A fault diagnosis method and system for an automatic production line of prefabricated concrete structures

A fault diagnosis system and automatic production line technology, which is applied in the field of construction industrialization, can solve problems such as time-consuming and laborious, and manual discovery of abnormalities, and achieve the effects of reducing maintenance time, facilitating maintenance, and reducing impact and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in further detail below.

[0029] Fault diagnosis of an automatic production line for a prefabricated concrete structure of the present invention includes the following three steps:

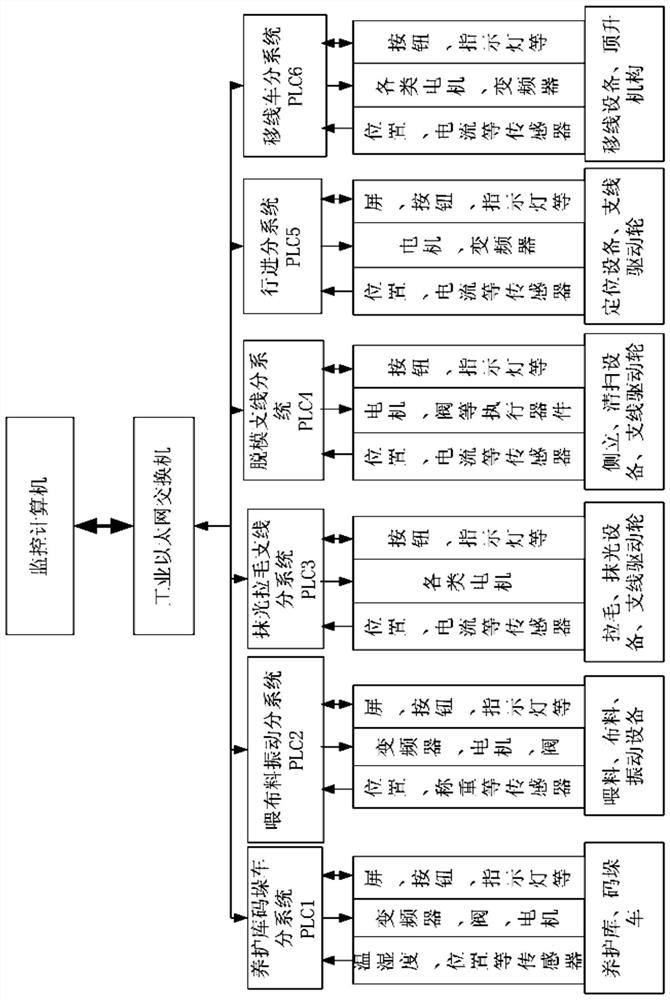

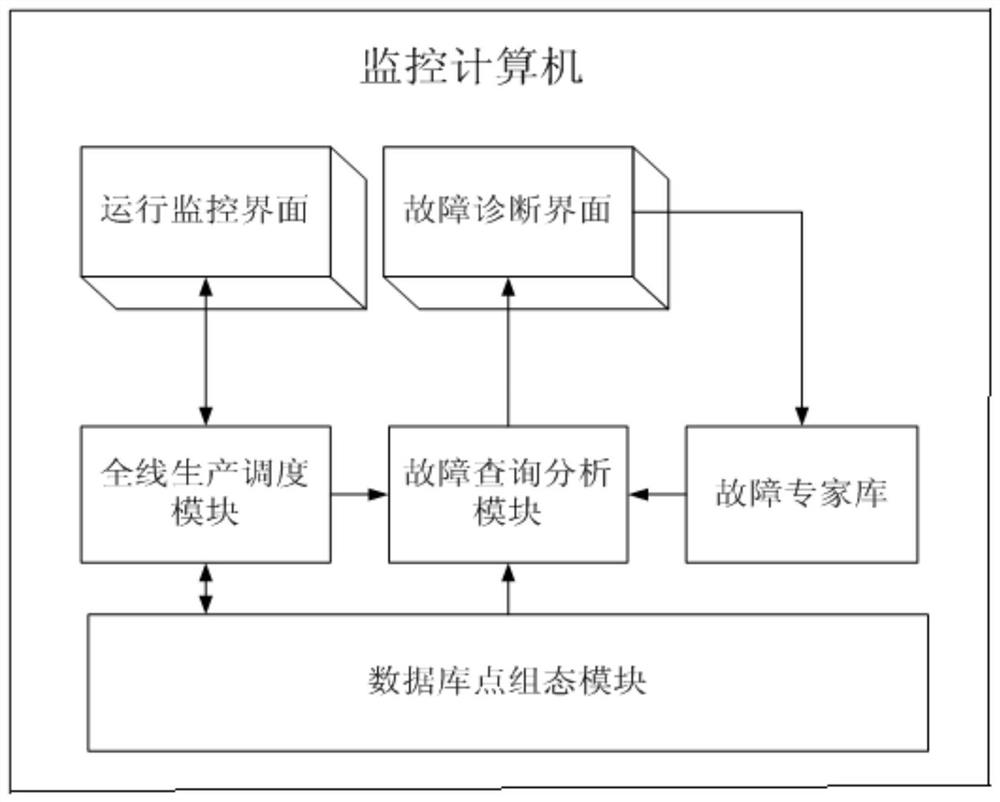

[0030] The first step is to build a PC automatic production line fault hierarchical diagnosis system.

[0031] The PC automatic production line fault hierarchical diagnosis system includes two levels: on-site pre-diagnosis level and centralized analysis level.

[0032] The on-site pre-diagnosis layer is based on the appearance, collects on-site data and focuses on the primary diagnosis of local stations and equipment, and the centralized analysis layer is based on the deep level, focusing on the comprehensive analysis of the system as a whole, inferring the final fault conclusion, and giving processing orders.

[0033] When building the on-site pre-diagnosis layer, including hardware and software support, three parts must be completed.

[0034] One is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com