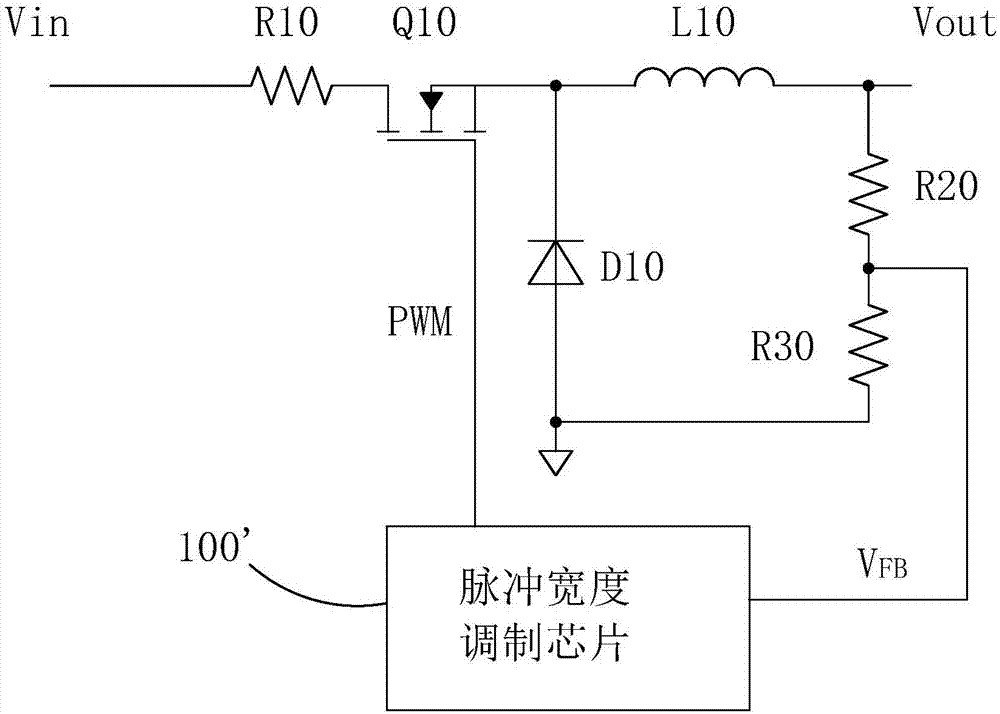

Direct-current voltage conversion circuit and liquid crystal display device

一种直流电压转换、电压转换的技术,应用在输出功率的转换装置、直流功率输入变换为直流功率输出、电气元件等方向,能够解决输入用电元件电压过大、宽度有限、走线大电阻等问题,达到电压保持一致、提升品质、品质好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

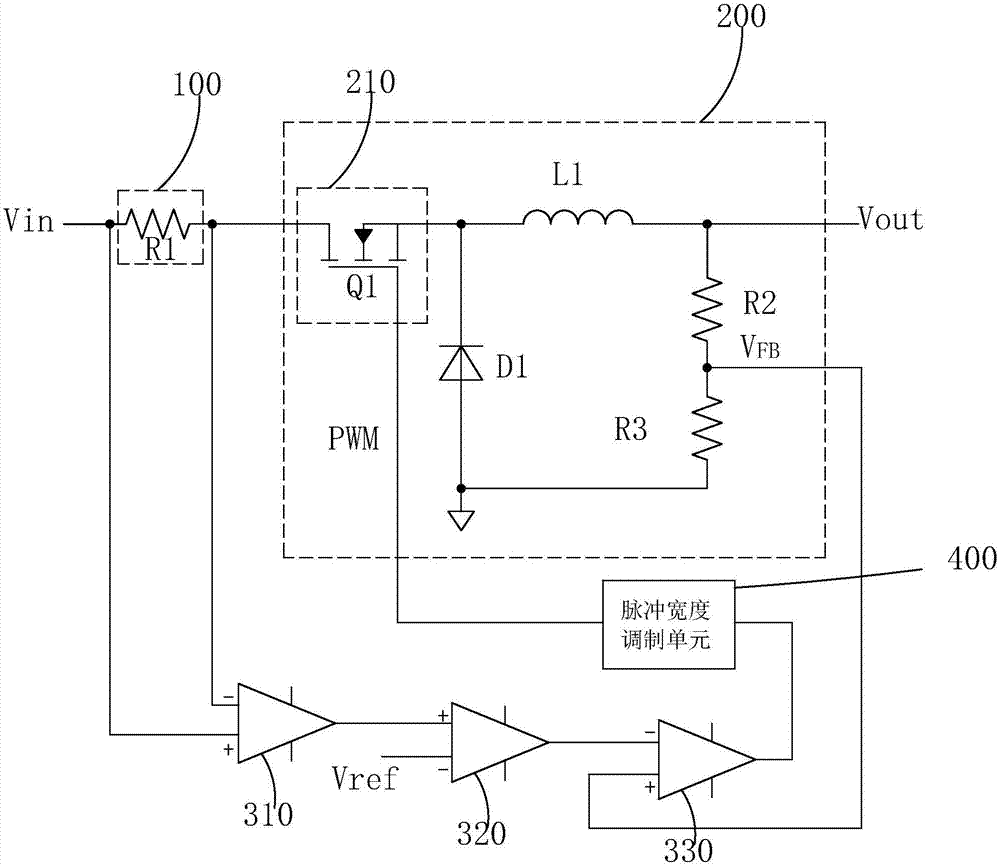

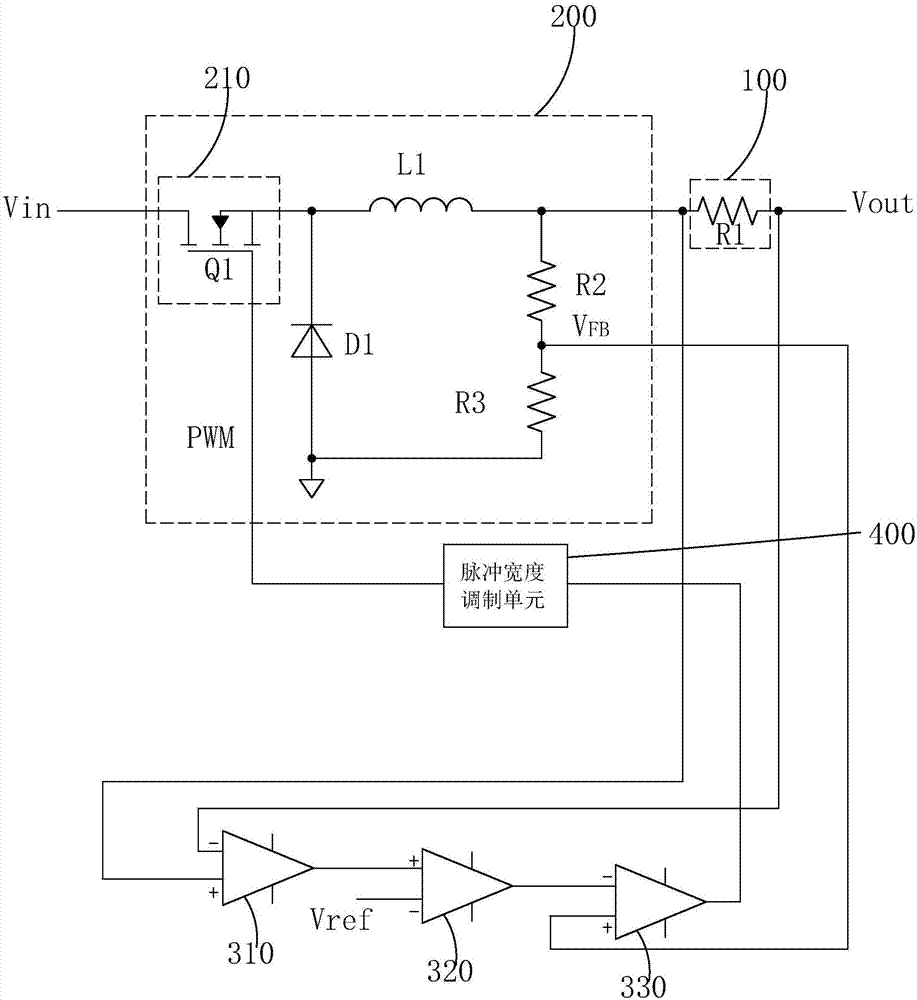

[0031] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0032] The present invention provides a DC voltage conversion circuit, please refer to figure 2 , is a circuit diagram of the first embodiment of the DC voltage conversion circuit of the present invention, the DC voltage conversion circuit includes a voltage dividing unit 100, a voltage conversion unit 200, a first subtractor 310, an adder 320, a second subtractor 330, and a pulse width modulation unit 400;

[0033] In this embodiment, the input terminal of the voltage dividing unit 100 is connected to the input voltage Vin, and the output terminal is electrically connected to the input terminal of the voltage conversion unit 200, and the first output terminal of the voltage conversion unit 200 outputs the output voltage Vout, The second out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com