Anti-crease anti-microbial shirt fabric and manufacturing and finishing process thereof

A technology for fabrics and shirts, which is applied in the field of anti-wrinkle and antibacterial shirt fabrics and its production and finishing technology. It can solve the problems of weak anti-fouling ability, poor anti-wrinkle effect, troublesome cleaning of shirts, etc., achieve breathability, comfort, water absorption, increase elasticity, and improve anti-fouling. The effect of the antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

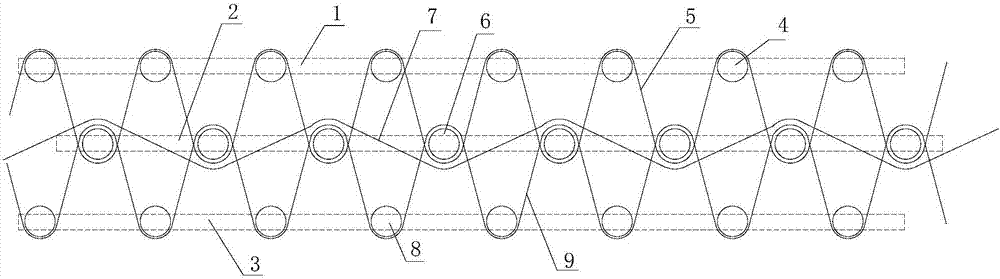

[0028] Such as figure 1 As shown, an anti-wrinkle and antibacterial shirt fabric includes an outer layer 1, a middle layer 2 and an inner layer 3. The fabric mainly includes the following components according to a mass ratio: cotton fiber 40%-60%, milk protein fiber 10 %-20%, bamboo charcoal fiber 10%-20%, polyester fiber 5%-10% and PTT fiber 5%-10%, the outer layer 1 is made of bamboo charcoal fiber and polyester fiber blended, and the middle layer 2 is made of cotton Fiber and PTT fiber are blended. The inner layer 3 is made of milk protein fiber and cotton fiber. The outer layer 1 and the middle layer 2 are woven together by the outer weft yarns and the middle warp yarns. The middle layer 2 and the inner layer Between 3, the inner layer weft yarn and the middle layer warp yarn are interwoven into a whole.

[0029] The polyester fiber and bamboo charcoal fiber are blended as the outer layer of the first warp yarn 4 and the first weft yarn 5, the PTT fiber and cotton fiber are ...

Embodiment 2

[0035] A manufacturing and finishing process of waterproof and breathable fabric for windbreaker mainly includes the following steps:

[0036] (1) Material selection and weighing: According to the mass ratio, weigh out 60% cotton fiber, 15% milk protein fiber, 15% bamboo charcoal fiber, 5% polyester fiber and 5% PTT fiber for the raw material components;

[0037] (2) Spinning: separate cotton fiber, milk protein fiber, bamboo charcoal fiber, polyester fiber and PTT fiber into strips, and then blend bamboo charcoal fiber and polyester fiber, 30% cotton fiber and PTT fiber, and 30% cotton fiber respectively Blended with milk protein fiber to form a roving, which is twisted to form a spun yarn, and then the spun yarn is made into a cone yarn;

[0038] (3) Dyeing of cone yarn: the main steps are: loosening cone-loading cage-dyeing-drying-rewinding cone, loose yarn density is 0.35g / cm 3 ;

[0039] (4) Warping: place the cone yarn on the warping machine for slitting and warping into warp ya...

Embodiment 3

[0045] A manufacturing and finishing process of waterproof and breathable fabric for windbreaker mainly includes the following steps:

[0046] (1) Material selection and weighing: According to the mass ratio, weigh 40% cotton fiber, 20% milk protein fiber, 20% bamboo charcoal fiber, 10% polyester fiber and 10% PTT fiber for the raw material components;

[0047] (2) Spinning: separate cotton fiber, milk protein fiber, bamboo charcoal fiber, polyester fiber and PTT fiber into strips, and then blend bamboo charcoal fiber and polyester fiber, 20% cotton fiber and PTT fiber, and 20% cotton fiber. Blended with milk protein fiber to form a roving, which is twisted to form a spun yarn, and then the spun yarn is made into a cone yarn;

[0048] (3) Dyeing of cone yarn: the main steps are: loose tube-cage-dyeing-drying-rewinding, the density of loose yarn is 0.42g / cm 3 ;

[0049] (4) Warping: place the cone yarn on the warping machine for slitting and warping into warp yarn;

[0050] (5) Sizing: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com