Patch type power inductor and manufacturing method thereof

A technology of power inductors and manufacturing methods, which is applied in the field of chip-type power inductors and their manufacturing, can solve problems such as poor heat dissipation performance, poor anti-saturation performance, and reduced reliability, so as to increase the heat dissipation area and improve anti-saturation Ability, life-prolonging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Separately communicated heat dissipation holes are provided on the adjacent surface of the edge of the inductor, and a through hole is provided coaxially with the coil main body.

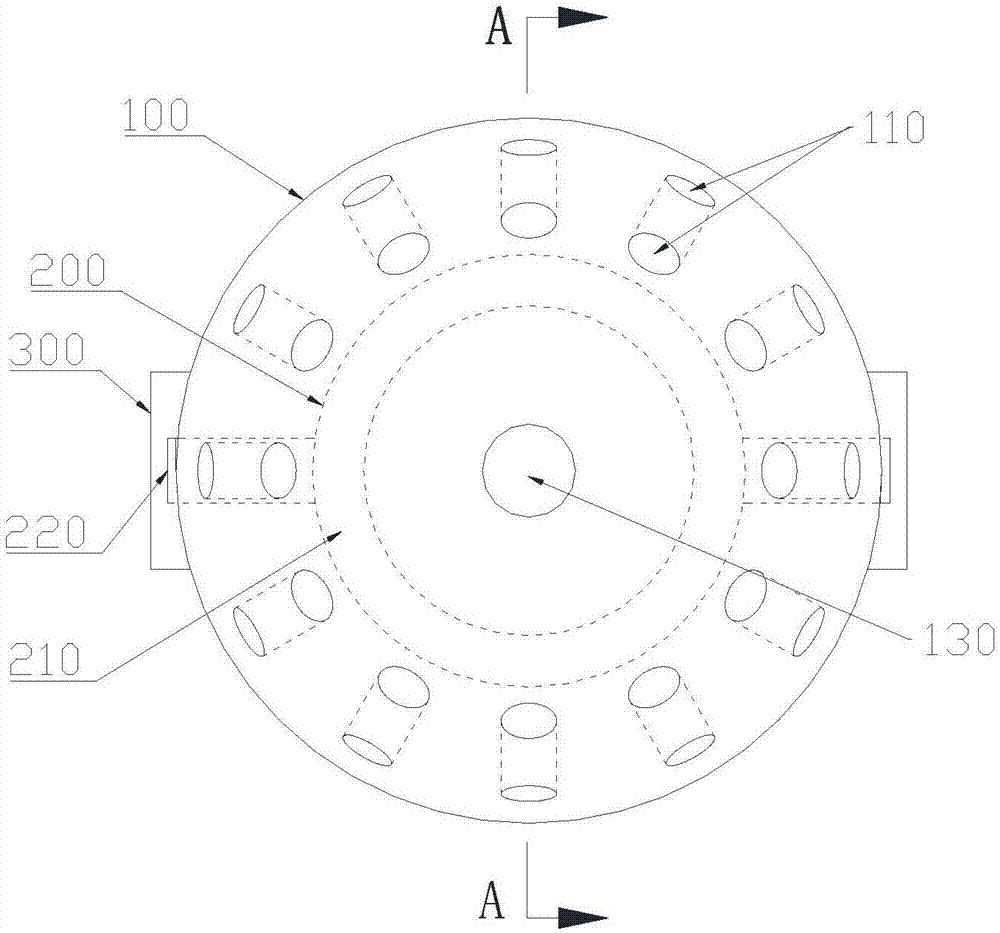

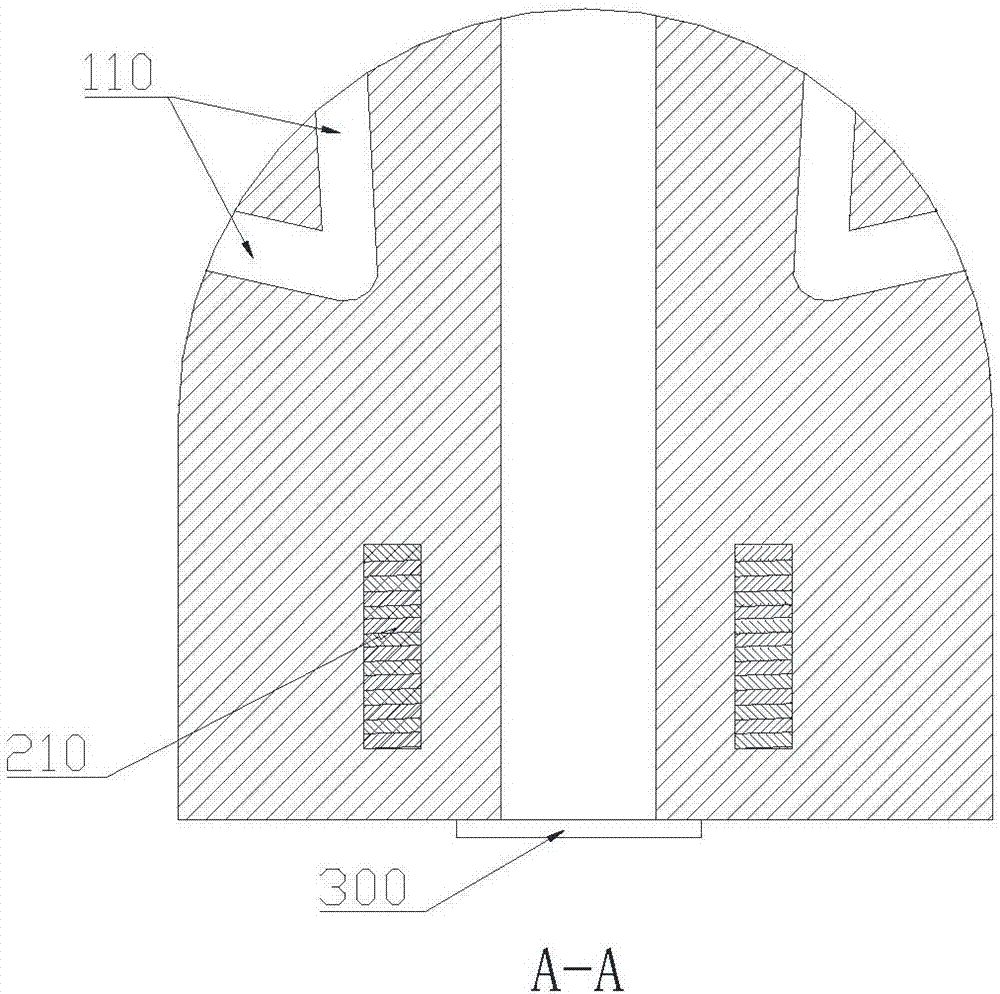

[0071] Such as Figure 5 Figure 6 As shown, the heat dissipation holes are all arranged on the adjacent planes on both sides of the edge, and as shown in Figure 5 As shown, one of the heat dissipation holes 110 at the edge is only connected to one of the heat dissipation holes 120; at the corner, one of the heat dissipation holes 110 can be connected to one or two of the heat dissipation holes 120 to form a stove similar to ventilation structure. Such as Figure 6 As shown, the heat dissipation holes 110 and the heat dissipation holes 120 are vertically arranged. This setting method is mainly aimed at small inductors. The setting method is simple and easy to operate. It can be directly drilled with a short-distance drill. Wherein, the ventilation area or cross-sectional shape of the co...

Embodiment 2

[0074] Compared with the above-mentioned first embodiment, the difference of the second embodiment is that a common communication cooling hole is provided on the adjacent surface at the edge of the inductor.

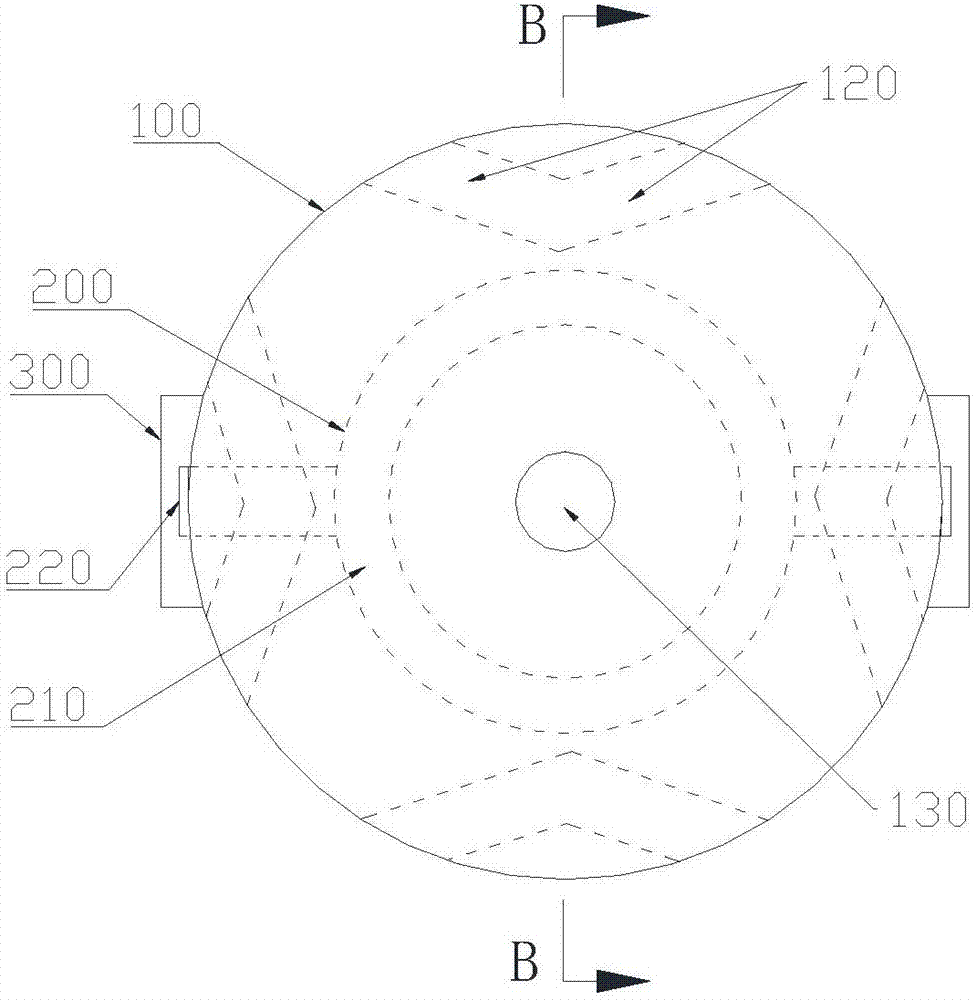

[0075] Such as Figure 7 Figure 8 As shown, the heat dissipation holes are all arranged on adjacent planes on both sides of the edge, and at the edge, one heat dissipation hole 110 communicates with multiple or all of the heat dissipation holes 120 and the heat dissipation holes 110 to form a similar It is based on the ventilation structure of the "stove". This setting method is simple and easy to operate, and can be formed by directly drilling with a drill bit.

[0076] In addition, on the one hand, such an arrangement can make the various heat dissipation holes communicate with each other, so that the surrounding air can be used to cool the places with high heat generation, and the uniformity of heat dissipation of the inductor can be improved; on the other hand, in t...

Embodiment 3

[0078] Compared with the above-mentioned second embodiment, the difference of the third embodiment is that a common communication cooling hole is provided on the adjacent surface at the edge of the inductor and the outer surface of the prism.

[0079] Such as Figure 9 Figure 10 As shown, the outer surface of the prism is covered with the heat dissipation holes, and each of the heat dissipation holes 110 is correspondingly connected with a plurality or all of the heat dissipation holes 120 and the heat dissipation holes 110, so as to form a stove similar to a "stove". ventilation structure. This setting method is simple and easy to operate, and can be formed by directly drilling with a drill bit.

[0080] In addition, such an arrangement can make the heat dissipation holes communicate with each other, so that the surrounding air can be used to cool the places with high heat generation, and the heat dissipation requirements of various parts of the inductor can be balanced; a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com