A kind of preparation method of coal-water slurry

A coal-water slurry and slurry technology, which is used in fuel additives, liquid carbon-containing fuels, petroleum industry, etc., can solve problems such as increasing the difficulty of storage and transportation and production costs, low quality of coal-water slurry products, and unstable thermodynamics. , to achieve the effect of changing interfacial tension and hydrophilic and hydrophobic properties, increasing storage stability and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

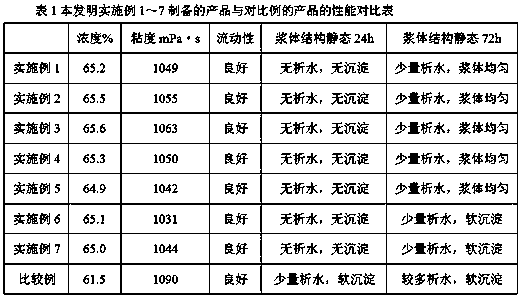

Examples

Embodiment 1

[0030] 1) Crushing and coarsely grinding the raw coal to obtain the first pulverized coal with an average particle size of 200 µm, mixing the first pulverized coal and water at a mass ratio of 3.5:1, adding 1 wt% of the total mass The first additive is mixed by a planetary mixer to obtain the first slurry;

[0031] 2) Finely grind the first pulverized coal to obtain the second pulverized coal with an average particle size of 100µm, mix the second pulverized coal with water at a mass ratio of 3:1, add 1.5% of the total mass The second additive of wt%, is mixed homogeneously through planetary mixer, obtains the second slurry;

[0032] 3) Secondary fine grinding of the second pulverized coal to obtain the third pulverized coal with an average particle size of 20µm, mixing the third pulverized coal with water at a ratio of 2:1, adding 2wt of the total mass % of the third additive, mixed uniformly through a planetary mixer, to obtain the third slurry;

[0033] 4) Ultrafine grindi...

Embodiment 2

[0037] 1) Crushing and coarsely grinding the raw coal to obtain the first pulverized coal with an average particle size of 300 µm, mixing the first pulverized coal and water at a mass ratio of 5:1, adding 1 wt% of the total mass The first additive is mixed by a planetary mixer to obtain the first slurry;

[0038] 2) Finely grind the first pulverized coal to obtain the second pulverized coal with an average particle size of 50µm, mix the second pulverized coal with water at a mass ratio of 4:1, and add 2wt of the total mass % of the second additive, mixed uniformly through a planetary mixer, to obtain the second slurry;

[0039] 3) The second pulverized coal is finely ground for the second time to obtain the third pulverized coal with an average particle size of 30µm, and the third pulverized coal is mixed with water at a ratio of 2:1, adding 3wt of the total mass % of the third additive, mixed uniformly through a planetary mixer, to obtain the third slurry;

[0040] 4) Ultra...

Embodiment 3

[0044] 1) Crushing and coarsely grinding the raw coal to obtain the first pulverized coal with an average particle size of 150 µm, mixing the first pulverized coal and water at a mass ratio of 3:1, adding 1 wt% of the total mass The first additive is mixed by a planetary mixer to obtain the first slurry;

[0045] 2) Finely grind the first pulverized coal to obtain the second pulverized coal with an average particle size of 50µm, mix the second pulverized coal with water at a mass ratio of 2:1, and add 1wt of the total mass % of the second additive, mixed uniformly through a planetary mixer, to obtain the second slurry;

[0046] 3) The second pulverized coal is finely ground for the second time to obtain the third pulverized coal with an average particle size of 15µm, and the third pulverized coal is mixed with water in a ratio of 1:1, adding 1wt of the total mass % of the third additive, mixed uniformly through a planetary mixer, to obtain the third slurry;

[0047] 4) Ultra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com