Application of a cemented filling material containing straw fiber in filling mining

A cemented filling material and straw fiber technology, which is applied in the field of mine filling materials, can solve the problems of low utilization rate of fine-grained tailings, high cement unit consumption, poor crack resistance, etc., achieve wide application significance and promotion value, reduce unit cost Consumption, improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] The mass ratio of the fine-grain tailings fiber cemented filling material of the present invention is as follows:

[0071] 1 part of straw fiber, 249 parts of cement, 995 parts of fine tailings, and 763 parts of water.

[0072] Straw fiber length 1 ~ 3cm.

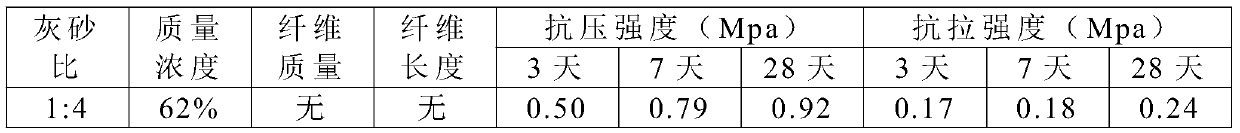

[0073] This embodiment was tested for compressive and tensile properties, and the results are shown in Table 2.

[0074] Table 2 embodiment 1 performance measurement result

[0075]

[0076] Comparing the experimental results of Example 1 and Comparative Example 1, it can be seen that adding the straw fiber helps to improve the compressive strength and tensile strength.

Embodiment 2

[0097] The mass ratio of the fine-grain tailings fiber cemented filling material of the present invention is as follows:

[0098] 1 part of straw fiber, 205 parts of cement, 1024 parts of fine tailings, and 753 parts of water.

[0099] Straw fiber length 1 ~ 3cm.

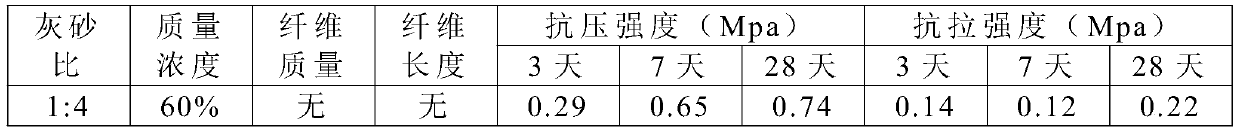

[0100] The embodiment was tested for compressive and tensile properties, and the results are shown in Table 4.

[0101] Table 4 embodiment 2 performance measurement result

[0102]

[0103] Comparing Example 2 and Comparative Example 2, it can be seen that adding the straw fiber helps to improve the compressive strength and tensile strength. In addition, Comparative Example 1 and Comparative Example 2 found that the use of cement was reduced, and the strength decreased significantly, but it was found through Comparative Example 1 and Example 2 that under the premise of reducing the amount of cement, through the addition of the straw fiber, Its various strengths can be close to or better than the experimental r...

Embodiment 3

[0105] The mass ratio of the fine-grain tailings fiber cemented filling material of the present invention is as follows:

[0106] 0.5 parts of straw fiber, 205 parts of cement, 1024 parts of fine tailings, and 753 parts of water.

[0107] Straw fiber length 1 ~ 3cm.

[0108] This embodiment was tested for compressive and tensile properties, and the results are shown in Table 5.

[0109] Table 5 embodiment 3 performance measurement result

[0110]

[0111] Comparing Example 2 and Example 3, it can be seen that in the case of reducing the amount of fiber added, the compressive strength and tensile strength of the filling body are both reduced, and the mechanical properties of the filling body are deteriorated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com