Composite metal tube

A composite metal pipe and metal pipe technology are applied to the composite metal pipe. It can solve the problems of corrosion resistance reliability, economic indicators are difficult to balance, and it is difficult to meet the needs of oil and gas field development, and achieve excellent mechanical properties, good corrosion resistance, and the effect of reducing dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

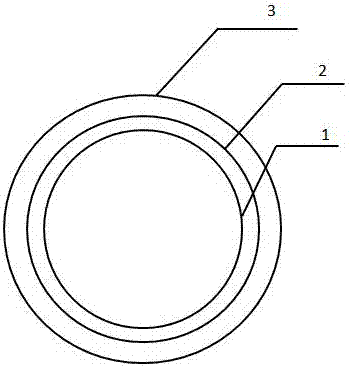

[0017] Such as figure 1 As shown, the present invention provides a composite metal pipe. The metal pipe is composed of a carbon steel pipe body, a corrosion-resistant alloy layer and an anti-corrosion coating from the inside of the pipe body axis to the outside. The carbon steel pipe body and the corrosion-resistant alloy layer are form a closed space.

[0018] As a preference, the anti-corrosion coating is a graphene water-based coating layer.

[0019] Further, the carbon steel pipe body and the corrosion-resistant alloy layer are combined through a hot rolling process.

[0020] The metal plate used in this embodiment is a steel pipe, and the two pipes are coaxially superimposed. The inner pipe and the outer pipe are expanded at the same time through the hydraulic expansion method or the explosion method, so that the inner pipe undergoes a large plastic deformation and the outer pipe undergoes a smaller deformation. Elastic deformation, after the pressure is released, the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com