Novel packaging boxboard and packaging box

A packaging box and a new type of technology are applied in the field of packaging box boards and packaging boxes assembled by using the packaging box boards, which can solve the problem of the number of times that wood cannot be recycled for secondary use or recycled use, has no environmental protection significance, and is not easy to handle. Lifting and other problems, to achieve the effect of satisfying multiple cycles, enhancing mechanical meshing force, and improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

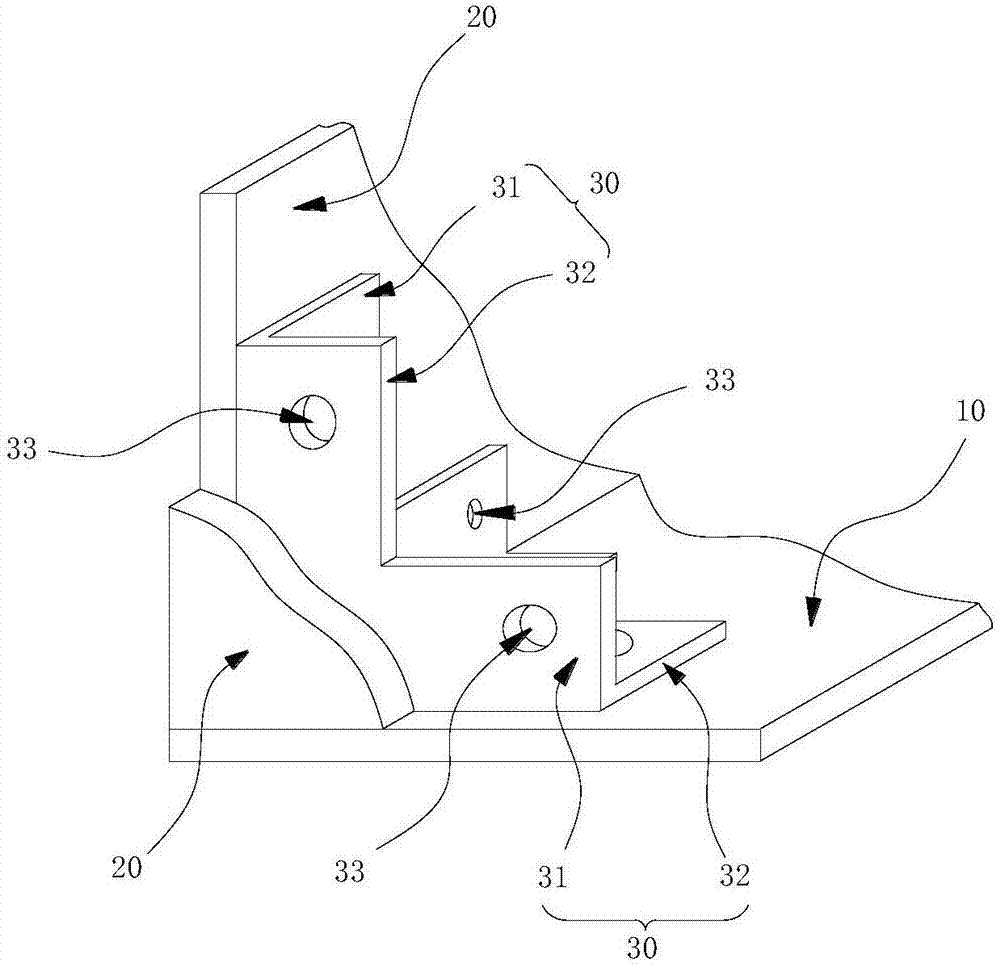

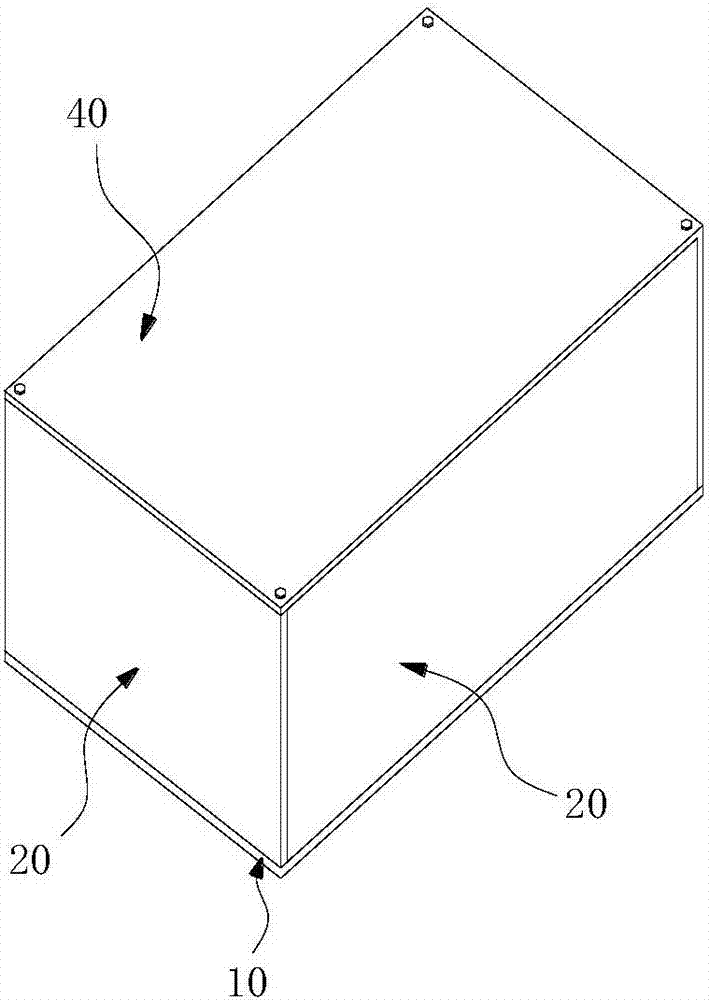

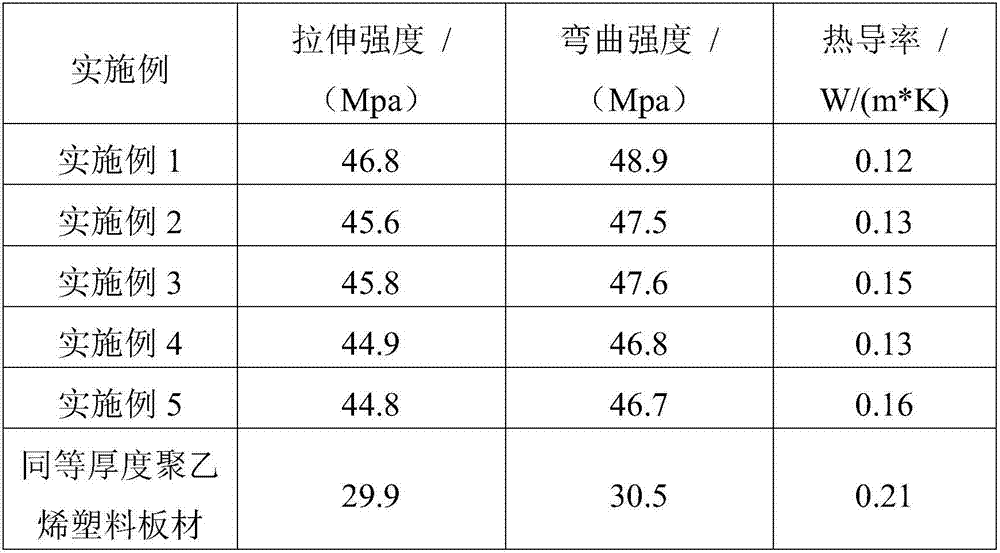

[0023] Such as figure 1 , 2 As shown, a packing box, the bottom plate 10 of the packing box is provided with a corner block 30 adjacent to the side wall plate 20, and the corner block 30 includes first and second connecting plates 31, 32. The first and second connecting plates 31 and 32 are respectively provided with threaded holes 33 for bolts to connect the bottom plate 10 and the side wall plate 20; the edge of the cover plate 40 of the packing box is provided with connecting holes for bolts to pass through fixed to the upper end of the side wall panel 20.

[0024] The bottom plate 10, the side wall plate 20, and the cover plate 40 include the following materials in parts by weight: 90 parts of polyethylene, 12 parts of iron powder, 0.5 parts of sodium hexametaphosphate, 8 parts of glass fiber, 14 parts of polyethylene fiber, shell 5 parts of powder, 5 parts of kaolin, 4 parts of talcum powder; the glass fiber and polyethylene fiber are modified by hydrochloric acid.

Embodiment 2

[0026] Such as figure 1 , 2 As shown, a packing box, the bottom plate 10 of the packing box is provided with a corner block 30 adjacent to the side wall plate 20, and the corner block 30 includes first and second connecting plates 31, 32. The first and second connecting plates 31 and 32 are respectively provided with threaded holes 33 for bolts to connect the bottom plate 10 and the side wall plate 20; the edge of the cover plate 40 of the packing box is provided with connecting holes for bolts to pass through fixed to the upper end of the side wall panel 20.

[0027] The bottom plate 10, the side wall plate 20, and the cover plate 40 include the following parts by weight: 80 parts of polypropylene, 10 parts of iron powder, 0.1 part of sodium hexametaphosphate, 5 parts of glass fiber, 8 parts of polyethylene fiber, shell powder 2 parts, kaolin 3 parts, talcum powder 1 part; the glass fiber and polyethylene fiber are modified by sulfuric acid.

Embodiment 3

[0029] Such as figure 1 , 2 As shown, a packing box, the bottom plate 10 of the packing box is provided with a corner block 30 adjacent to the side wall plate 20, and the corner block 30 includes first and second connecting plates 31, 32. The first and second connecting plates 31 and 32 are respectively provided with threaded holes 33 for bolts to connect the bottom plate 10 and the side wall plate 20; the edge of the cover plate 40 of the packing box is provided with connecting holes for bolts to pass through fixed to the upper end of the side wall panel 20.

[0030] The bottom plate 10, the side wall plate 20, and the cover plate 40 include the following parts by weight: 95 parts of polyvinyl chloride, 15 parts of iron powder, 1 part of sodium hexametaphosphate, 12 parts of glass fiber, 16 parts of polyethylene fiber, 7 parts of shell powder, 8 parts of kaolin, and 5 parts of talcum powder; the glass fiber and polyethylene fiber are modified by nitric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com