A method for producing low-silica sodium chloride and sodium sulfate crystalline salt from catalyst wastewater

A technology of sodium chloride and catalyst is applied in the field of wastewater treatment to achieve the effect of improving quality and ensuring long-term operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

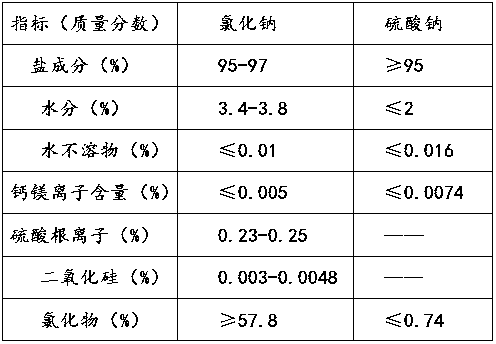

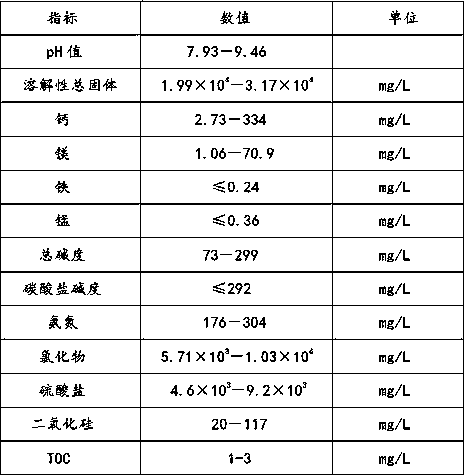

[0034] 1. Catalyst waste water discharged by a refinery catalyst production company is used as the raw water in this example. The specific water quality data are shown in Table 1.

[0035] Table 1 Influent Water Quality

[0036]

[0037] 2. The water quality of sodium chloride and sodium sulfate solution after pretreatment + nanofiltration salt separation + membrane concentration is shown in Table 2.

[0038] Table 2 Water quality table of sodium chloride solution and sodium sulfate solution

[0039]

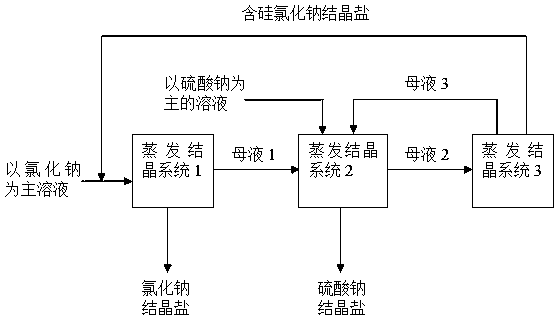

[0040] 3. The sodium chloride solution adjusts the pH value to 10.8, and then enters the MVR evaporative crystallization system 1, and the sodium sulfate solution enters the nitrate co-production evaporative crystallization system (MVR+secondary flash evaporation+crystallization process), and at the same time the mother liquor of the MVR evaporative crystallization system 1 It also enters the nitrate cogeneration evaporation crystallization system, the mother liquor of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com