Sealing wear-ring dynamic/static state exciting force effect characteristic parameter testing device and method

A characteristic parameter and testing device technology, which is applied in the direction of measuring device, vibration testing, mechanical component testing, etc., to achieve the effect of comprehensive testing parameters, simplified experimental device and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

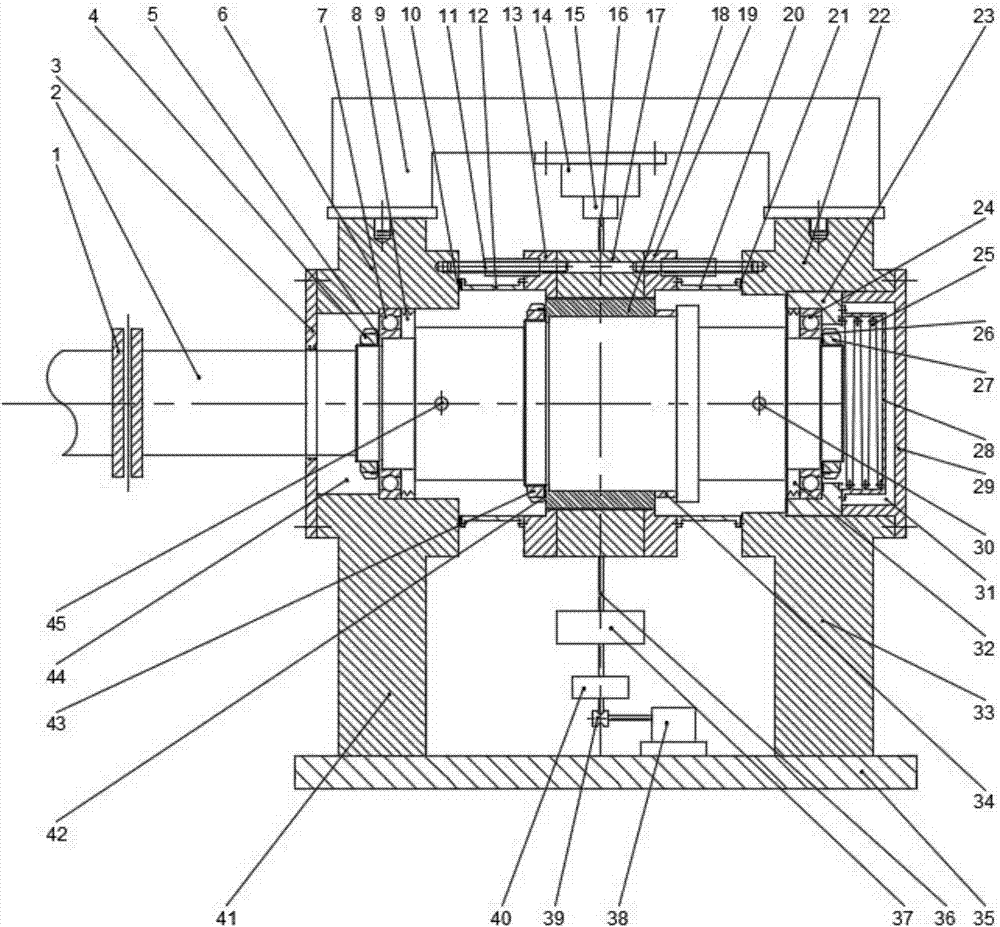

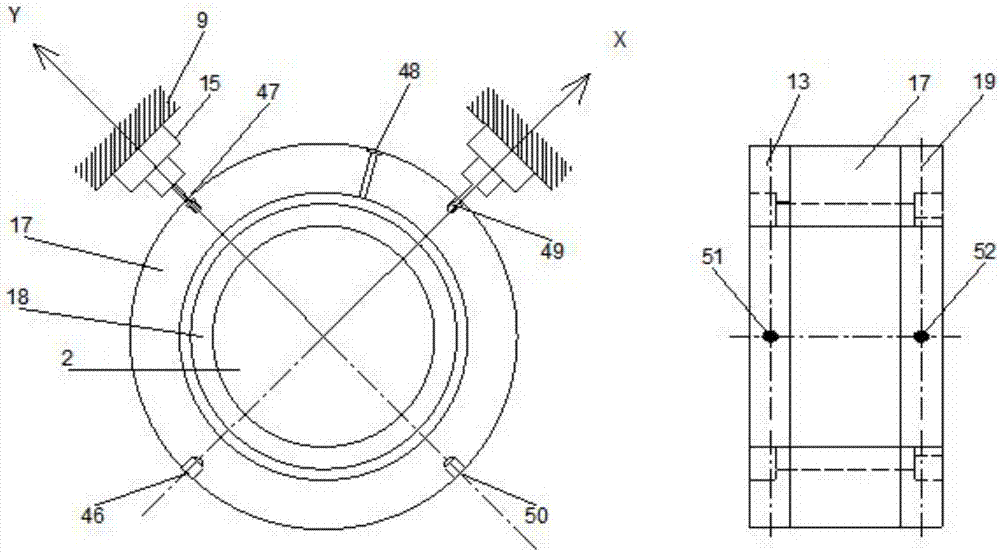

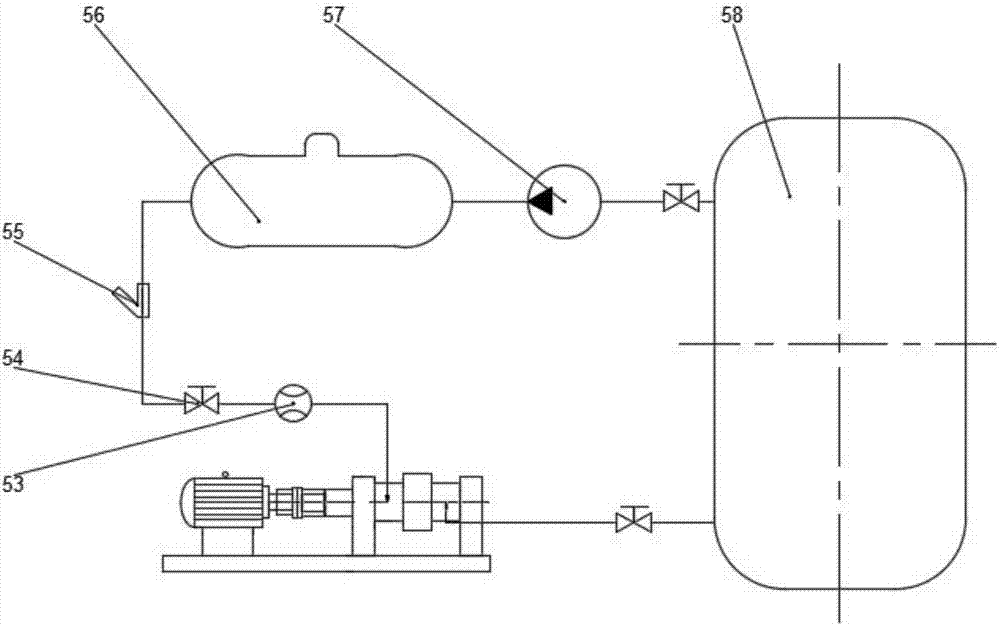

[0069] Embodiment 1, the test device for the characteristic parameters of the dynamic and static excitation force of the sealing ring, such as Figure 1-3 As shown, it includes the main device of the test bench, the mouth ring loading measurement device and the circulation pipeline system.

[0070] Such as figure 1 As shown, the main device of the test bench includes a frame and a main shaft 2, the driving end of the main shaft 2 is connected with a drive motor assembly, and the middle section of the main shaft 2 is equipped with a mouth ring rotor 18 fixedly connected to the main shaft 2; in this embodiment, the main shaft 2 adopts The specific connection method between the stepped shaft and the main shaft 2 and the mouth ring rotor 18 is to set the rotor positioning sleeve 34 set on the main shaft 2 on the right side of the mouth ring rotor 18, and to set the stop gasket on the left side of the mouth ring rotor 18 III42 and round nut III43; one end of the positioning sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com