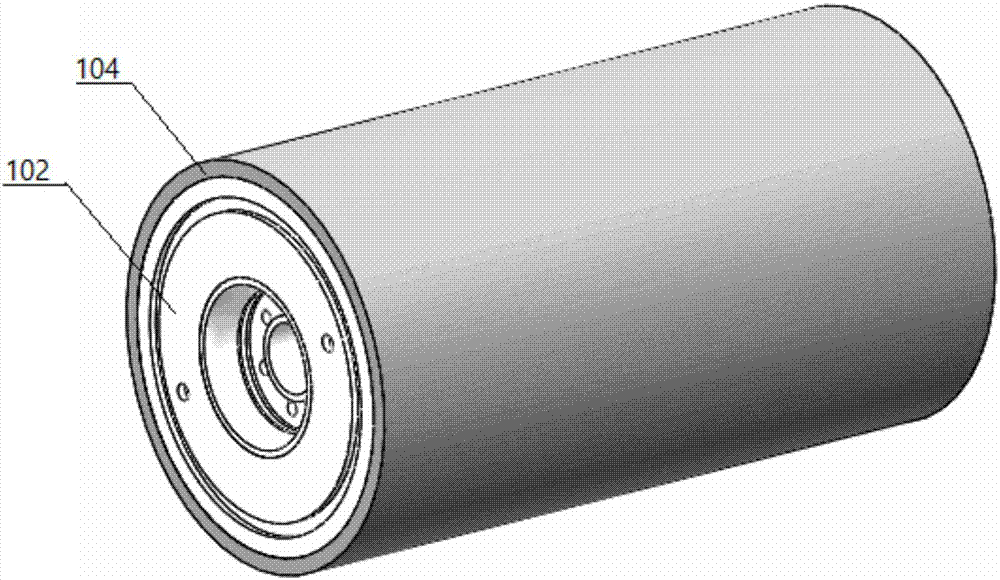

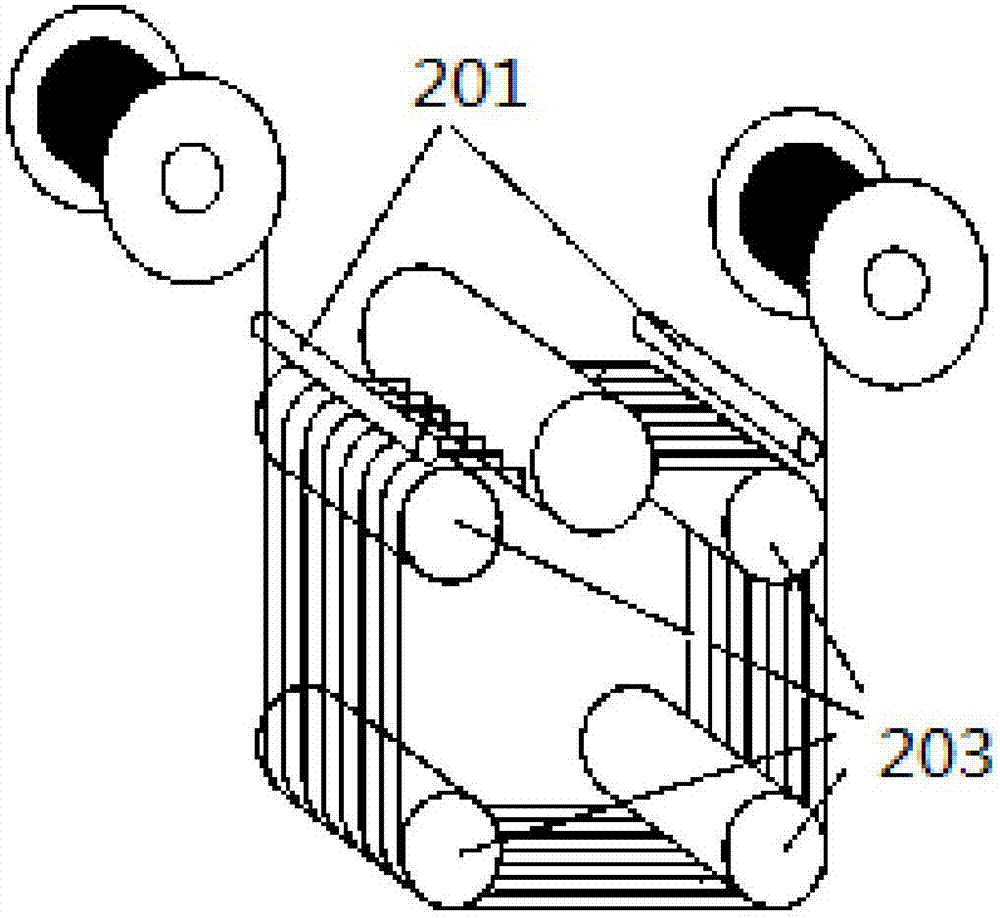

[0038] Among them, the real-time cutting parameters refer to the tension on the steel wire of the cutting machine during the cutting process, the groove width of the guide wheel, the groove angle of the guide wheel, the hardness of the polyurethane material of the guide wheel and the number of cutting knives. The acquisition of real-time cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com