Portable simulated water seepage performance tester and using method thereof

A portable and measuring instrument technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum, measuring devices, scientific instruments, etc., can solve the problem that the exhaust port cannot well indicate the start time of water infiltration into the asphalt pavement, and the beginning of water infiltration It is difficult to determine the time of entering the road surface, and it is difficult to measure the water seepage coefficient of large voids, etc., so as to avoid errors, measure accurately, and operate easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to further explain the technical means and efficacy adopted by the present invention to achieve the intended invention purpose, the specific implementation, features and efficacy of the portable simulated water seepage performance tester and its use method proposed according to the present invention are described in detail below.

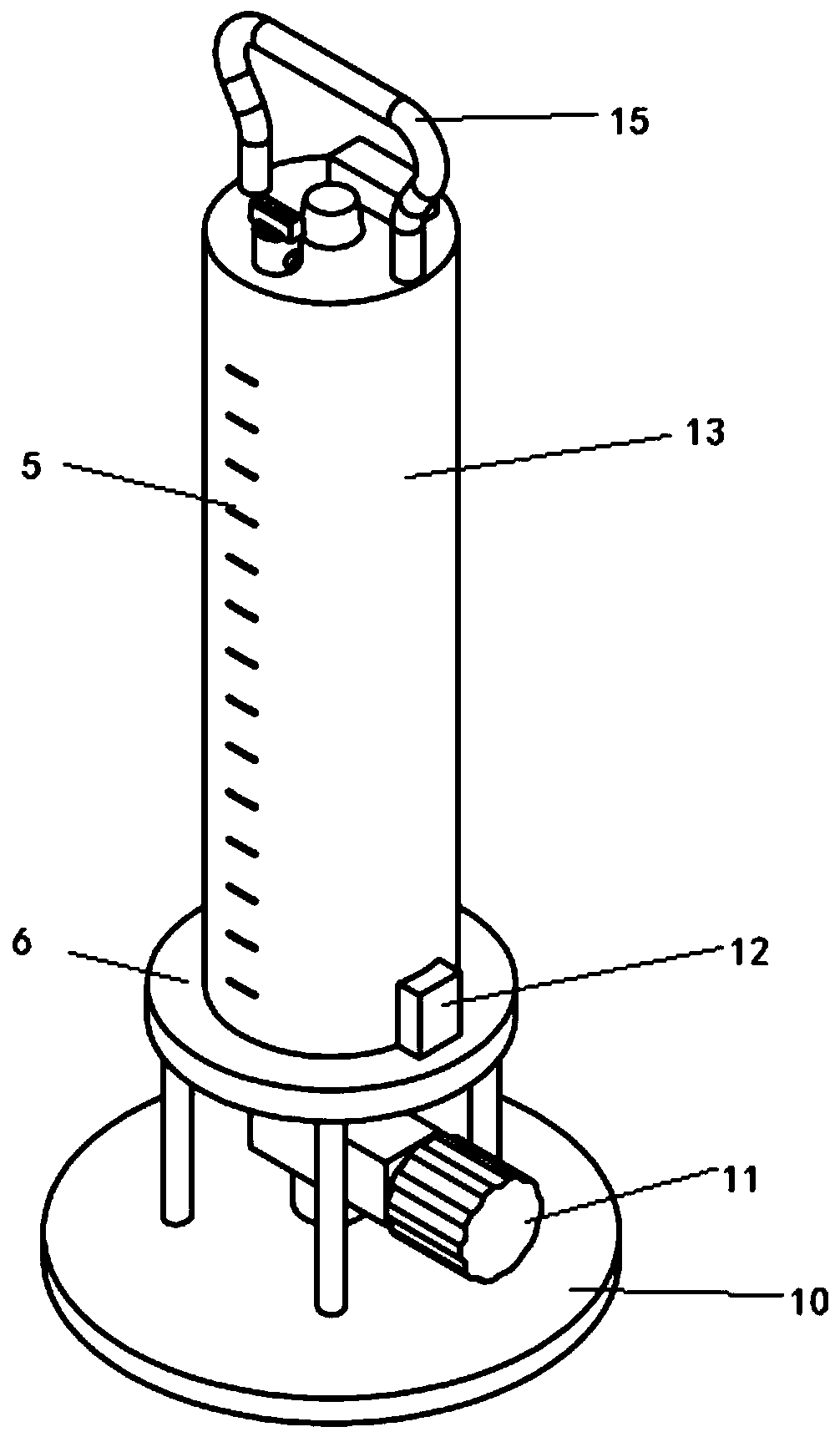

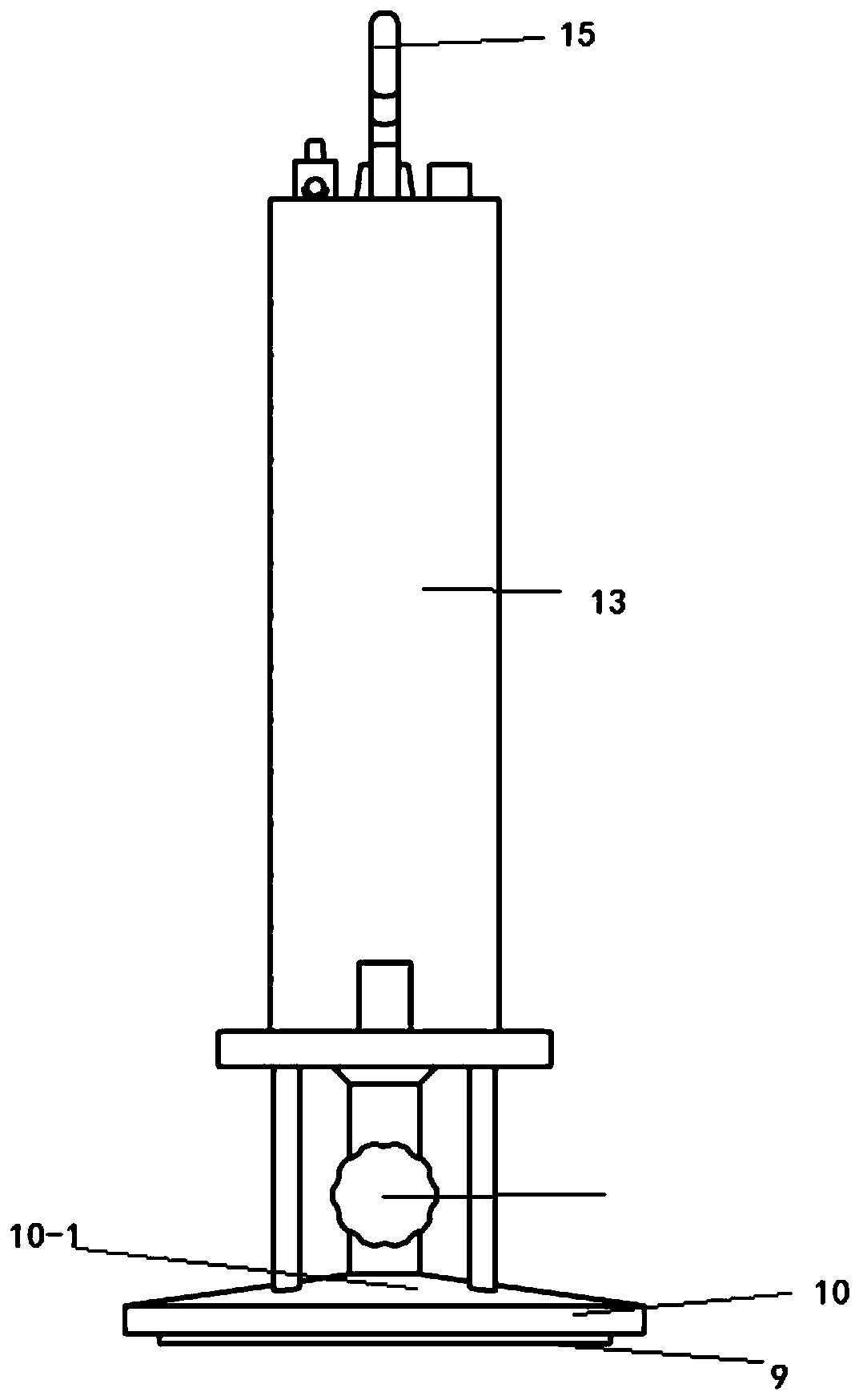

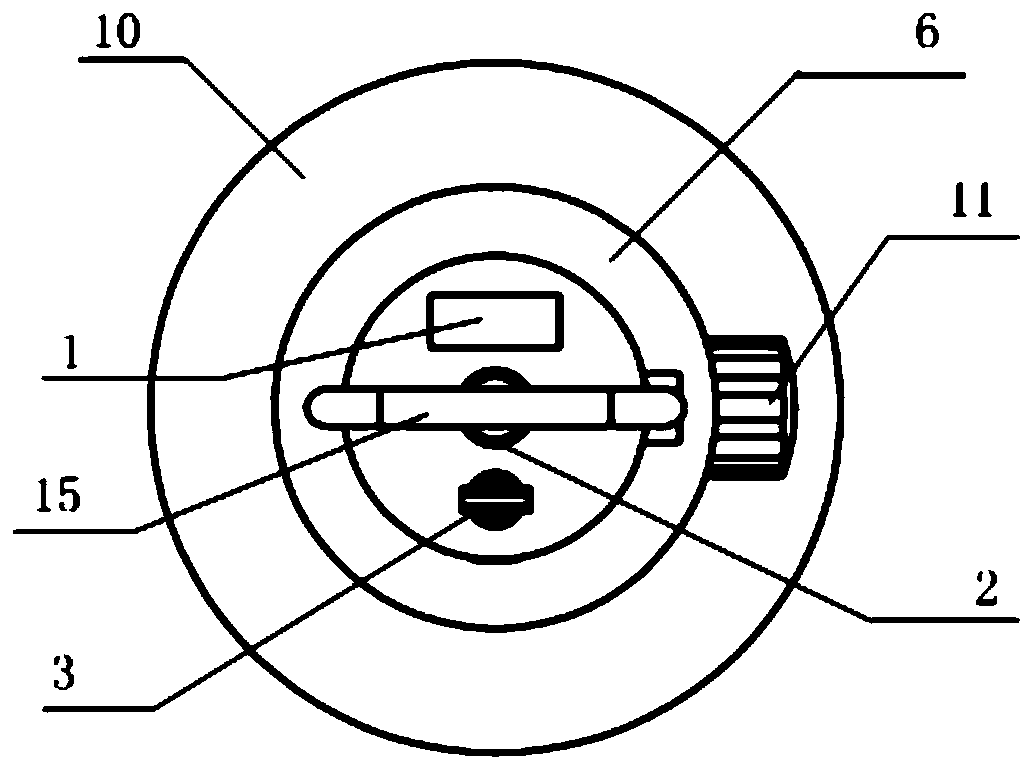

[0051] Such as Figure 1-7 As shown, the present invention discloses a portable simulated water seepage performance tester, comprising: a base 10, which is used to contact with the road surface to be tested to achieve sealing; 8 is connected, and the ventilation pipe 8 is provided with a ventilation switch, and the closure of the ventilation pipe 8 is realized through the ventilation switch; the air pressure slider 14 is arranged inside the measuring cylinder 13 and is perpendicular to the side wall of the measuring cylinder 13, and the air pressure slider 14 and the measurement The side walls of the cylinder 13 are movable seals; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com