Method for separating and purifying glutaric acid in mixed binary acid by low-carbon halogenated hydrocarbon

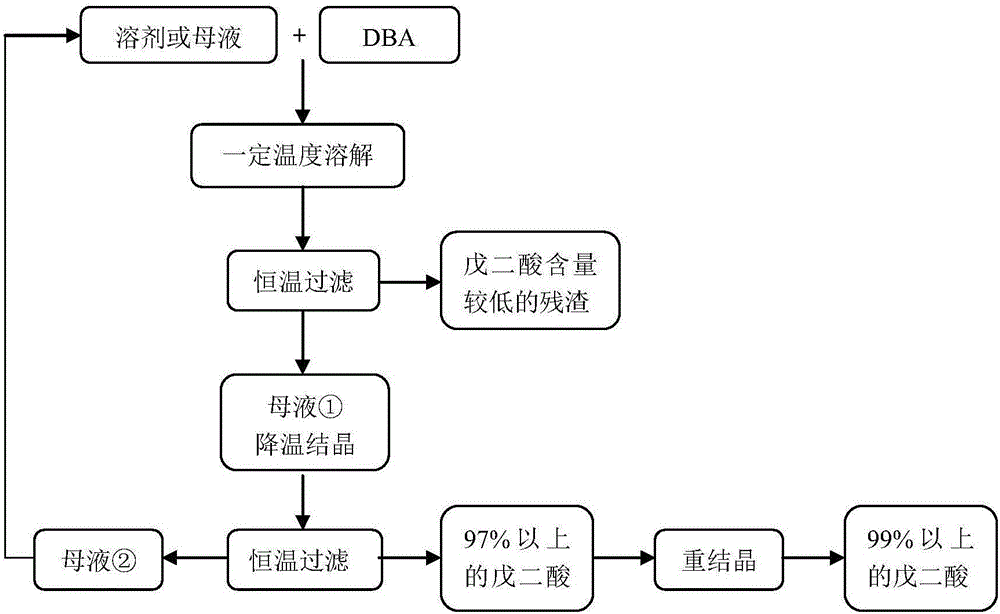

A technology of mixing dibasic acid and carbon halogenated alkane, which is applied in the separation/purification of carboxylic acid compounds, organic chemistry and other directions, can solve the problems of high cost, low product yield and complicated process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Set the temperature of the constant temperature water bath to 59.4°C. After the temperature of the jacket of the dissolution kettle rises to this temperature, add 1530g of DBA raw material powder of 40 meshes after grinding and sieving and 3369ml of 1,2-dibromoethane solvent into the dissolution kettle and stir to dissolve. The speed is set to 350r / min. After the temperature displayed by the thermocouple in the dissolution kettle rises to about 59.2°C, start timing. After dissolving for 1 hour, heat-retain and filter. The filter cake is a DBA mixture, which will be used as a by-product after drying.

[0031] The filtrate was introduced into a crystallization kettle with a jacket temperature of 61.4°C, and when there were no particles in the filtrate and the thermocouple of the crystallization kettle showed that the temperature was stable at 61.2°C, the crystallization began by cooling down. During the crystallization process, the stirring speed was 290r / min, and the coo...

Embodiment 2

[0034] Set the temperature of the constant temperature water bath to 63.5°C. After the temperature of the jacket of the dissolution kettle rises to this temperature, add 1530g of DBA raw material powder of 40 meshes after grinding and sieving and 4927ml of 1,2,3-trichloropropane solvent into the dissolution kettle and stir to dissolve. The stirring speed was set at 350r / min. After the thermocouple in the dissolution kettle shows that the temperature rises to about 63.3°C, start timing. After dissolving for 1 hour, heat-preserve and filter. The filter cake is a DBA mixture, which will be used as a by-product after drying.

[0035] The filtrate was introduced into a crystallization kettle with a jacket temperature of 65.5°C. When there were no particles in the filtrate and the thermocouple of the crystallization kettle showed that the temperature was stable at 65.3°C, the crystallization began to cool down. During the crystallization process, the stirring speed was 290r / min, and...

Embodiment 3

[0038] Set the temperature of the constant temperature water bath to 57.4°C. After the temperature of the jacket of the dissolution kettle rises to this temperature, add 1530g of DBA raw material powder of 40 meshes after grinding and sieving and 4284ml of 1,4-dichlorobutane solvent into the dissolution kettle and stir to dissolve. The speed is set to 350r / min. After the temperature displayed by the thermocouple in the dissolution kettle rises to about 57.2°C, start timing. After dissolving for 1 hour, heat-retain and filter. The filter cake is a DBA mixture, which will be used as a by-product after drying.

[0039] The filtrate was introduced into a crystallization kettle with a jacket temperature of 59.4°C, and when there was no particulate matter in the filtrate and the thermocouple of the crystallization kettle showed that the temperature was stable at 59.2°C, the cooling crystallization began. During the crystallization process, the stirring speed was 290r / min, and the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com