A kind of red mud-based foam light soil and preparation method thereof

A technology of foam lightweight soil and red mud, which is applied in the field of building materials, can solve the problem of difficulty in realizing large-scale utilization of red mud, and achieve the effects of improving strength and reducing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A preparation method of red mud-based foam light soil, comprising the following steps:

[0050] 1) Weighing raw materials: including 217 parts of red mud, 11 parts of desulfurized gypsum, 309 parts of cement, 273 parts of water, and 21 parts of foam.

[0051] 2) Stir the weighed water, desulfurized gypsum and red mud at a speed of 1400 rpm for 5 minutes, then add cement and stir at a speed of 1400 rpm for 5 minutes.

[0052] 3) Reduce the rotational speed to 700rpm, add foam and stir for 2 minutes, and adjust the density of the obtained slurry to 800kg / m 3 , the red mud-based foam light soil can be obtained.

[0053] 4) The red mud-based foam lightweight soil can be poured into shape to obtain the red mud-based foam lightweight soil specimen.

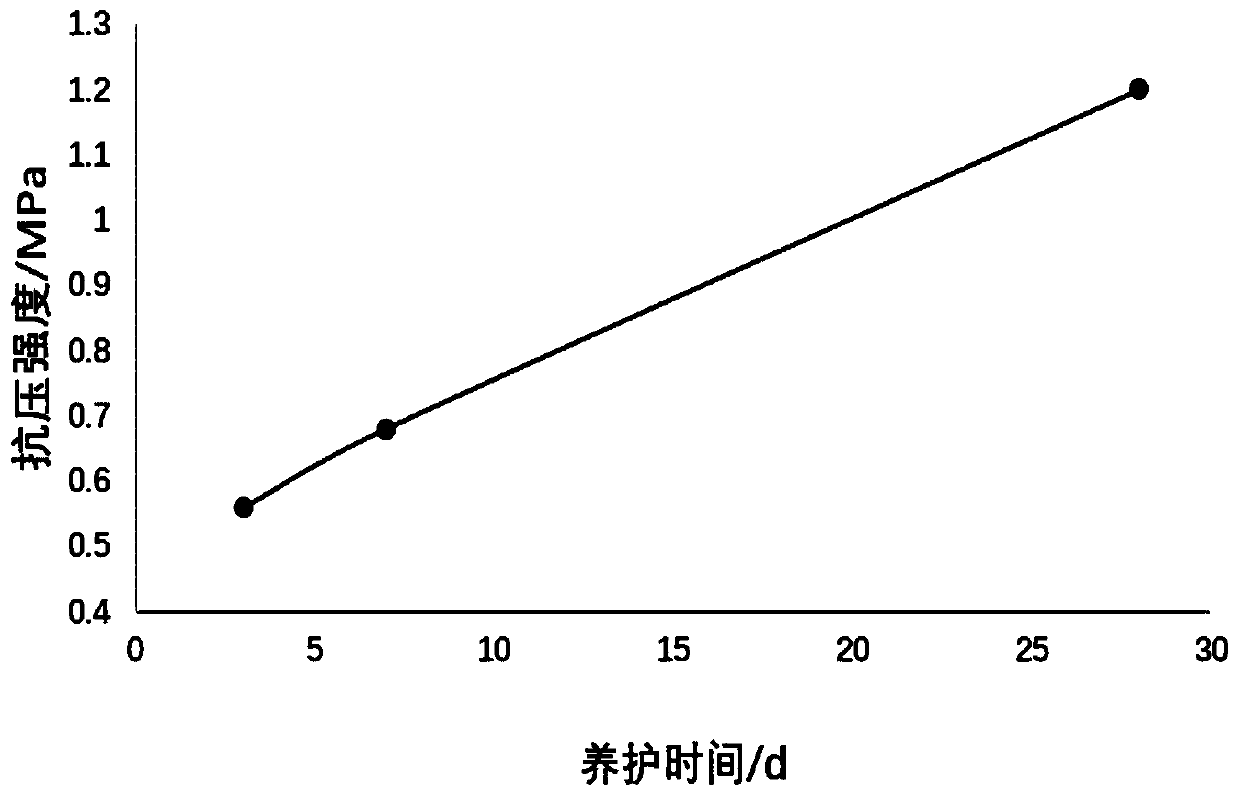

[0054] like figure 1 and Figure 4 As shown, the red mud-based foam lightweight soil specimens prepared in this example were tested for compressive strength and elastic modulus, and the 28d compressive strength was 1.2MPa, an...

Embodiment 2

[0056] A preparation method of red mud-based foam light soil, comprising the following steps:

[0057] 1) Weighing raw materials: including 271 parts of red mud, 14 parts of desulfurized gypsum, 271 parts of cement, 270 parts of water, and 22 parts of foam.

[0058] 2) Stir the weighed water, desulfurized gypsum and red mud at a speed of 1400 rpm for 7 minutes, then add cement and stir at a speed of 1400 rpm for 7 minutes.

[0059] 3) Reduce the rotation speed to 700rpm, add foam and stir for 2.5min, and adjust the density of the obtained slurry to 800kg / m 3 , the red mud-based foam light soil can be obtained.

[0060] 4) The red mud-based foam lightweight soil can be poured into shape to obtain the red mud-based foam lightweight soil specimen.

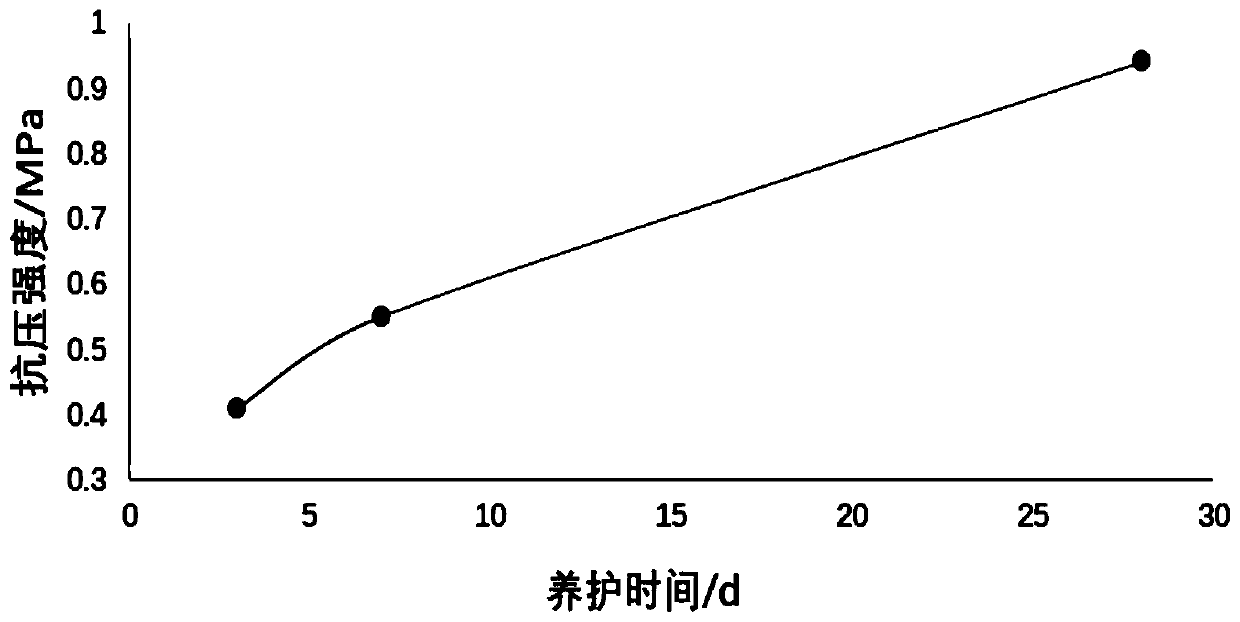

[0061] like figure 2 and Figure 5 As shown, the red mud-based foam lightweight soil specimens prepared in this example were tested for compressive strength and elastic modulus, and the 28-day compressive strength was 0.94MPa, an...

Embodiment 3

[0063] A preparation method of red mud-based foam light soil, comprising the following steps:

[0064] 1) Weighing raw materials: including 325 parts of red mud, 16 parts of desulfurized gypsum, 207 parts of cement, 267 parts of water, and 23 parts of foam.

[0065] 2) Stir the weighed water, desulfurized gypsum and red mud at a speed of 1400 rpm for 10 minutes, then add cement and stir at a speed of 1400 rpm for 10 minutes.

[0066] 3) Reduce the rotational speed to 700rpm, add foam and stir for 3 minutes, and adjust the density of the obtained slurry to 800kg / m 3 , the red mud-based foam light soil can be obtained.

[0067] 4) The red mud-based foam lightweight soil can be poured into shape to obtain the red mud-based foam lightweight soil specimen.

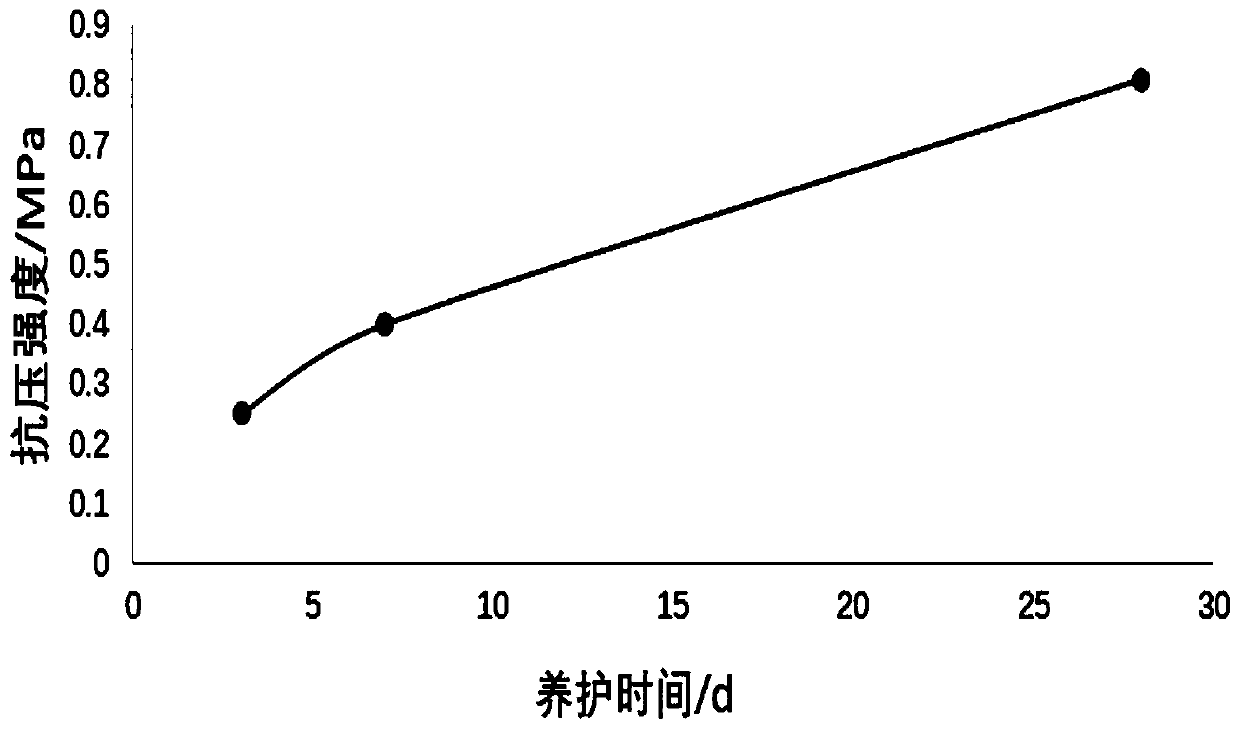

[0068] like image 3 and 6 As shown, the red mud-based foam lightweight soil specimens prepared in this example were tested for compressive strength and elastic modulus, and the 28-day compressive strength was 0.81 MPa, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com