Material transplanting lifter

A lifter and lifting mechanism technology, applied in the field of packaging and conveying equipment, can solve the problems of insufficient connection in the transplanting process, single lifting or transplanting by manpower, and reduced production efficiency, so as to achieve tight connection, small equipment size, and improved production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

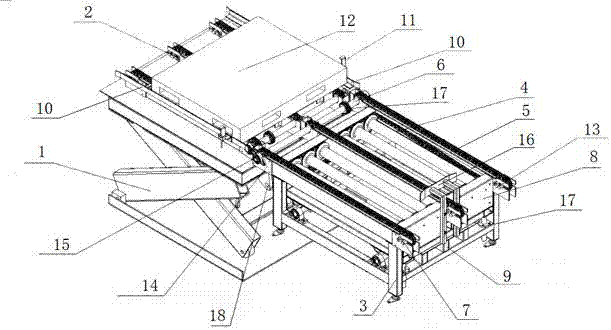

[0014] Such as figure 1 A material transplanting elevator shown includes a lifting mechanism and a horizontal transfer mechanism, and the lifting mechanism and the horizontal transfer mechanism are arranged side by side. The described lifting mechanism includes an elevator 1 and a first transfer sprocket set 2 arranged on the elevator. The horizontal transfer mechanism includes a bracket 3, a roller 4 and a second transfer sprocket set; the second transfer sprocket set includes three chains 5 arranged at intervals on the bracket, a drive shaft 6 at one end of the chain and the other end of the chain The driven shaft 7, the first transfer sprocket group 2 is matched with the second transfer sprocket group; the left and right ends of the support 3 are provided with liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com