Slab-column structure assembly system and floor slab prefabricated components and connection nodes thereof

A technology of prefabricated components and connecting nodes, applied in the direction of floors, building components, building structures, etc., can solve problems such as difficulty, high cost, and non-structural form, and achieve the goal of reducing precision requirements, simplifying work difficulty, and improving assembly efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

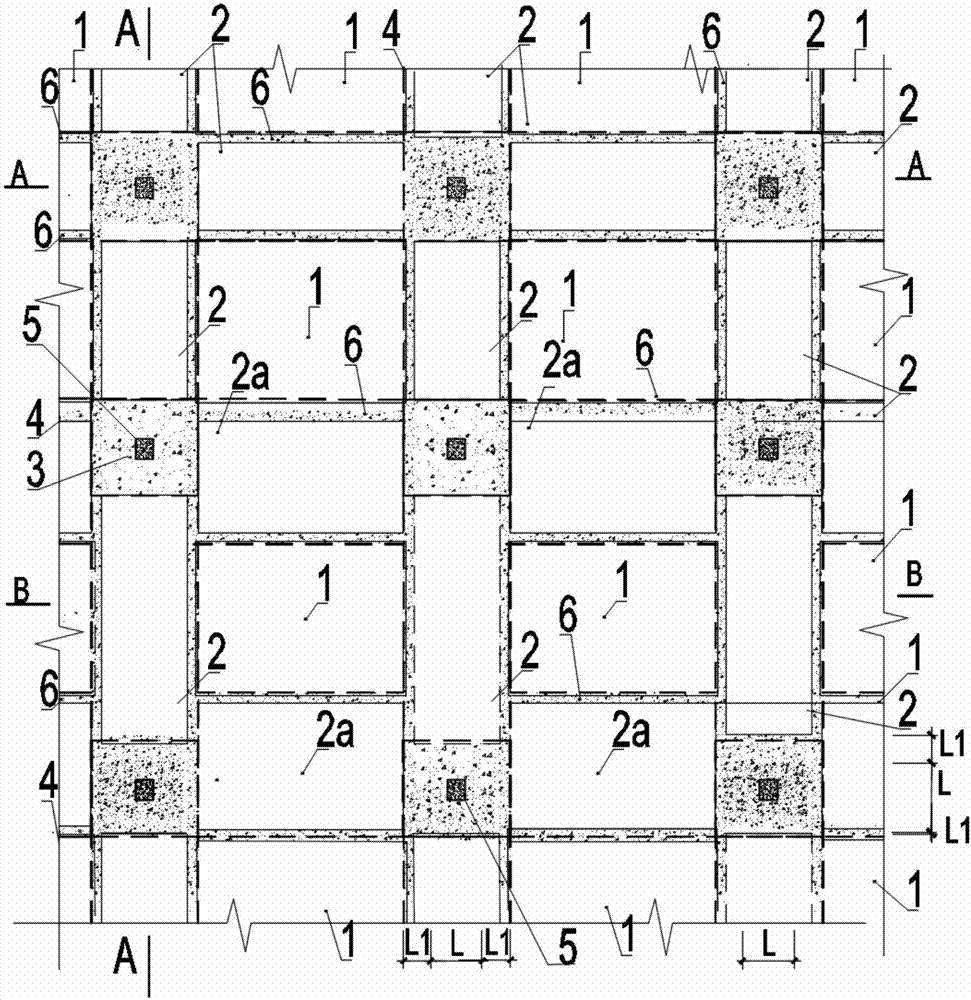

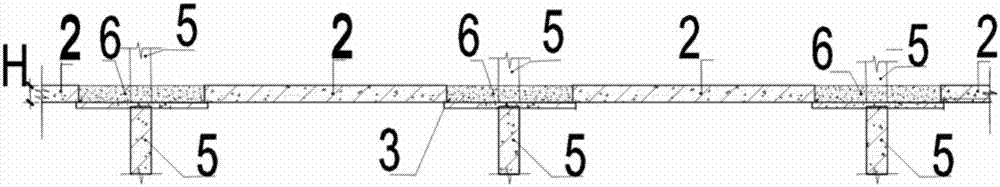

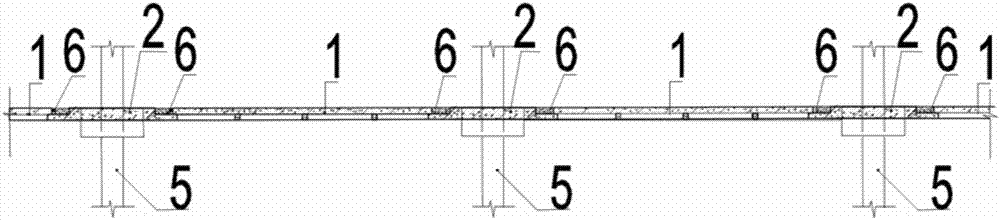

[0067] like Figure 1-23 As shown, the slab-column structure assembly system includes column 5, prefabricated component 1 with ribbed floor slab without column cap connecting plate ( Figure 4-9 , 3 forms are listed) and the prefabricated component 2 with column cap connection plate and floor slab (such as Figure 10-11 ) and 2a ( Figure 12-13 ), prefabricated pallet 3, connecting nodes. The prefabricated supporting plate 3 is consistent with the name agreement and stipulation content of the national code "Code for Design of Concrete Structures" GB50010-2010 and "Code for Seismic Design of Buildings" GB50010-2011, and the prefabricated supporting plate is an enlarged supporting plate (such as Figure 14 single-stage pallet shown). The prefabricated component with ribbed floor slab without column cap connection plate 1, the prefabricated component with column cap connection plate and floor slab 2 has connection reinforcement reserved on four sides, and the connection reinfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com