A Method for Reducing Pore Defects of Laser Cladding Molding Parts

A laser cladding molding and laser cladding technology, applied in the field of additive manufacturing, can solve the problems of difficulty in completely eliminating porosity defects and the concentration effect of gas in the molten pool, achieving a simple and efficient experimental plan and reducing porosity defects. , the effect of good packing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

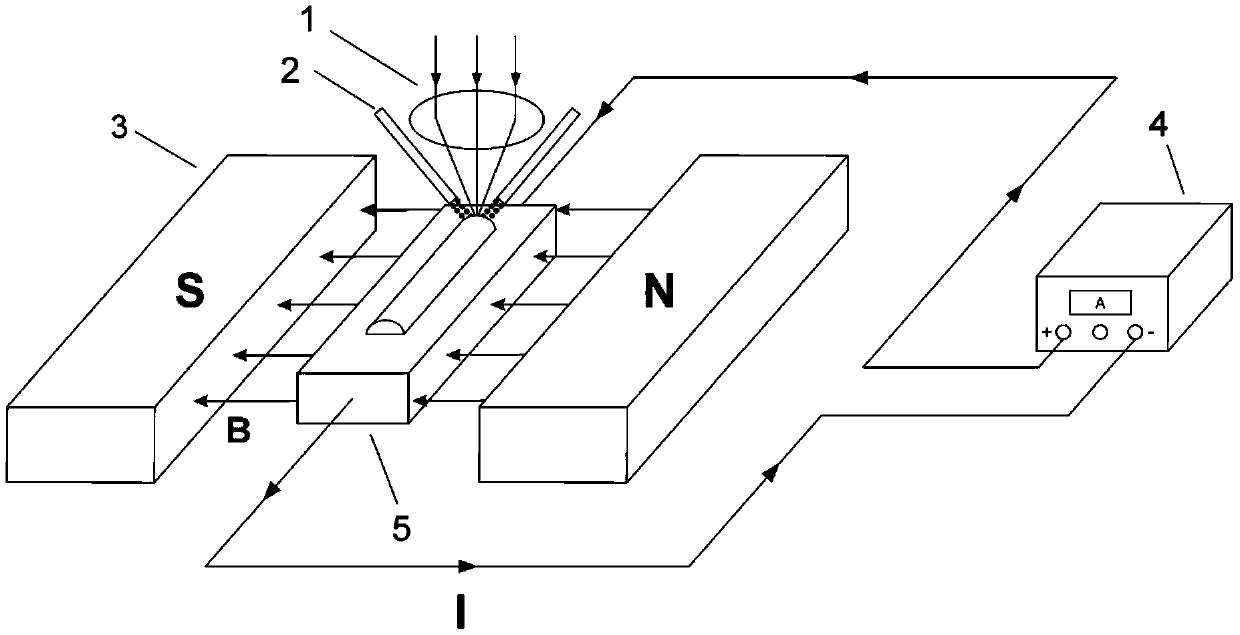

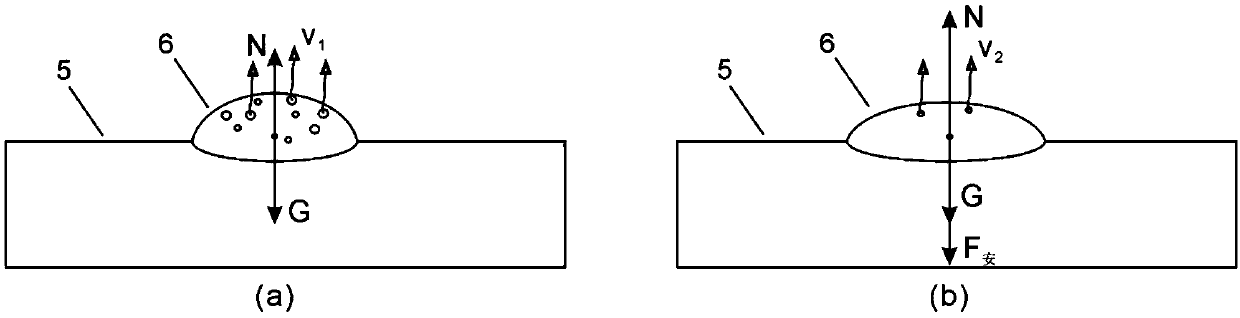

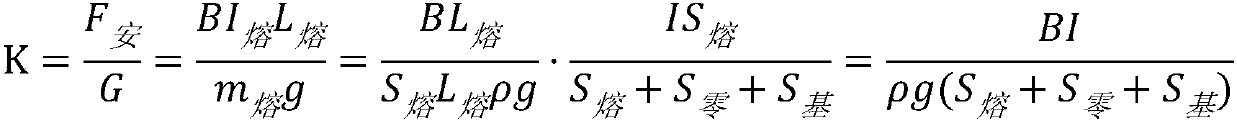

[0032] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0033] 1) Clean the cladding substrate 5 according to the conventional cleaning method in this field: immerse the cladding substrate 5 in an acetone solution, and clean it with an ultrasonic cleaner at a temperature of 30-40°C for 20-25 minutes, thereby removing the cladding substrate 5 surface dirt; after the cleaning is completed, dry the acetone solution remaining on the surface of the cladding substrate 5 .

[0034] 2) The cladding substrate 5 is placed in the constant magnetic field generator 3 so that it is in a uniformly distributed directional magnetic field environment. After the cladding substrate 5 is placed, fix it with a clamp to avoid position shift under the action of subsequent electromagnetic force.

[0035] 3) Connect the cladding substrate 5 with the positive and negative poles of the DC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com