Feed mixing production machine for animals

A technology for producing machines and feeds, which is applied to mixers, mixers with rotating stirring devices, feeds, etc. It can solve the problems of uneven mixing and inability to ensure sufficient mixing of feeds, so as to reduce the amount of agglomeration and avoid material mixing Unevenness, the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

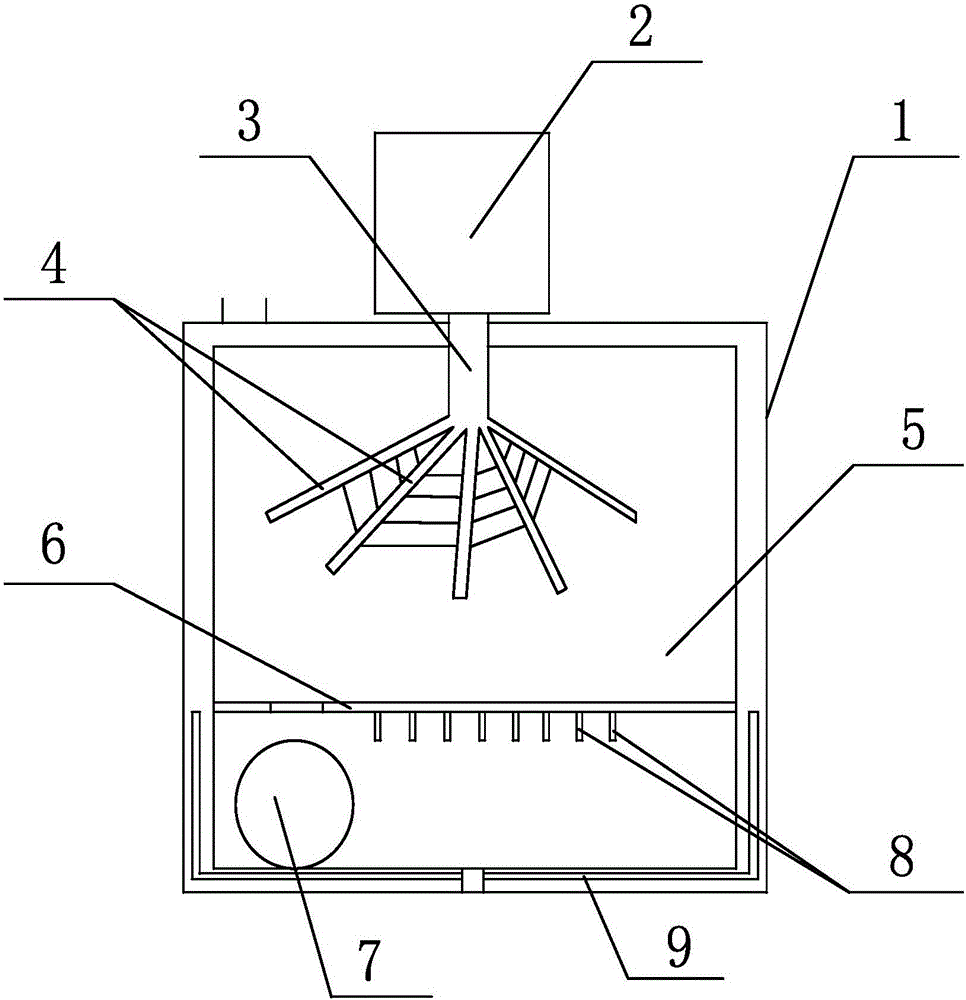

[0022] Such as figure 1 As shown, the feed mixing production machine for animals of the present invention includes a mixing box 1, a mixing cavity 5 is provided in the mixing box 1, a feeding port is provided at the top of the mixing box 1, and a mixing chamber 1 is provided above the mixing box 1. Storage box 2, the bottom of the storage box 2 is connected with a discharge pipe 3, the discharge pipe 3 extends into the mixing box 1 and rotates around its own axis, and the bottom of the discharge pipe 3 rotates around its circumferential direction There are a plurality of evenly distributed stirring tubes 4 which are arranged in a slanted manner in turn, a steel wire mesh is arranged between two adjacent uniformly distributed stirring tubes 4, a partition 6 is arranged in the mixing chamber 5, and the partition 6 divides the mixing chamber 5 is divided into two upper and lower cavities, the separator 6 is provided with a feed opening, the lower cavity is provided with a rolling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com