Spherical pin element positioning algorithm based on point matching

A technology of pin components and positioning algorithm, applied in the direction of calculation, graphic image conversion, image data processing, etc., can solve the problem of lack of spherical pin chip position and angle, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

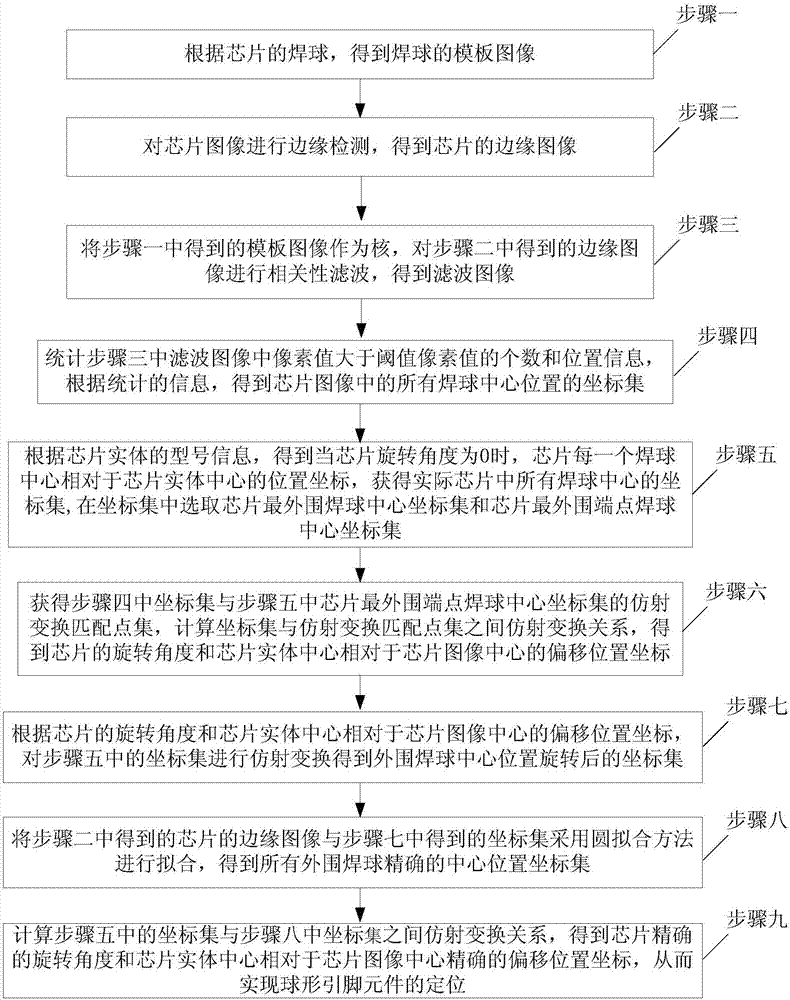

[0022] Specific implementation mode one: refer to Figure 1 to Figure 5 Describe this embodiment in detail, a kind of positioning algorithm based on the spherical pin element of point matching described in this embodiment, this algorithm comprises the following steps:

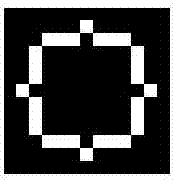

[0023] Step 1. According to the solder balls of the chip, the template image of the solder balls is obtained;

[0024] Step 2, performing edge detection on the chip image to obtain an edge image of the chip;

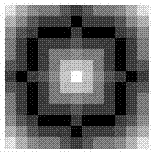

[0025] Step 3, using the template image obtained in step 1 as a core, performing correlation filtering on the edge image obtained in step 2 to obtain a filtered image;

[0026] Step 4: Count the number and position information of the pixel values greater than the threshold pixel value in the filtered image in step 3, and obtain the coordinate set of the center positions of all solder balls in the chip image according to the statistical information

[0027] Step 5. According to the model information ...

specific Embodiment approach 2

[0034] Specific embodiment two: This embodiment is a further description of a positioning algorithm based on point-matching spherical pin components described in specific embodiment one. In this embodiment, in step five, the coordinates of the centers of all solder balls set , select the center coordinate set of the outermost solder ball of the chip and the coordinate set of the center coordinates of the outermost solder ball of the chip The specific process is:

[0035] Since the BGA chip solder balls are arranged in a matrix, the point with the smallest vertical coordinate of the solder ball center in the leftmost column (x 2 ,y 2 ) and the point with the largest ordinate (x 4 ,y 4 ), the point with the smallest vertical coordinate of the solder ball center in the rightmost column (x 0 ,y 0 ) and the point with the largest ordinate (x 6 ,y 6 ), the point with the smallest abscissa of the solder ball center on the uppermost row (x 3 ,y 3 ) and the point with the...

specific Embodiment approach 3

[0036]Specific embodiment three: This embodiment is a further description of a positioning algorithm based on point-matching spherical pin components described in specific embodiment one. In this embodiment, in step six, the coordinate set in step four is obtained and the center coordinate set of the outermost solder ball of the chip in step 5 The affine transformation of the matching point set The specific process is:

[0037] First calculate the center coordinate set of the outermost solder ball of the chip The distance between each coordinate point in the chip image, and then the coordinate set of all solder ball center positions in the chip image Search for a group of points with the closest distance between coordinate points, as an affine transformation matching point set

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com