Latex quilt production process

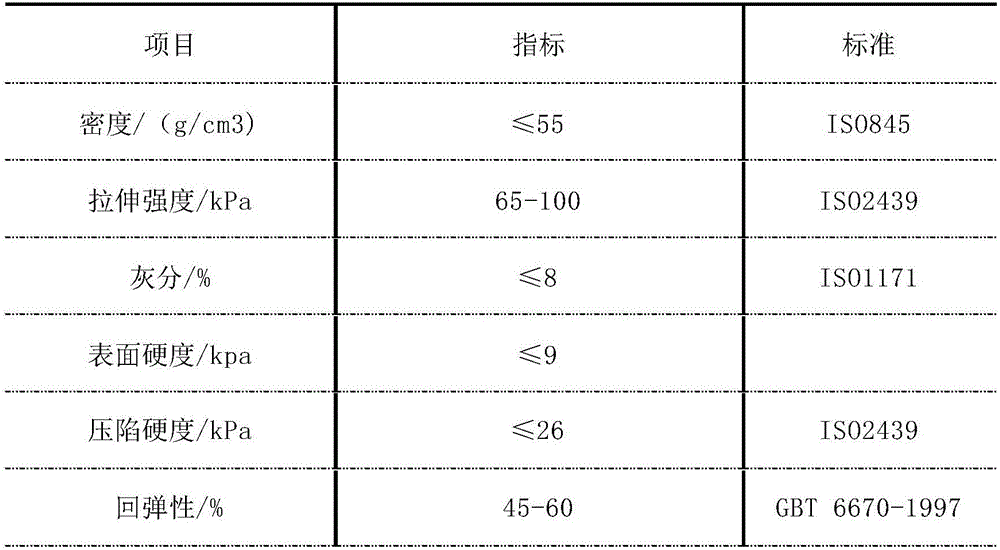

A production process and latex technology, which is applied in the field of automatic density meter for storage tanks, can solve the problems of poor flexibility and poor air permeability of latex, and achieve the effect of low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The purpose of this embodiment is to provide a latex quilt production process, which can effectively solve the problems of poor latex quilt flexibility and poor air permeability in the prior art.

[0027] Hereinafter, embodiments will be described with reference to the drawings. In addition, the embodiments shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configuration shown in the following embodiments are not limited to what is necessary as a solution to the invention described in the claims.

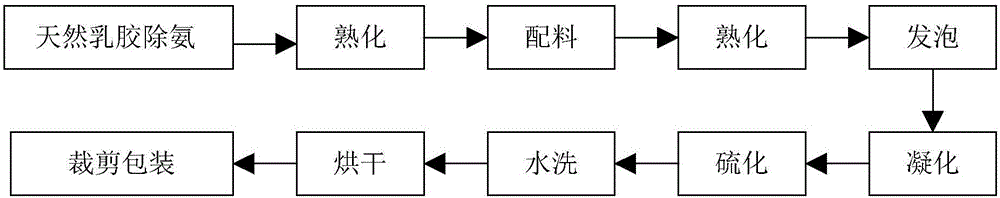

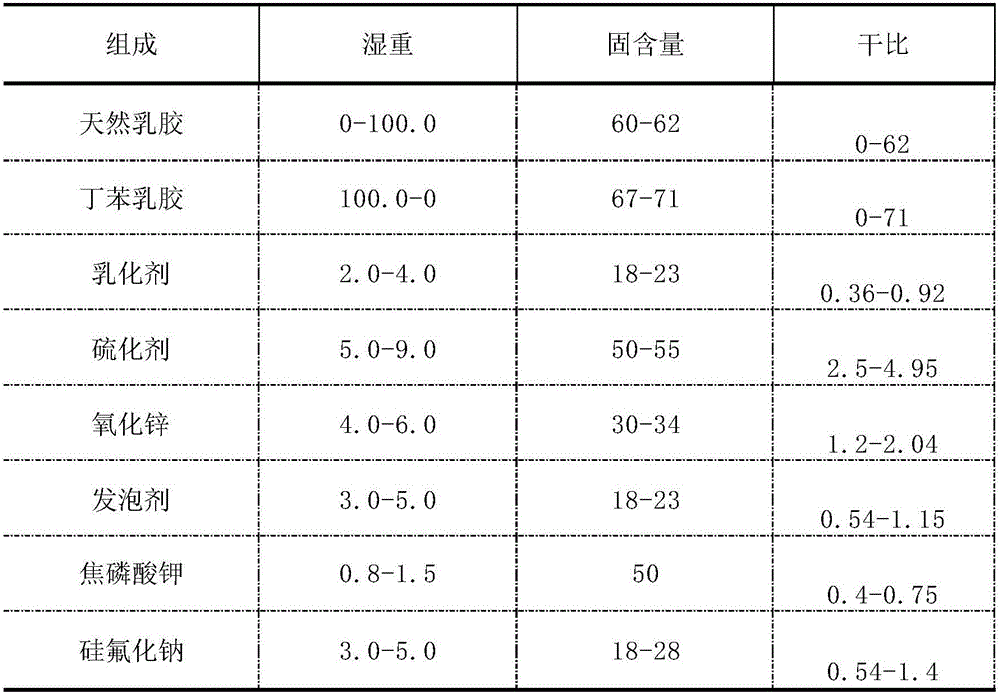

[0028] In the latex production process provided in this embodiment, the natural latex is first subjected to ammonia removal treatment, and then the ammonia-removed natural latex is cured. Then the batching is carried out, and the matured natural latex is used as one of the raw materials for batching, and then the processes of curing, foaming, coagulation, vulcanization, washing, drying, cutting and packag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com