Double-station automatic winding machine

An automatic winding machine and dual-station technology, applied in the field of winding, can solve the problems of low work efficiency, many winding machines, occupying space, etc., and achieve the effect of increasing work efficiency, high degree of automation, and low maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

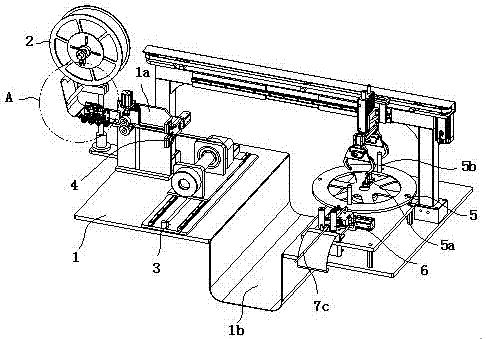

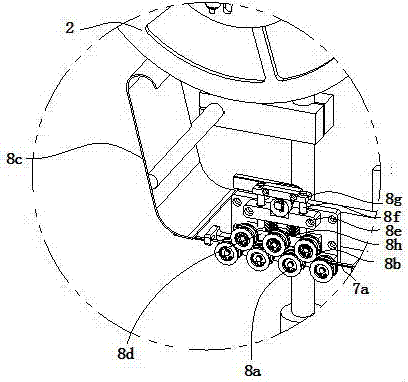

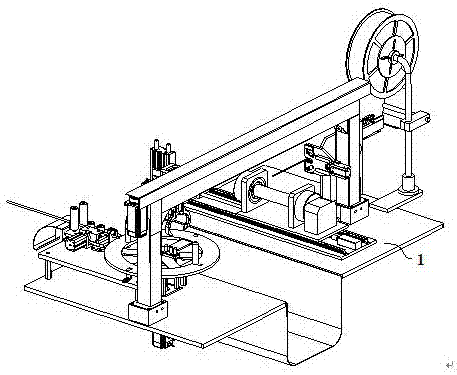

[0023] refer to Figure 1 to Figure 8 A double-station automatic winding machine shown includes a workbench 1, on which a first winding station and a second winding station are arranged at intervals, and the first winding station includes a coil for storing cores. The wire reel 2 of the wire 7a, and the wire winding device 3 for positioning the columnar workpiece 7b and driving its rotation around its own axis. The first wire device on the workpiece 7b, and the tension device 4 for maintaining the tension of the core wire 7a; the second winding station includes a wire storage device for storing the wire 7c, and a turntable 5, the turntable 5 is provided with a fixing column 5a for fixing the wire end of the wire 7c and two coiling columns 5b. In order to guide the wire 7c in the wire storage device into the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com