All-terrain self-adaptive shock absorbing wheel

A wheel and axle technology, applied in the field of all-terrain adaptive damping wheels, can solve the problems of complicated maintenance and maintenance, low buffer performance and low deformation capacity, and achieve the advantages of simple maintenance, reduction of the dead weight of the vehicle body, and simplification of the vehicle structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Further illustrate the present invention below in conjunction with accompanying drawing and embodiment

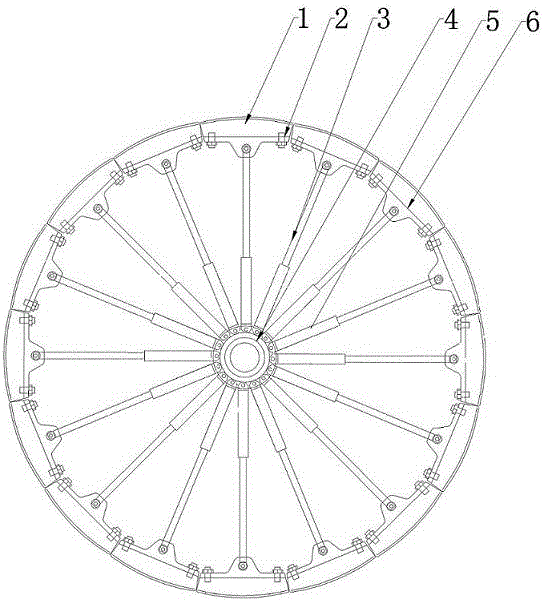

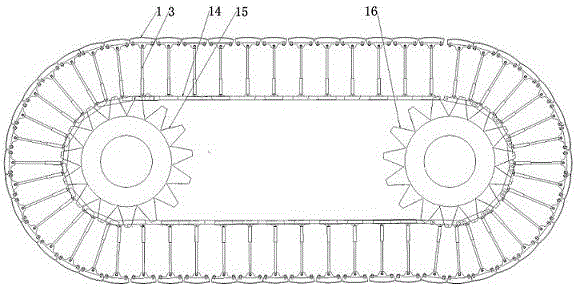

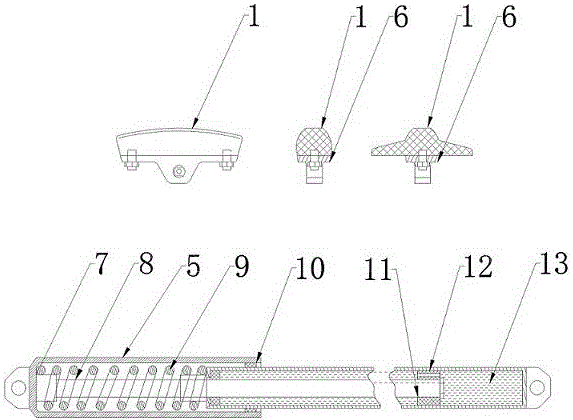

[0012] like figure 1 As shown, the present invention includes a wheel shaft 4, a retractable wheel spoke 3, and a wheel plate 6, and the fixed bolt 2 is fixedly connected to the retractable wheel spoke 3 between the wheel shaft 4 and the wheel plate 6, and at least 3 groups of wheel plates 6 and the retractable wheel spoke 3 Around the wheel shaft 4 to form a circular wheel, the end of the retractable spoke 3 with the dust-proof sleeve is connected to the wheel shaft, so that the installation can prevent the liquid medium from leaking from the seal between the rubber and the hydraulic cylinder under the action of centrifugal force when the wheel rotates The palm surface 1 of the wheel and the fixing bolt 2 can be thermally molded into one at one time, or the bolt can pass through the hole on the palm surface 1 of the wheel, and then be fastened on the wheel plate 6; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com