Prow for improving capacity of liquid cargo tank and liquefied gas ship

A technology for liquefied gas tankers and cargo tanks, which is applied in the direction of hull, hull bow, hull parts, etc., can solve the problems of limited cargo tank capacity, the influence of the length and cross-sectional area of the cargo tank, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

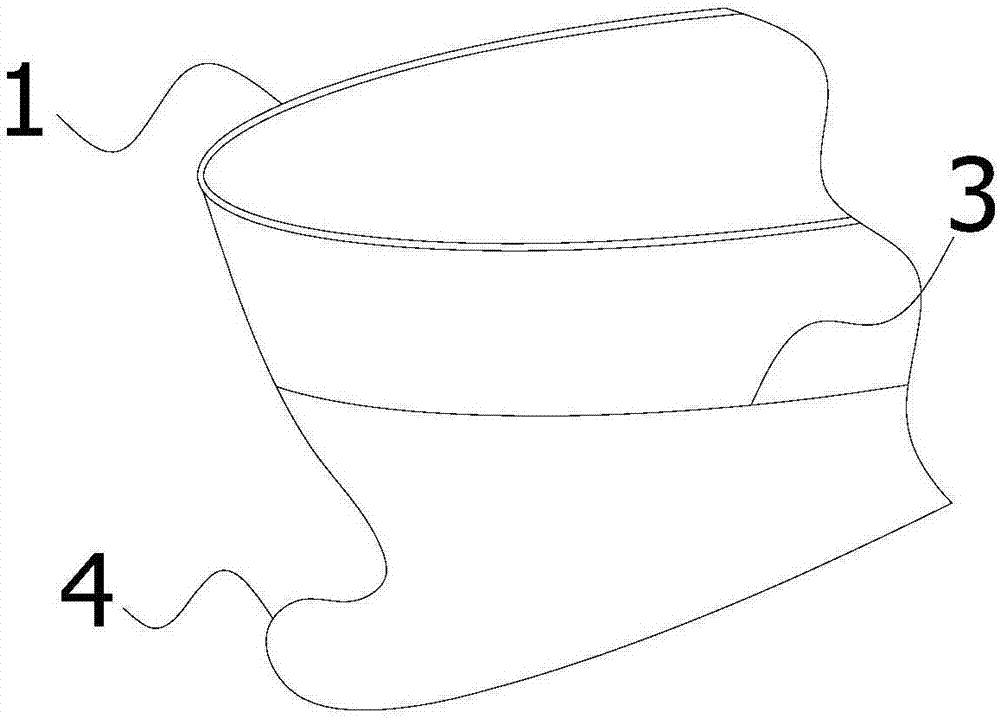

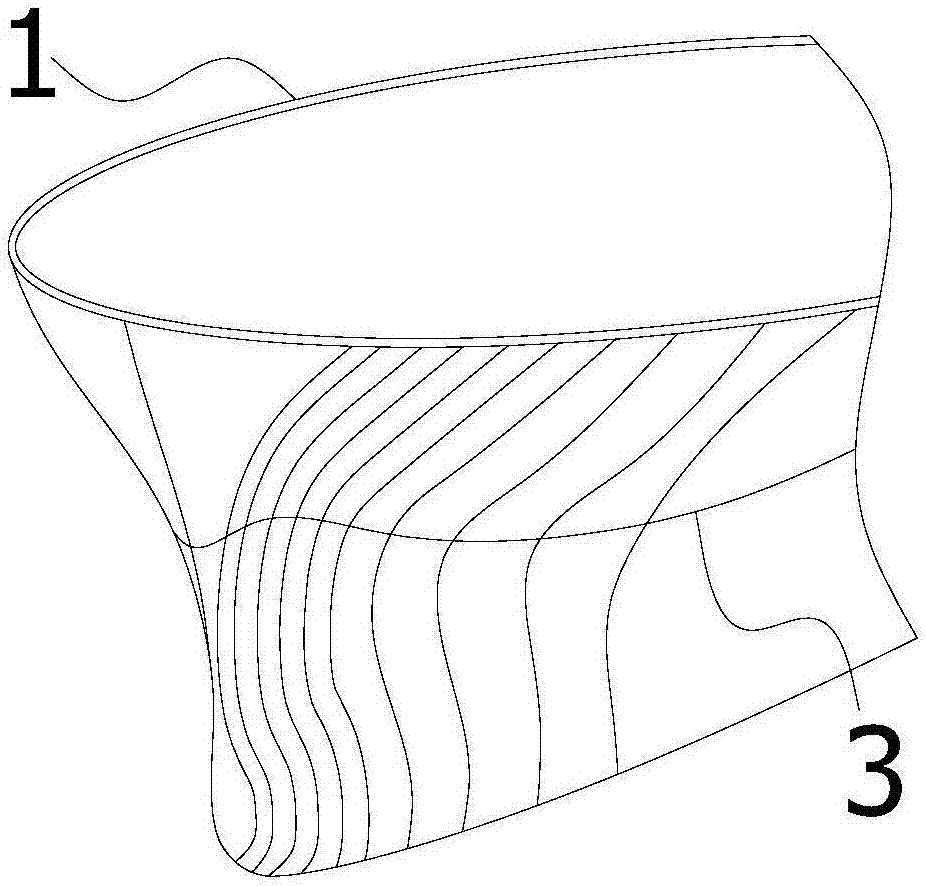

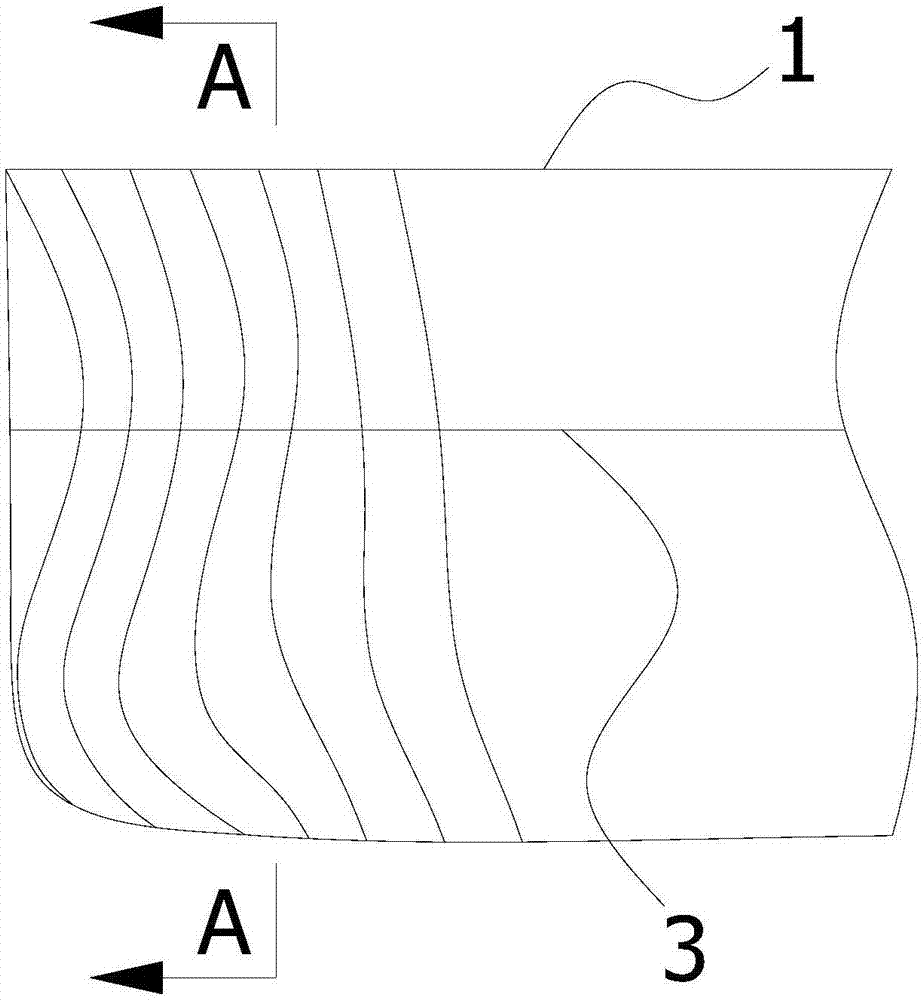

[0039] This embodiment provides a bow for increasing the capacity of a cargo tank, wherein: figure 2 Schematic diagram of the bow structure for increasing the cargo tank capacity provided by the present invention; image 3 The side view of the bow for improving the capacity of the cargo tank provided by the present invention; Figure 4 The lateral cross-sectional view of the bow for increasing the cargo tank capacity provided by the present invention; Figure 5 for image 3 A-A view in the middle. Such as Figure 2~5 As shown, the bow for increasing the capacity of the cargo tank includes the bow hull 1 and the front bulkhead 2 of the cargo tank. Among them, the design waterline half-width H of the bow hull 1 at the front bulkhead 2 of the cargo tank is 30%-50% of the hull half-width H0, and the position of the front bulkhead 2 of the cargo tank reaches 92%-95% from the stern perpendicular The position between the vertical lines.

[0040] The bow of the present invention with i...

Embodiment 2

[0043] This embodiment provides a bow with improved cargo tank capacity. Such as Figure 2~5 As shown, the bow for increasing the capacity of the cargo tank includes the bow hull 1 and the front bulkhead 2 of the cargo tank. Among them, the design waterline half-width H of the bow hull 1 at the front bulkhead 2 of the cargo tank is 30%-50% of the hull half-width H0, and the position of the front bulkhead 2 of the cargo tank reaches 92%-95% from the stern perpendicular The position between the vertical lines.

[0044] Further, the bow of the vessel to increase the cargo tank capacity also includes the bulbous bow 4. Specifically, the line connecting the front edge of the bow hull 1 is a flat line, which is parallel to the height direction of the hull, and the front end of the bulbous bow 4 is located on the rear side of the flat line.

[0045] In this embodiment, the line connecting the front edge of the bow hull 1 is a straight line, and the straight line is parallel to the heig...

Embodiment 3

[0047] This embodiment provides a bow for increasing the capacity of the cargo tank, such as Figure 2~5 As shown, the bow for increasing the capacity of the cargo tank includes the bow hull 1 and the front bulkhead 2 of the cargo tank. Among them, the design waterline half-width H of the bow hull 1 at the front bulkhead 2 of the cargo tank is 30%-50% of the hull half-width H0, and the position of the front bulkhead 2 of the cargo tank reaches 92%-95% from the stern perpendicular The position between the vertical lines.

[0048] Further, the bow of the vessel to increase the cargo tank capacity also includes the bulbous bow 4. Specifically, the line connecting the front edge of the bow hull 1 is a flat line, which is parallel to the height direction of the hull, and the front end of the bulbous bow 4 is located on the rear side of the flat line.

[0049] Furthermore, the bulbous bow 4 is wrapped inside the bow hull 1.

[0050] In this embodiment, since the bulbous bow 4 is wrapped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com